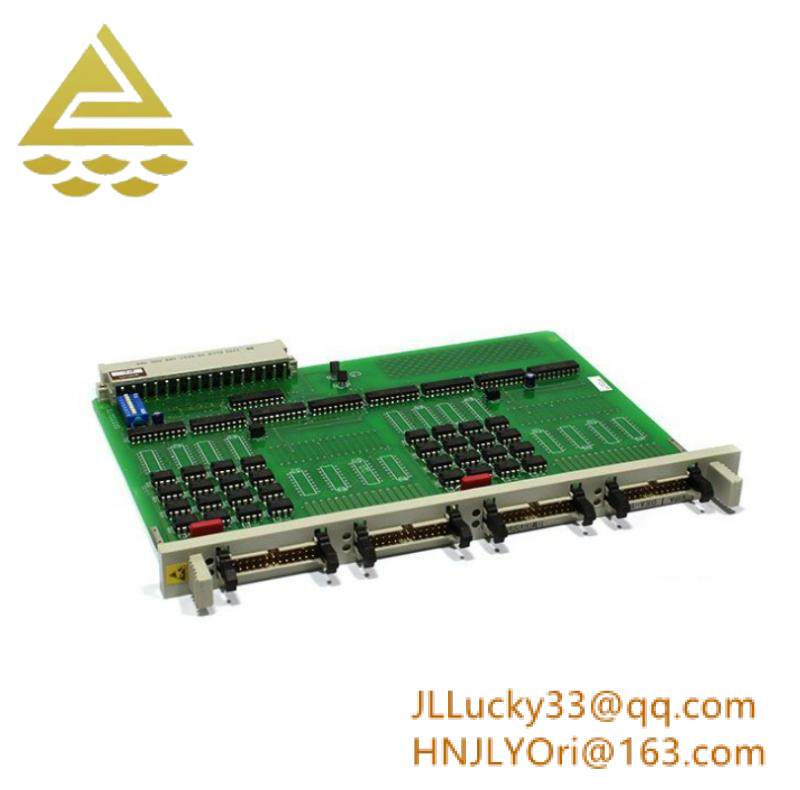

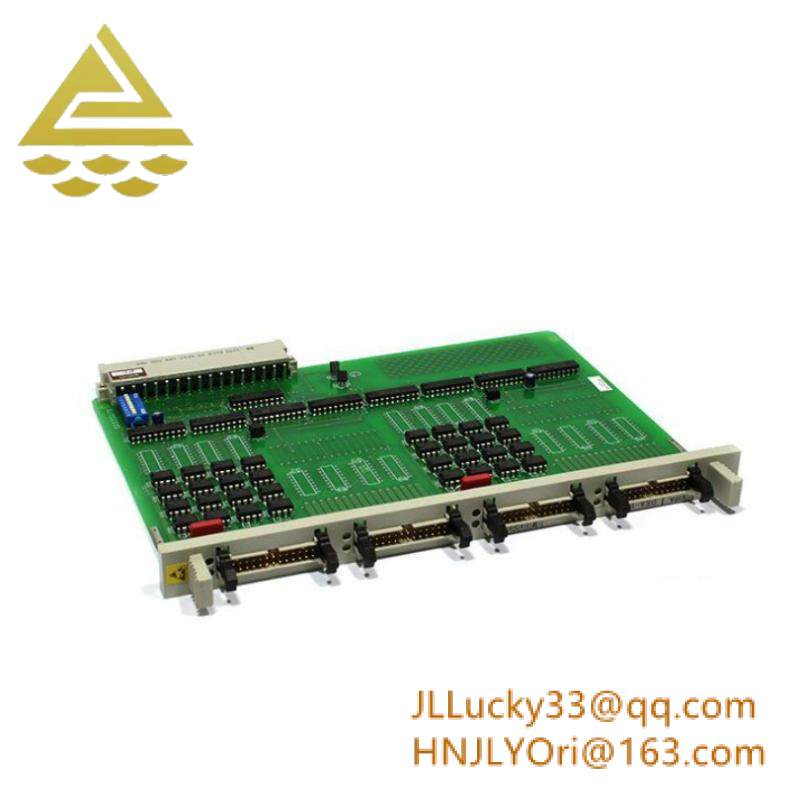

ABB 3BHB024538R0101 | fan assembly (in combination with LT-5165, etc.)

In the field of industrial automation, the efficient operation and precise control of equipment are of vital importance. ABB’s 3BHB024538R0101, in combination with LT-5165 and LT-5165-UL, brings reliable solutions to industrial environments. These products are specifically designed for complex industrial automation systems. Whether it is the manufacturing industry, the energy industry, or various industries that require stable control and efficient signal transmission, they can play a key role.

3BHB024538R0101, as a key component, works in coordination with LT-5165 and LT-5165-UL, aiming to ensure the smooth operation of industrial equipment. For example, in the automated production lines of large factories, they can be used to regulate the operating speed of equipment and ensure the continuity of the production process. In energy production facilities, it can assist in monitoring and managing key links such as power transmission.

Label Specification

Model Number 3BHB024538R0101

Brand ABB

Type fan assembly (in combination with LT-5165, etc.)

