Product Overview

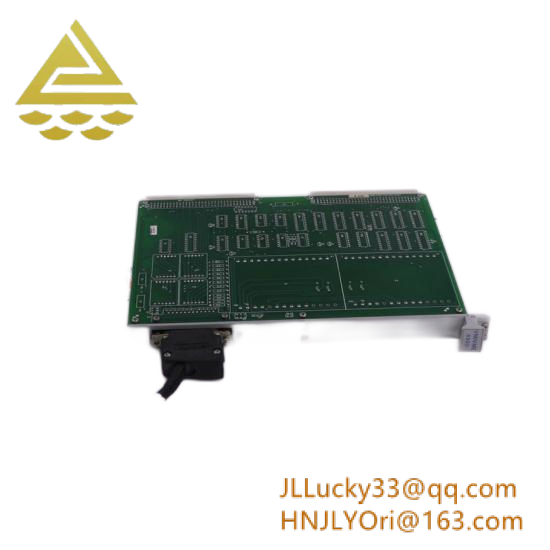

The PF3107 – C – HW is a sophisticated industrial control unit that holds a significant position in modern automation systems. As a key component in process control architectures, it is designed to handle complex control tasks with precision and efficiency. This module serves as a critical link between sensors, actuators, and higher – level control systems, enabling real – time data processing and decision – making in industrial environments.

The PF3107 – C – HW is renowned for its ability to integrate seamlessly into various automation setups, making it a versatile choice for different industrial applications. It excels in regulating and monitoring industrial processes, ensuring that operations run smoothly and within specified parameters. Whether in a small – scale production line or a large – scale industrial plant, the PF3107 – C – HW provides reliable control, contributing to improved productivity and reduced operational costs. Its robust design and advanced functionality make it a valuable asset for industries seeking to enhance their automation capabilities.

Technical Specifications

| Parameter | Value |

| Product Model | PF3107 – C – HW |

| Product Type | Industrial Control Unit |

| Input Voltage | 220 VAC ± 10% |

| Operating Voltage | 24 VDC |

| Power Consumption | ≤ 15 W |

| Operating Temperature Range | 0°C to 60°C |

| Storage Temperature Range | – 20°C to 70°C |

| Protection Class | IP20 |

| Dimensions | 120 mm x 80 mm x 60 mm |

| Communication Interfaces | Ethernet, RS485 |

| Mounting Type | DIN Rail Mounting |

| Weight | Approximately 250 g |

Key Features and Benefits

The PF3107 – C – HW comes with a host of features that make it stand out in the industrial control market. One of its main strengths is its high processing speed, which allows it to handle large amounts of data in real – time. This ensures that industrial processes are controlled with minimal latency, responding quickly to changes in input conditions and maintaining stable operation.

Another notable feature of the PF3107 – C – HW is its extensive connectivity options. With Ethernet and RS485 interfaces, it can easily communicate with a wide range of devices such as sensors, actuators, PLCs, and SCADA systems. This seamless communication capability simplifies the integration of the module into existing automation networks, reducing the time and effort required for system setup.

The module is also designed for durability and long – term reliability. It can operate stably in harsh industrial environments, withstanding temperature variations, electrical noise, and mechanical vibrations. This reliability minimizes the need for frequent maintenance and repairs, ensuring continuous production and reducing downtime. Additionally, its low power consumption helps to lower energy costs, making it an energy – efficient choice for industrial applications.

Application Scenarios

The PF3107 – C – HW is widely used in various industrial sectors. In the water and wastewater treatment industry, it plays a crucial role in controlling and monitoring water treatment processes. It can regulate the operation of pumps, valves, and filtration systems, ensuring that water quality meets the required standards. For example, in a municipal wastewater treatment plant, the PF3107 – C – HW can control the aeration process, adjusting the oxygen levels in the treatment tanks to optimize the biological treatment of wastewater.

In the food and beverage industry, where hygiene and precision are paramount, the PF3107 – C – HW is used to control production lines. It can monitor and adjust parameters such as temperature, pressure, and flow rate, ensuring consistent product quality. In the pharmaceutical industry, it helps to maintain strict process control, adhering to regulatory requirements and ensuring the safety and efficacy of pharmaceutical products.

In the manufacturing of consumer goods, the PF3107 – C – HW is employed to control assembly lines and packaging equipment. It can coordinate the movement of products, control the operation of robots, and monitor the quality of finished goods, improving production efficiency and reducing defects.

Related Models

- PF3107 – A – HW– A basic version of the PF3107 – C – HW with fewer communication interfaces, suitable for simpler control applications.

- PF3107 – D – HW– An upgraded variant of the PF3107 – C – HW with enhanced processing power and additional I/O ports.

- PF3207 – C – HW– A higher – capacity model in the same series as the PF3107 – C – HW, designed for larger – scale industrial control systems.

- PF3106 – C – HW– A previous generation model of the PF3107 – C – HW with similar functionality but slightly lower performance.

- PF4107 – C – HW– A compatible companion module that works with the PF3107 – C – HW to expand I/O capabilities.

- PF3107 – C – SW– The software package specifically designed for the PF3107 – C – HW to enable programming and configuration.

- PF3108 – C – HW– A model with integrated data logging functionality, complementing the control features of the PF3107 – C – HW.

Installation and Maintenance

Installation preparation: Before installing the PF3107 – C – HW, make sure there is adequate space for mounting on a DIN rail. The module has dimensions of 120 mm x 80 mm x 60 mm, so ensure the installation area can accommodate it. A stable power supply of 220 VAC ± 10% is required, along with proper grounding to prevent electrical interference. The installation environment should be within the operating temperature range of 0°C to 60°C and have a protection class of at least IP20 to ensure the module’s longevity.

Maintenance recommendations: Regularly inspect the PF3107 – C – HW for any signs of physical damage or loose connections. Check the power supply voltage to ensure it remains within the specified range. Clean the module’s surface periodically to prevent dust accumulation, which can affect heat dissipation. Perform software diagnostics at regular intervals to detect any potential issues early. If the module shows abnormal behavior or fails to respond, check the communication links and power supply first. In case of irreparable faults, replace the module with a compatible model to maintain system continuity.

Product Warranty

The PF3107 – C – HW is backed by a comprehensive warranty that covers manufacturing defects for a specified period from the date of purchase. During the warranty period, if any issues arise due to faulty materials or workmanship, the manufacturer will repair or replace the module free of charge. The manufacturer also provides global technical support, offering assistance with installation, configuration, and troubleshooting. With a commitment to customer satisfaction, they ensure that customers receive prompt and reliable service whenever needed. This warranty and support package gives customers confidence in the quality and performance of the PF3107 – C – HW, minimizing the risks associated with industrial automation investments.

| ABB | 1TGE120021R0810 |

| ABB | 1TGE120011R2200 |

| ABB | LTC743CE 3BHE013299R0001 |

| ABB | PP245B 3BSC690126R2 |

| ABB | KUC711AE01-GUSP P/N: 3BHB004661R0001 |

| ABB | 3BHL000359P001 |

Leave a comment

Your email address will not be published. Required fields are marked *