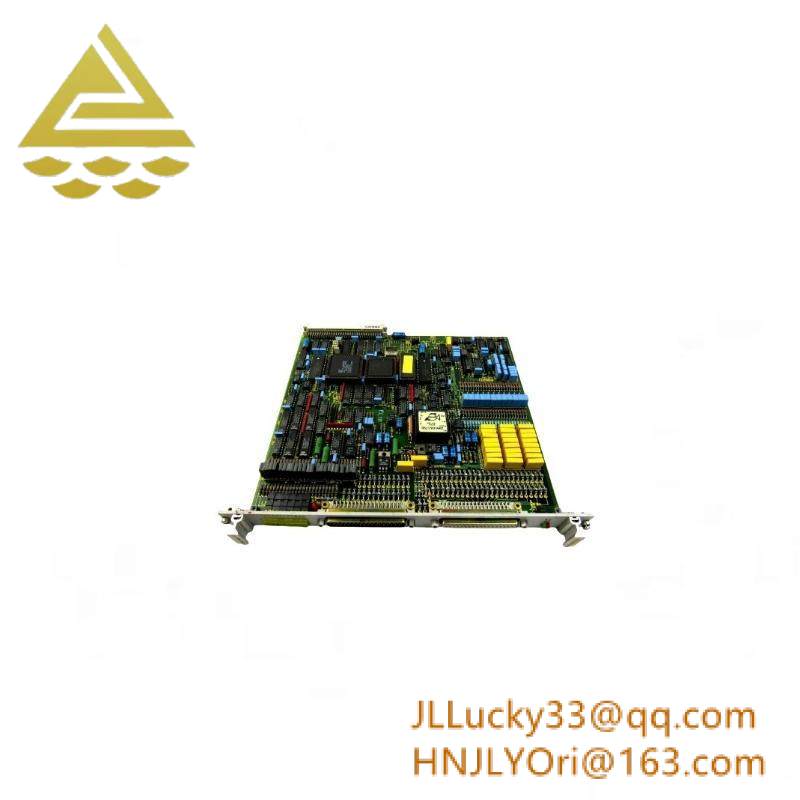

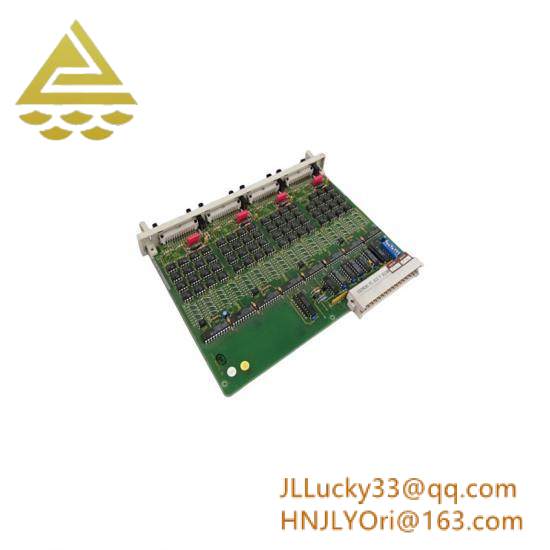

The HIMA K9203 is a high-integrity safety relay module designed for critical applications in industrial automation, providing fail-safe operation and reliable circuit protection. As part of HIMA’s extensive portfolio of safety solutions, this module serves as a vital component in safety instrumented systems (SIS), emergency shutdown (ESD) systems, and fire and gas detection networks. Its role in an automation setup is to monitor safety-critical signals and execute predefined actions, such as isolating power or triggering alarms, to prevent hazardous situations. What sets the K9203 apart is its dual-channel design with self-monitoring capabilities, which ensures continuous operation while maintaining high safety integrity. By combining robust construction with advanced diagnostic features, the module minimizes false trips and downtime, making it an essential choice for industries where safety and reliability are paramount.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | HIMA K9203 |

| Manufacturer | HIMA |

| Product Type | Safety Relay Module |

| Safety Integrity Level | SIL 3 (IEC 61508), PL e (ISO 13849) |

| Channel Configuration | 2NO+2NC (Normally Open/Normally Closed) |

| Rated Current | 10A per channel |

| Contact Material | Silver alloy |

| Operating Voltage | 24VDC ±20% |

| Power Consumption | <5W |

| Response Time | <10ms |

| Operating Temperature | -25°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Dimensions (WxHxD) | 22.5mm x 100mm x 115mm |

| Weight | 0.2kg |

| Mounting | DIN rail (EN 60715) |

| Protection Rating | IP20 |

| Certifications | IEC 61508, UL 508, ATEX, IECEx |

Key Features and Benefits

The K9203 excels in providing reliable circuit protection through its redundant design, which includes two independent channels that monitor each other for faults. This dual-channel architecture ensures that any single failure is detected and annunciated without affecting the module’s ability to perform its safety function. The module’s high switching capacity (10A per channel) allows it to directly control heavy loads, eliminating the need for additional intermediate relays and simplifying system design.

