Product Overview

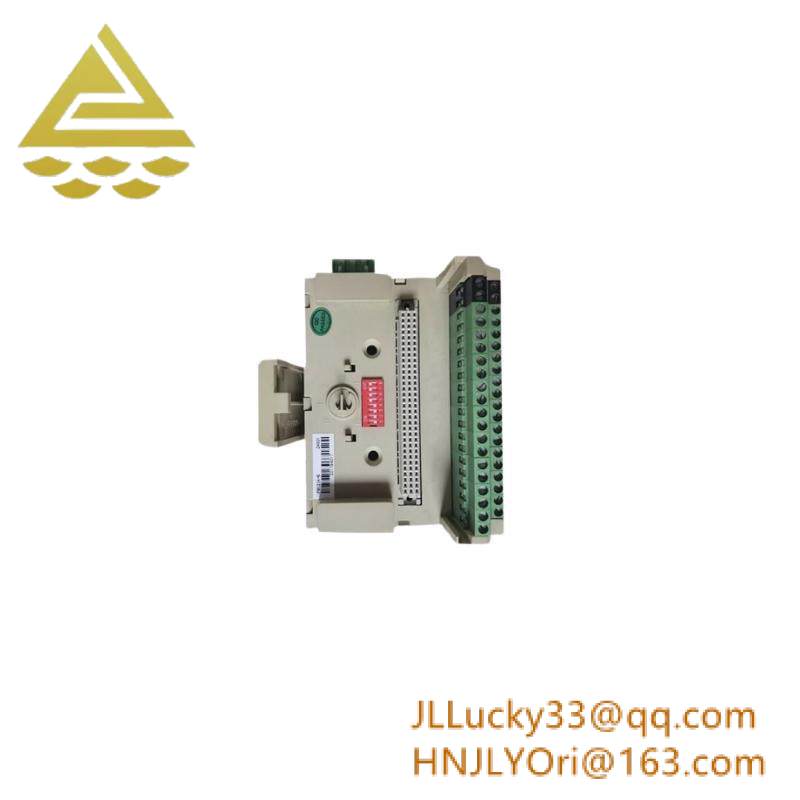

The PF3109GPBHW is an advanced industrial control module engineered for high-precision automation and monitoring tasks in complex industrial environments. As an upgraded variant in the PF3000 series, this module builds on its predecessors’ strengths with enhanced processing capabilities and expanded connectivity options. Its core functionality focuses on real-time data acquisition, processing, and control signal generation, making it an indispensable component in modern industrial control systems.

In automation architectures, the PF3109GPBHW serves as a critical processing hub, bridging field devices and higher-level control systems with exceptional reliability. What sets the PF3109GPBHW apart is its combination of robust performance and flexible configuration, allowing it to adapt to diverse industrial requirements without compromising on accuracy or response time. This versatility makes it a valuable asset for industries where operational precision directly impacts productivity and safety.

Technical Specifications

Key Features and Benefits

The PF3109GPBHW delivers superior processing power through its 32-bit ARM Cortex-M7 processor, enabling complex control algorithms to execute with remarkable speed. This processing capability ensures that even with 16 high-resolution analog inputs and 24 digital I/O channels operating simultaneously, the PF3109GPBHW maintains sub-millisecond response times for critical control functions, a significant improvement over earlier models.

Robustness is a defining characteristic of the PF3109GPBHW. Its isolated analog input channels provide 2.5kV galvanic isolation, protecting sensitive electronics from ground loops and voltage transients common in industrial settings. The extended operating temperature range allows reliable operation in extreme environments, from freezing outdoor enclosures to high-temperature industrial facilities, reducing the need for specialized cooling or heating systems.

Connectivity is a major strength of the PF3109GPBHW, supporting an expanded set of industrial protocols that facilitate seamless integration with both legacy systems and modern smart factory architectures. The module’s redundant power input design eliminates single points of failure, ensuring uninterrupted operation even during power supply disruptions.

