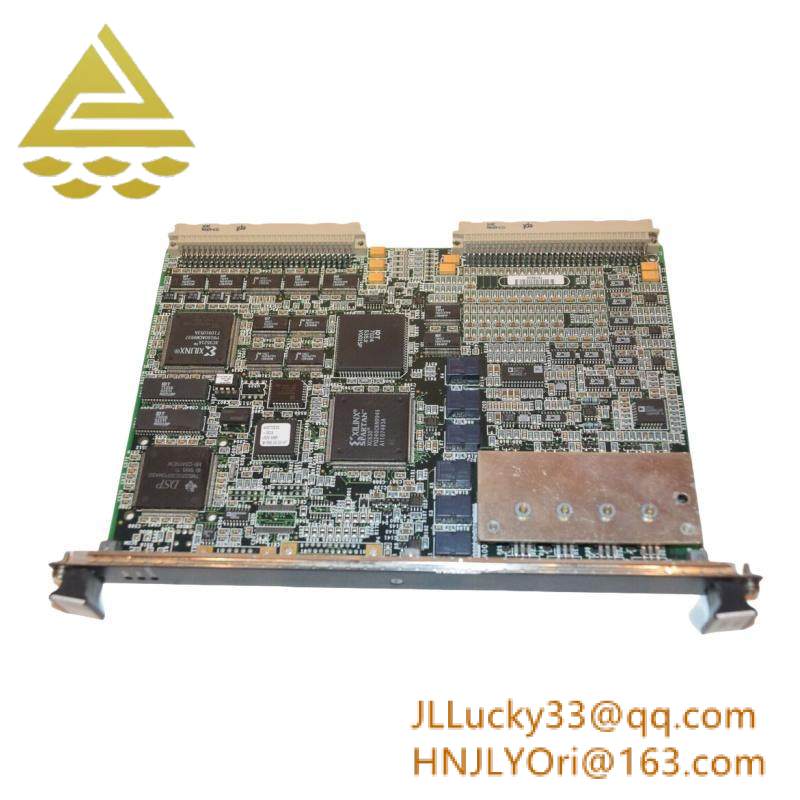

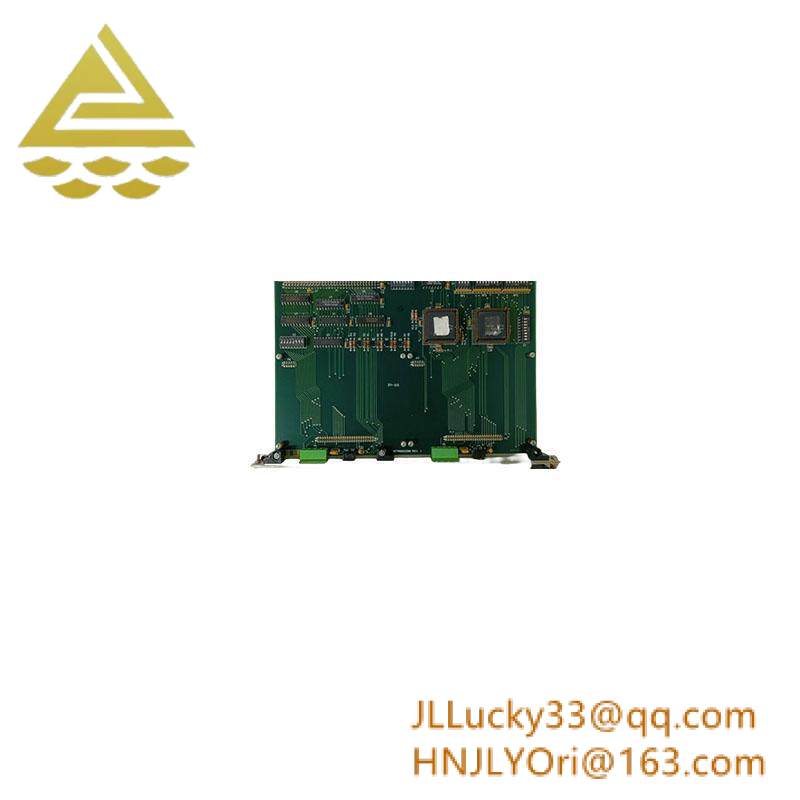

Product Overview

The PF3009-G-HW is a high-performance industrial automation component designed for critical control and monitoring applications across various industrial sectors. As part of a robust control system ecosystem, this module serves as a key interface between field devices and central control systems, facilitating seamless data transmission and precise operation control. Its core functionality centers on processing real-time data from sensors and actuators, enabling accurate decision-making and responsive system adjustments.

In automation setups, the PF3009-G-HW plays a vital role in ensuring operational efficiency and system reliability. It acts as a bridge between different system components, translating and relaying information with minimal latency. What makes the PF3009-G-HW valuable is its ability to operate consistently in demanding industrial environments while maintaining high data integrity, making it a trusted solution for mission-critical applications where downtime is not an option.