Weight: 2.76 kg

Country of Origin: Germany

Warranty 12 months

Shipping DHL / UPS / TNT

Payment: Credit card, PayPal, bank transfer

Availability ETA 13 days

The combination of 3BHB024538R0101, LT-5165 and LT-5165-UL demonstrates outstanding performance. They are elaborately designed with excellent stability and can maintain an efficient state during long-term operation. In industrial environments, challenges such as temperature fluctuations and dust intrusion are often encountered. However, this product portfolio, with its robust construction, can effectively withstand these adverse factors, ensuring the stable operation of the equipment. Its compatibility is also very outstanding, capable of seamless integration with various industrial equipment of different brands and models, facilitating enterprises to build comprehensive automation control systems based on their own needs. For instance, in some complex industrial automation scenarios, this combination can work in coordination with controllers, sensors, etc. of other brands to achieve precise data collection and equipment control.

In industrial production, 3BHB024538R0101, LT-5165 and LT-5165-UL have extensive applications. On the automated assembly lines in manufacturing, they can be used to control the operating rhythm of equipment and ensure the production quality and efficiency of products. By precisely regulating the operating parameters of the equipment, errors in the production process can be reduced and the consistency of the products can be improved. In the energy industry, especially in the power generation and distribution links, they can monitor and adjust the operating status of power equipment in real time, ensure the stability of power supply, reduce the risk of power outages caused by equipment failures, and guarantee the normal electricity supply for industrial production and residents’ lives.

There are still quite a few products related to 3BHB024538R0101, LT-5165 and LT-5165-UL. The 3BHB040342R0001 frequency converter can provide stable and adjustable power supply for equipment, optimize its operational performance, and plays a significant role in scenarios with high requirements for motor speed control. 3BSE0154881 (NAMC-11C), as the drive control unit of ABB ACS600, can precisely regulate and control the drive system. When used in combination with the above-mentioned products, it can further improve the control accuracy and operational efficiency of industrial equipment. The 3BSM037763 series modules perform exceptionally well in power conversion and distribution, and can be used in conjunction with 3BHB024538R0101 and others to improve the architecture of industrial power systems.

When installing 3BHB024538R0101, LT-5165 and LT-5165-UL, the installation manual provided by ABB must be strictly followed. Ensure that the installation location is well-ventilated to avoid affecting the equipment performance due to heat accumulation. At the same time, attention should be paid to the firmness of the installation to prevent loosening during the operation of the equipment. Daily maintenance should not be overlooked either. Regularly check the operating status of the equipment and observe whether there is any abnormal noise or vibration. Check whether the connection lines are loose or damaged, and clean the dust on the surface of the equipment in time to ensure the long-term stable operation of the equipment. If any malfunction of the equipment is found, please contact ABB’s professional technicians for repair in time. Do not disassemble it by yourself to avoid causing more serious damage.

ABB is fully confident in the quality of 3BHB024538R0101, LT-5165 and LT-5165-UL, and offers a global warranty service of up to 12 months. No matter where you are in the world, as long as the product has quality problems during normal use, you can enjoy free repair or replacement services. Meanwhile, ABB has a professional global technical support team that is always ready to answer any questions you may have during the use of the products

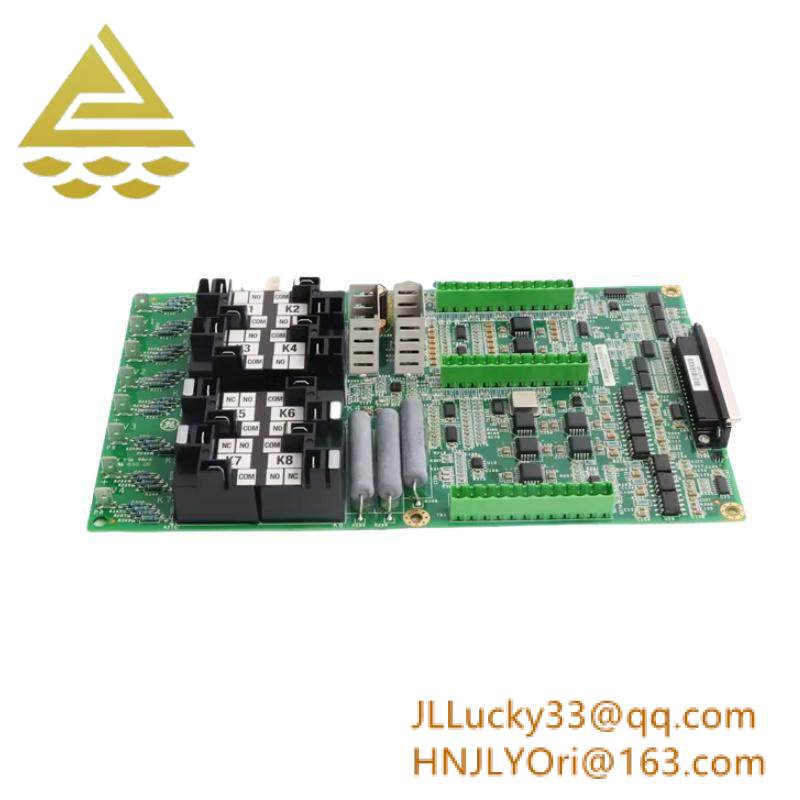

| GE | IC200PWR101D |

| GE | IC3645LXCD1 |

| GE | IC600CB524M |

| GE | IC600CB527M |

| GE | IC660BBA020 |

| GE | IC660BBA104 6231BP10910 |

| GE | IC660BBD022 |

| GE | IC660BBD023 |

| GE | IC660BBD025 |

| GE | IC660EBD020 |