Energy efficiency is optimized in the PF3109GPBHW, consuming less than 7W under full load despite its increased functionality. Its modular design simplifies maintenance, while the generous memory capacity supports advanced diagnostics and data logging for predictive maintenance applications.

Application Scenarios

In chemical processing plants, the PF3109GPBHW excels in batch control systems, where it precisely monitors and regulates temperature, pressure, and flow rates across multiple reactors. Its high-resolution analog inputs ensure accurate measurement of critical process variables, while its fast response time enables tight control of chemical reactions, ensuring product consistency and compliance with safety standards.

Within power generation facilities, the PF3109GPBHW is employed in auxiliary systems control, managing boiler feedwater regulation, fuel handling, and emissions monitoring. Its robust design withstands the harsh electrical environments typical in power plants, while its redundant features enhance system reliability—critical for preventing unplanned downtime in energy production.

In advanced manufacturing facilities, the PF3109GPBHW integrates with robotics and vision systems for precision assembly lines. It processes real-time data from position sensors and quality inspection devices, coordinating machinery movements with micron-level accuracy to optimize production yields and reduce waste.

For water and wastewater treatment plants, the PF3109GPBHW manages complex filtration and disinfection processes, balancing multiple variables such as pH levels, chlorine concentration, and flow rates to ensure regulatory compliance and efficient resource utilization.

Related Models

- PF3108GPBHW – Previous model with 8 analog inputs, compatible with PF3109GPBHW configuration tools.

- PF3109GPBSW – Dedicated configuration software for programming and monitoring the PF3109GPBHW.

- PF3110GPBHW – Next-generation model with integrated IoT capabilities, upward compatible with PF3109GPBHW.

- PF3109GPBRD – Redundancy module enabling dual PF3109GPBHW configuration for mission-critical systems.

- PF3009GPBHW – Base model with reduced I/O count, serving as foundation for PF3109GPBHW development.

- PF3109GPBEX – Explosion-proof variant of PF3109GPBHW certified for ATEX Zone 1 hazardous areas.

- PF3109GPBIO – Expansion module adding 8 analog outputs to the PF3109GPBHW system.

- PF3109GPBPS – Enhanced power supply unit optimized for PF3109GPBHW redundant configurations.

Installation and Maintenance

Installation Preparation

Installing the PF3109GPBHW requires a clean, vibration-free environment with adequate ventilation. Ensure the DIN rail has sufficient capacity to support the module’s weight along with adjacent components, maintaining at least 15mm clearance on all sides for airflow. The power supply must be properly grounded, and wiring should follow shielded twisted-pair standards for analog signals to maximize noise immunity. Before power-up, verify that the input voltage matches the PF3109GPBHW‘s specifications and that all communication interfaces are correctly terminated.

Maintenance Recommendations

Regular maintenance for the PF3109GPBHW includes monthly visual inspections to check for connector corrosion or loose terminals, especially in humid environments. The module’s self-diagnostic functions should be reviewed quarterly to identify potential issues before they affect operation. Configuration backups are recommended monthly, stored in multiple locations to prevent data loss. While the PF3109GPBHW is designed for long service life, consider preventive replacement of internal capacitors every 7 years to maintain optimal performance in continuous-operation environments.

Product Warranty

The PF3109GPBHW is backed by a 3-year warranty covering manufacturing defects and component failures under normal operating conditions. This comprehensive coverage includes access to the manufacturer’s global technical support network, providing expert assistance for installation, configuration, and troubleshooting. In the event of a covered issue, the manufacturer offers expedited repair or replacement of the PF3109GPBHW to minimize operational disruption. The warranty also includes free firmware updates during the coverage period, ensuring the PF3109GPBHW remains compatible with evolving system requirements and industry standards, reflecting the manufacturer’s commitment to long-term customer satisfaction.

| ABB | 129765-008 |

| ABB | RET620 2.0 FP1 IEC NBTNAAAANDC6BNN11G |

| ABB | HIEE200130R0002 |

| ABB | DSAI130A+DSTK150 |

| ABB | IPS21-35AD(3BHB017688R0001) |

Leave a comment

Your email address will not be published. Required fields are marked *