Technical Specifications

| Parameter | Value |

| Product Model | PF3009-G-HW |

| Product Type | Industrial Control Module |

| Power Supply | 24 VDC ±10% |

| Dimensions (L x W x H) | 120mm x 80mm x 30mm |

| Communication Protocols | Modbus RTU, Ethernet/IP, Profibus DP |

| Operating Temperature | -20°C to 60°C |

| Mounting Method | DIN rail mountable |

| Protection Level | IP20 (front panel), IP40 (enclosure) |

| Redundancy Support | Optional dual-power input |

| Analog Input Channels | 8 (16-bit resolution) |

| Digital Output Channels | 16 (relay, 2A max per channel) |

| Processor | 32-bit ARM Cortex-M4 |

| Memory | 256KB RAM, 1MB flash storage |

Key Features and Benefits

The PF3009-G-HW delivers exceptional performance through its advanced processing capabilities. Equipped with a 32-bit ARM Cortex-M4 processor, it handles complex data processing tasks with remarkable speed, ensuring real-time responsiveness even when managing multiple input/output signals simultaneously. This processing power translates to faster system reaction times, which is crucial for applications requiring precise timing and coordination.

Reliability is a standout feature of the PF3009-G-HW. Its robust design includes surge protection on all input/output channels, safeguarding against voltage spikes common in industrial environments. The module’s wide operating temperature range allows it to function reliably in both hot industrial facilities and cold outdoor enclosures, eliminating the need for additional environmental control measures.

The PF3009-G-HW excels in connectivity, supporting multiple industry-standard communication protocols. This versatility allows seamless integration with existing control systems, whether upgrading legacy setups or implementing new installations. Its generous memory capacity ensures ample storage for configuration data and temporary logs, facilitating advanced diagnostics and system troubleshooting.

Energy efficiency is another benefit, with the PF3009-G-HW consuming less than 5W under full load, reducing overall power requirements in control cabinets. The module’s compact form factor maximizes space utilization, an important consideration in crowded industrial enclosures.

Application Scenarios

In oil and gas refineries, the PF3009-G-HW finds application in pipeline monitoring systems, where it processes data from pressure and flow sensors to ensure optimal pipeline operation. It enables real-time detection of anomalies, triggering alerts and control actions to prevent leaks or pressure issues that could lead to costly shutdowns.

Within water treatment facilities, the PF3009-G-HW manages chemical dosing systems by monitoring water quality sensors and controlling dosing pumps. Its accurate analog input processing ensures precise chemical addition, maintaining water treatment parameters within required ranges for regulatory compliance.

In manufacturing plants, the PF3009-G-HW integrates with production line machinery, coordinating conveyor systems, robotic arms, and quality inspection devices. It processes data from proximity sensors and vision systems, enabling synchronized operation and immediate adjustment to maintain production efficiency.

Renewable energy facilities, such as solar farms, utilize the PF3009-G-HW to monitor inverter performance and battery storage systems. It collects operational data and communicates with central management systems, helping optimize energy production and storage efficiency.

Related Models

- PF3008-G-HW– Previous generation model with reduced I/O capacity, compatible with PF3009-G-HW programming software.

- PF3009-G-SW– Software package for configuring and monitoring the PF3009-G-HW

- PF3010-G-HW– Enhanced version of PF3009-G-HW with expanded communication options including WirelessHART.

- PF3009-G-RD– Redundant configuration kit for PF3009-G-HW enabling hot-swap capability.

- PF2009-G-HW– Compact variant of PF3009-G-HW with fewer I/O channels for space-constrained applications.

- PF3009-G-EX– Explosion-proof version of PF3009-G-HW certified for hazardous areas (ATEX Zone 2).

- PF3009-G-IO– Expansion module adding 8 analog outputs to the PF3009-G-HW.

Installation and Maintenance

Installation Preparation

Proper installation of the PF3009-G-HW begins with ensuring adequate space on the DIN rail, allowing at least 10mm clearance on both sides for ventilation. The module should be mounted in a control cabinet free from excessive vibration and direct exposure to moisture or corrosive substances. Before powering up, verify that the 24VDC power supply is properly grounded and meets the voltage requirements specified for the PF3009-G-HW. All wiring connections should follow industry standards for industrial control systems, with shielded cables used for analog signals to minimize interference.

Maintenance Recommendations

Routine maintenance for the PF3009-G-HW involves quarterly visual inspections to check for loose connections or signs of overheating. The module’s status indicators should be monitored regularly to ensure all systems are functioning correctly. It is recommended to back up configuration data semi-annually to prevent loss in case of unexpected failures. While the PF3009-G-HW is designed for long service life, consider replacing critical components like input fuses every 5 years as a preventive measure, especially in high-vibration environments.

Product Warranty

The PF3009-G-HW comes with a 2-year warranty covering manufacturing defects and component failures under normal operating conditions. This warranty includes access to technical support from the manufacturer’s global service network, ensuring prompt assistance whenever needed. In the event of a covered issue, the manufacturer provides either repair or replacement of the PF3009-G-HW module, with quick turnaround times to minimize operational disruption. This warranty reflects the manufacturer’s confidence in the PF3009-G-HW‘s quality and commitment to customer satisfaction, backed by comprehensive service offerings including online diagnostics tools and technical documentation.

| ABB | UNITROL 1005 |

| ABB | 3HAC055437-004 |

| ABB | 216EA62 1MRB150083R1/E |

| ABB | 88TK50A-E |

| ABB | SNAT 632 PAC |

Leave a comment

Your email address will not be published. Required fields are marked *