Operating Range:Flexible arm length configurations up to 2,000 mm

Payload Capacity:Up to 6 kg for IRB2600, up to 7 kg for IRB6700, up to 4 kg for IRB4400

Speed:Up to 300 mm/s for all models

Accuracy:±0.02 mm repeatability for precise operations

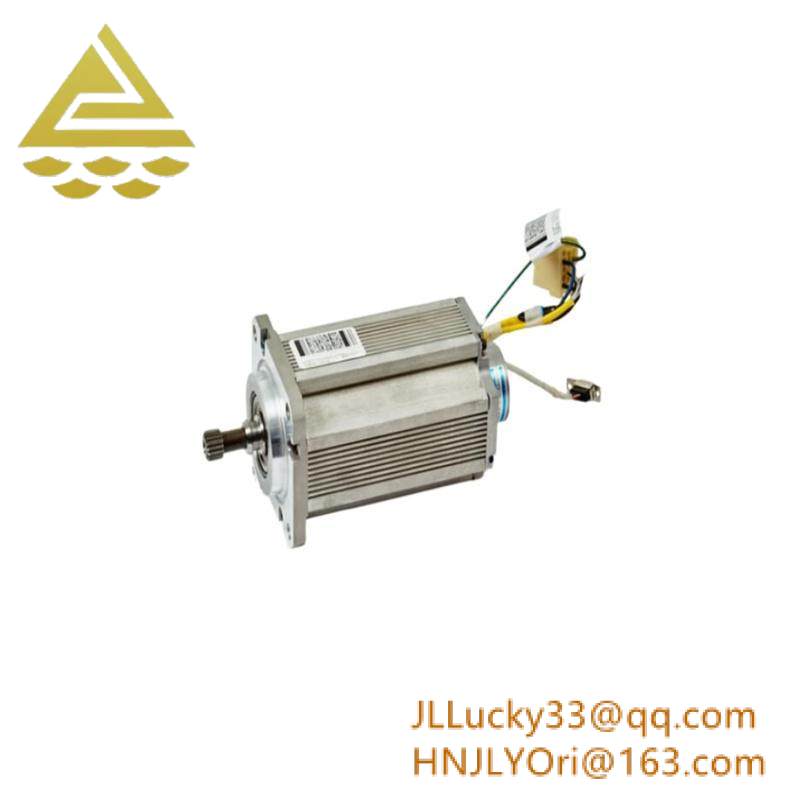

Servo Motors:High-torque, brushless DC motors for enhanced performance

Safety Features:Built-in safety systems for compliance with ISO standards

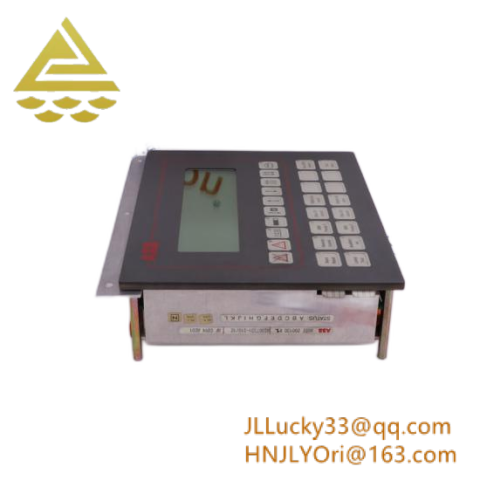

Communication Protocols:Supports EtherCAT, CANopen, and other industry-standard interfaces

Environmental Compatibility:Designed for operation in harsh industrial environments

Certifications:CE, UL, and ISO 9001 compliant

ABB‘s IRB6700-200, IRB2600, and IRB4400 robotic arm modules offer unparalleled precision and flexibility, making them indispensable in high-end manufacturing processes. These state-of-the-art solutions are engineered to handle complex assembly tasks with ease, ensuring both efficiency and safety in your production line.

Featuring high-speed brushless DC servo motors, these robotic arms deliver exceptional performance with a payload capacity of up to 6 kg for IRB2600, up to 7 kg for IRB6700, and up to 4 kg for IRB4400, ensuring they can handle a variety of materials and components.

With a ±0.02 mm repeatability accuracy, these modules guarantee consistent and accurate operations, crucial for achieving high-quality outputs in industries such as automotive, electronics, and pharmaceuticals.

Equipped with built-in safety systems that comply with ISO standards, these robotic arms enhance operational safety without compromising on productivity. They are designed to withstand the rigors of industrial environments, ensuring reliable performance over extended periods.

Supporting a range of communication protocols including EtherCAT and CANopen, these modules seamlessly integrate with existing automation systems, offering flexibility and compatibility with various control platforms. This feature ensures easy installation and integration into diverse manufacturing setups.

There are no reviews yet.