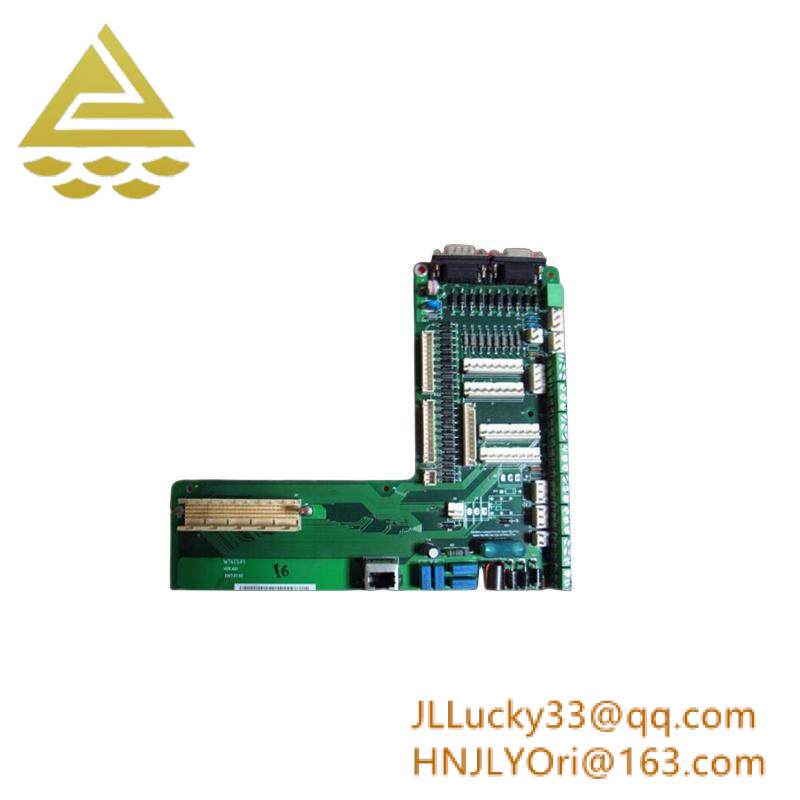

The HIMA M3443 is a critical safety controller engineered for high-integrity applications in industrial automation, providing fail-safe operation in mission-critical environments. As part of HIMA’s SIL 3-certified safety portfolio, this controller serves as the backbone of safety instrumented systems (SIS) across industries such as oil and gas, chemical processing, and power generation. Its primary role is to monitor processes, detect hazardous conditions, and execute emergency shutdowns (ESD) or safety interlocks to prevent accidents. What makes the M3443 invaluable is its triple modular redundant (TMR) architecture, which ensures continuous operation even in the event of component failures. By delivering deterministic performance and fault tolerance, the controller minimizes downtime and protects personnel, assets, and the environment.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | HIMA M3443 |

| Manufacturer | HIMA |

| Product Type | Safety Controller |

| Safety Integrity Level | SIL 3 (IEC 61508), PL e (ISO 13849) |

| Architecture | Triple Modular Redundancy (TMR) |

| Processing Speed | 1ms typical response time |

| I/O Channels | Up to 512 digital/analog I/O points |

| Communication Protocols | PROFIBUS DP, HART, Modbus TCP/IP |

| Power Supply | 24VDC (dual redundant inputs) |

| Operating Temperature | -20°C to +60°C |

| Humidity Range | 5-95% non-condensing |

| Dimensions (WxHxD) | 483mm x 177mm x 220mm |

| Weight | 8.5kg |

| Mounting | 19-inch rack mounting |

| Protection Rating | IP20 (front) / IP54 (with optional cover) |

| Certifications | IEC 61508, EN 50156, ATEX, IECEx |

Key Features and Benefits

The M3443’s TMR architecture features three independent processor channels that vote on every output, ensuring high availability and fault tolerance. This design allows the controller to continue operating even with multiple failures, making it ideal for applications where safety cannot be compromised. The controller’s high-speed processing capabilities enable rapid response to critical events, reducing the risk of incidents in fast-paced industrial environments.

