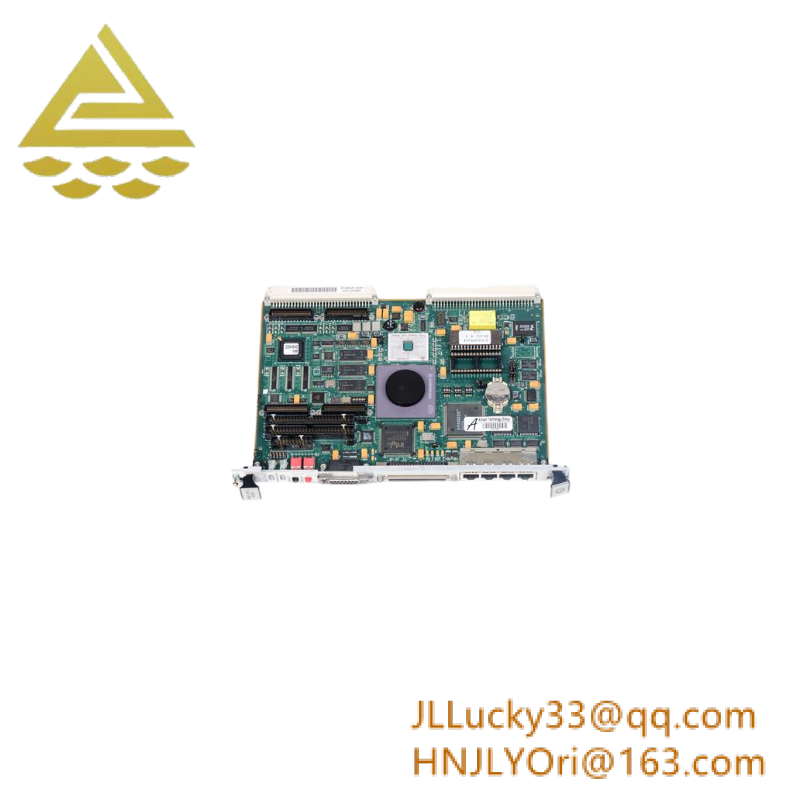

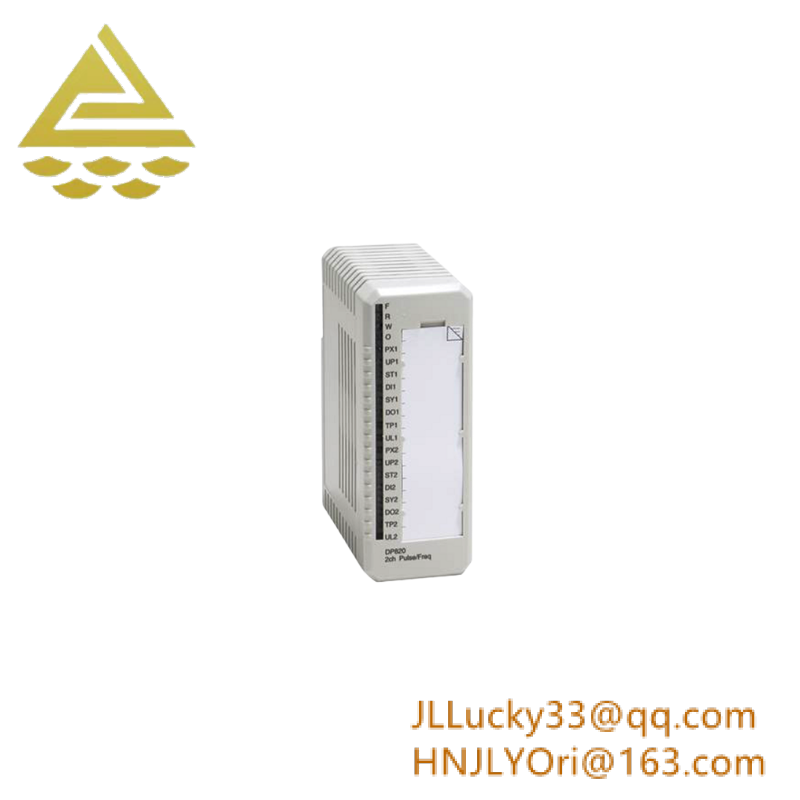

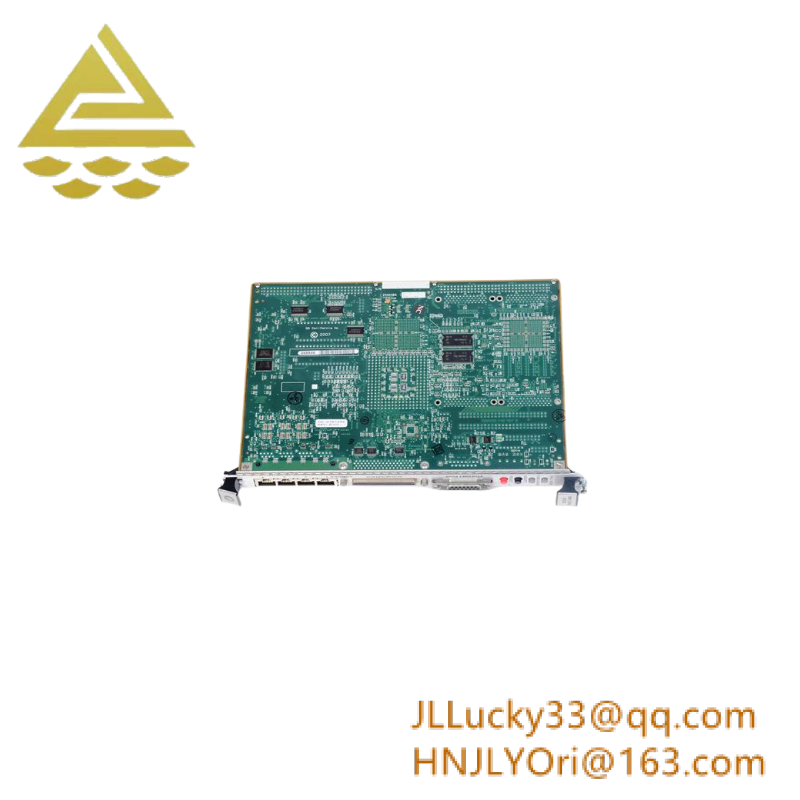

The Allen-Bradley 1756-OB32A is a high-performance digital output module belonging to the ControlLogix family by Rockwell Automation, a cornerstone of industrial automation systems. This module is engineered to deliver reliable control over discrete devices in complex industrial environments, serving as a critical link between the ControlLogix processor and field equipment such as solenoids, relays, and actuators.

As part of the ControlLogix platform, the 1756-OB32A integrates seamlessly with other system components, ensuring consistent communication and coordinated operation across manufacturing lines, process plants, and machinery. Its 32-channel design provides ample capacity for controlling multiple devices, making it suitable for applications ranging from automotive assembly to chemical processing. The 1756-OB32A stands out for its robust construction and advanced diagnostic features, which minimize downtime and enhance system reliability—key factors in maintaining efficient