The K9203 excels in providing reliable circuit protection through its redundant design, which includes two independent channels that monitor each other for faults. This dual-channel architecture ensures that any single failure is detected and annunciated without affecting the module’s ability to perform its safety function. The module’s high switching capacity (10A per channel) allows it to directly control heavy loads, eliminating the need for additional intermediate relays and simplifying system design.

Advanced self-diagnostic capabilities continuously monitor the K9203 ’s internal components, including contacts, coils, and power supplies, ensuring early detection of potential issues. This proactive approach reduces the risk of unexpected failures and enables predictive maintenance, minimizing downtime and maintenance costs. The module’s low power consumption and wide operating temperature range (-25°C to +70°C) make it suitable for use in harsh industrial environments, from chemical plants to offshore platforms.

The K9203’s modular design allows for easy integration into existing systems, with plug-in terminals that simplify wiring and reduce installation time. The module’s compliance with international safety standards, such as IEC 61508 and ATEX, ensures compatibility with global industrial requirements, making it a trusted choice for safety-critical applications worldwide.

Application Scenarios

In chemical processing plants, the K9203 is used to monitor pressure and temperature sensors in reactors, triggering emergency shutdowns if parameters exceed safe limits. Its fail-safe design ensures that even in the event of a component failure, the module will default to a safe state, preventing potential disasters. In oil and gas facilities, the module controls isolation valves in pipelines, shutting off flow in the event of leaks or overpressure situations.

In chemical processing plants, the K9203 is used to monitor pressure and temperature sensors in reactors, triggering emergency shutdowns if parameters exceed safe limits. Its fail-safe design ensures that even in the event of a component failure, the module will default to a safe state, preventing potential disasters. In oil and gas facilities, the module controls isolation valves in pipelines, shutting off flow in the event of leaks or overpressure situations.

For power generation, the K9203 manages safety interlocks in turbine control systems, ensuring safe operation during startup, shutdown, and normal operation. In transportation infrastructure, such as railway crossings and airport fueling systems, the module provides fail-safe control of warning signals and emergency stop functions, protecting both personnel and assets.

Related Models

- HIMA K9201 – Single-channel safety relay for basic safety applications.

- HIMA K9205 – Enhanced version with additional diagnostic features and higher current ratings.

- HIMA K9210 – Multi-channel safety relay module with 4NO+4NC configuration.

- HIMA K9220 – Safety relay with integrated test button for manual function checks.

- HIMA K9230 – High-speed safety relay for applications requiring ultra-fast response times.

Installation and Maintenance

Installing the K9203 requires a DIN rail (EN 60715) mounting in a well-ventilated enclosure to prevent overheating. The module should be positioned away from sources of electromagnetic interference (EMI), such as large motors or transformers, to ensure reliable operation. Prior to installation, verify that the power supply meets the specified voltage range and that all wiring connections are secure. The module’s plug-in terminals allow for quick and easy installation, reducing downtime during system upgrades.

Installing the K9203 requires a DIN rail (EN 60715) mounting in a well-ventilated enclosure to prevent overheating. The module should be positioned away from sources of electromagnetic interference (EMI), such as large motors or transformers, to ensure reliable operation. Prior to installation, verify that the power supply meets the specified voltage range and that all wiring connections are secure. The module’s plug-in terminals allow for quick and easy installation, reducing downtime during system upgrades.

Regular maintenance of the K9203 involves visual inspections for signs of physical damage, such as cracked housings or loose connections. The module’s diagnostic LEDs should be checked during routine system checks to ensure they indicate normal operation. Firmware updates, if available, should be performed periodically to enhance functionality and address any known issues. Under normal operating conditions, the K9203 has a recommended service life of 10 years, with contact wear being the primary factor influencing replacement intervals.

Leave a comment

Your email address will not be published. Required fields are marked *