The M3443’s TMR architecture features three independent processor channels that vote on every output, ensuring high availability and fault tolerance. This design allows the controller to continue operating even with multiple failures, making it ideal for applications where safety cannot be compromised. The controller’s high-speed processing capabilities enable rapid response to critical events, reducing the risk of incidents in fast-paced industrial environments.

Advanced diagnostic tools embedded in the M3443 continuously monitor system health, detecting potential issues before they escalate. This proactive approach to maintenance minimizes unplanned downtime and extends the controller’s operational life. The controller’s modular design allows for easy expansion and integration with existing infrastructure, reducing upgrade costs and downtime during system modifications.

HIMA’s SafeEthernet technology ensures secure and reliable communication between the M3443 and other safety-critical devices, enabling seamless integration into complex automation networks. The controller’s compliance with international safety standards, such as IEC 61508 and ATEX, ensures compatibility with global industrial requirements, simplifying certification processes for end-users.

Application Scenarios

In oil and gas refineries, the M3443 is deployed in emergency shutdown systems to monitor pressure, temperature, and flow rates, triggering safety protocols in the event of anomalies. Its TMR architecture ensures reliable operation in harsh environments, where exposure to corrosive substances and extreme temperatures is common. In chemical plants, the controller manages safety interlocks for reactors and storage tanks, preventing overpressure and chemical leaks.

In oil and gas refineries, the M3443 is deployed in emergency shutdown systems to monitor pressure, temperature, and flow rates, triggering safety protocols in the event of anomalies. Its TMR architecture ensures reliable operation in harsh environments, where exposure to corrosive substances and extreme temperatures is common. In chemical plants, the controller manages safety interlocks for reactors and storage tanks, preventing overpressure and chemical leaks.

For power generation facilities, the M3443 controls critical safety functions in nuclear, fossil fuel, and renewable energy plants. Its high-integrity design ensures safe operation during normal and abnormal conditions, protecting against catastrophic failures. In transportation infrastructure, such as tunnels and bridges, the controller manages ventilation systems and fire suppression, ensuring public safety in the event of emergencies.

Related Models

- HIMA HIMatrix S5-400F – Scalable safety controller for mid-sized applications.

- HIMA HIQuad H51q – Quadruple redundant safety system for ultra-high availability.

- HIMA F6221 – I/O module for expanding digital input/output capacity.

- HIMA HIMax XMR – Next-generation safety controller with enhanced processing power.

- HIMA HIMguard – Safety gateway for secure communication between safety and non-safety systems.

Installation and Maintenance

Installing the M3443 requires a stable 19-inch rack mount in a climate-controlled enclosure to protect against dust, moisture, and extreme temperatures. Adequate ventilation (100mm clearance) around the controller ensures proper heat dissipation. Prior to installation, verify that the dual redundant power supplies are properly configured and grounded according to local electrical codes. The controller’s plug-and-play design simplifies wiring, with color-coded terminals for easy identification.

Installing the M3443 requires a stable 19-inch rack mount in a climate-controlled enclosure to protect against dust, moisture, and extreme temperatures. Adequate ventilation (100mm clearance) around the controller ensures proper heat dissipation. Prior to installation, verify that the dual redundant power supplies are properly configured and grounded according to local electrical codes. The controller’s plug-and-play design simplifies wiring, with color-coded terminals for easy identification.

Regular maintenance involves visual inspections for physical damage, cleaning air filters (if applicable), and verifying firmware updates via HIMA’s Safety Configuration Studio. Diagnostic routines, accessible through the controller’s web interface, should be run weekly to check for sensor drift, communication errors, or component wear. Under normal operating conditions, the M3443 has a recommended service life of 15 years, with redundant components ensuring continuous operation during scheduled maintenance.

Leave a comment

Your email address will not be published. Required fields are marked *