industrial operations. Whether deployed in large-scale facilities or specialized setups, the 1756-OB32A delivers the precision and durability needed to keep critical processes running smoothly.

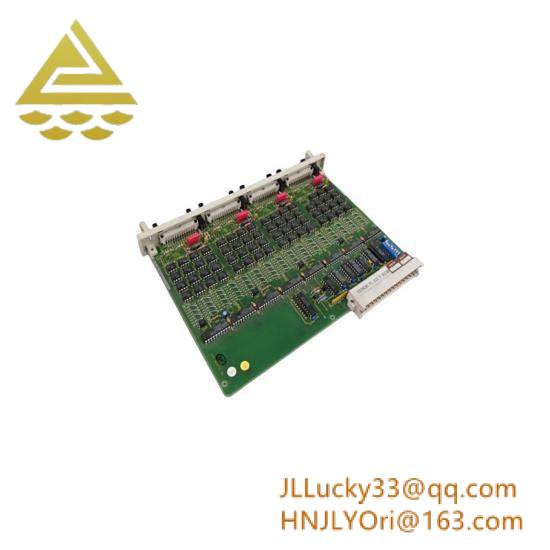

The 1756-OB32A combines high-density control with industrial-grade reliability, making it a standout choice for demanding automation environments. Its 32-channel configuration allows for efficient control of multiple discrete devices within a single module, reducing the need for additional hardware and simplifying system design. Each channel supports 24V DC operation with a maximum current of 0.5A, providing sufficient power to drive a wide range of industrial components without compromising performance.

A key advantage of the 1756-OB32A is its robust isolation capabilities. Channel-to-backplane isolation (250V AC) prevents electrical interference between the module and the rest of the system, ensuring stable operation even in noisy industrial environments. This isolation also enhances safety by protecting sensitive control components from voltage spikes or ground loops.

Diagnostic features are another strength of the 1756-OB32A. The module includes built-in status indicators for each channel, allowing operators to quickly identify issues such as overcurrent or open circuits. This real-time visibility streamlines troubleshooting, reducing downtime and maintenance costs. Additionally, the module integrates with ControlLogix diagnostics software, enabling remote monitoring and alerting—critical for proactive maintenance in large-scale facilities.

Installation and integration are straightforward, thanks to the 1756-OB32A’s compatibility with ControlLogix chassis and processors. Its hot-swappable design allows for replacement without powering down the entire system, further minimizing disruptions. With a wide operating temperature range (0 to 60°C), the module thrives in harsh conditions, from factory floors to outdoor installations, ensuring consistent performance in diverse industrial settings.

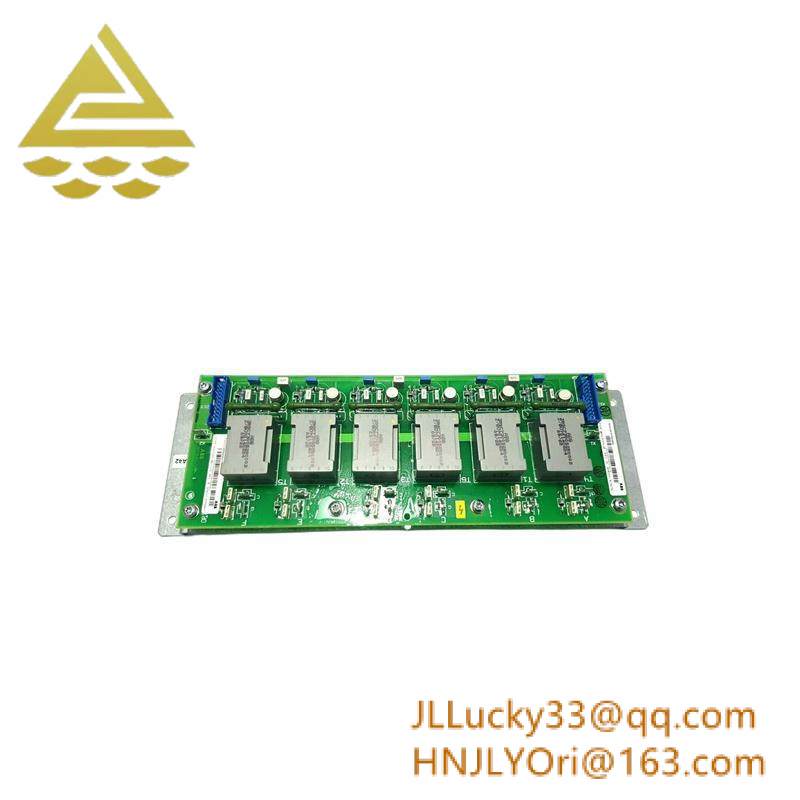

- 1756-OB16D – 16-channel digital output module with higher current capacity (2A per channel), suitable for heavier loads than the 1756-OB32A.

- 1756-IB32 – Complementary 32-channel digital input module, designed to work with the 1756-OB32A for complete I/O integration in ControlLogix systems.

- 1756-OB32E – Enhanced version of the 1756-OB32A with faster response times and improved diagnostic capabilities for time-critical applications.

- 1756-L82E – ControlLogix processor that pairs with the 1756-OB32A to manage output operations in high-performance automation setups.

- 1756-A10 – 10-slot ControlLogix chassis, ideal for housing the 1756-OB32A alongside other I/O modules and processors.

- 1756-OB8 – Compact 8-channel output module, offering a space-saving alternative to the 1756-OB32A for smaller-scale applications.

- 1756-OW16I – AC-output module, providing a different voltage option (120V AC) for systems requiring compatibility with AC devices, alongside the DC-focused 1756-OB32A.

Hainan Jinlin Electromechanical Equipment Co., Ltd, as a trusted distributor of industrial control products, offers the

Allen-Bradley 1756-OB32A with expert support. Our team provides detailed pre-sales guidance to help you integrate the

1756-OB32A into your ControlLogix system, ensuring optimal performance and compatibility. We back every purchase with a one-year after-sales warranty, ensuring peace of mind. If you need assistance or can’t find the model you’re looking for, contact us via WhatsApp [

https://wa.me/+86 19389860630] or email jllucky33@qq.com. We’re dedicated to meeting your industrial automation needs with professionalism and reliability.

Key Features and Benefits

Key Features and Benefits