The HIMA H4116 is a high-reliability safety controller

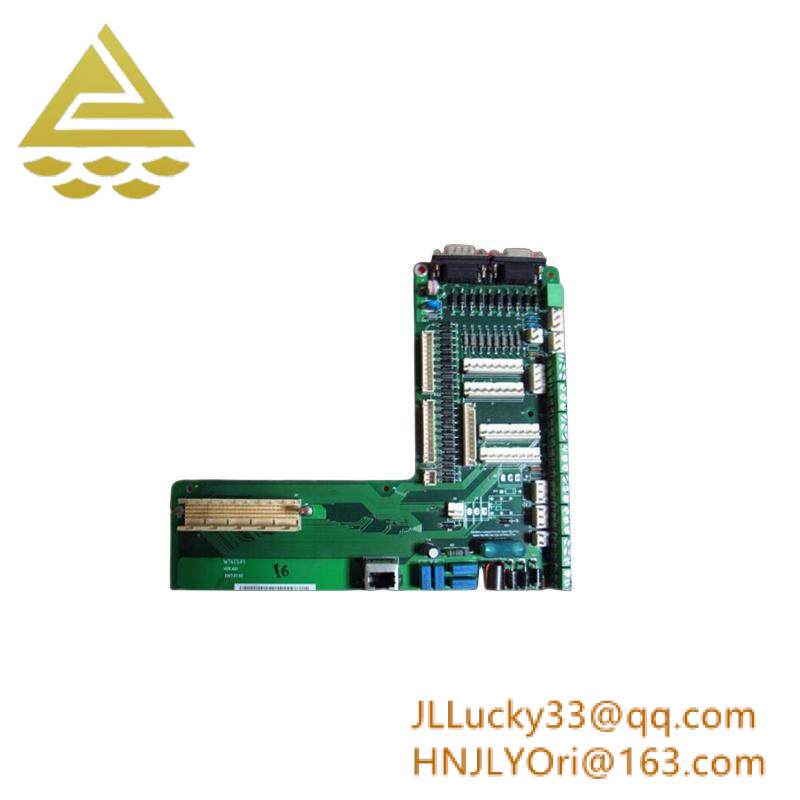

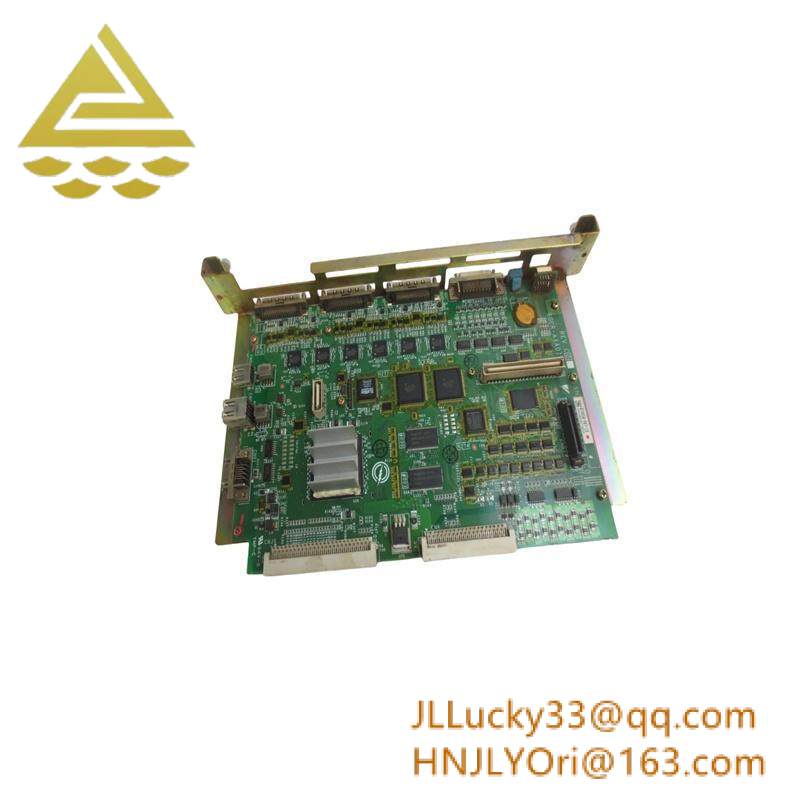

The HIMA H4116 is a high-reliability safety controller designed for critical industrial applications, serving as the core component of safety-instrumented systems (SIS). Part of HIMA’s renowned H41q series, this controller is engineered to meet the most stringent safety requirements in industries where system failures could lead to hazardous outcomes. The HIMA H4116 integrates advanced diagnostics, redundant architecture, and seamless communication capabilities to ensure continuous operation while maintaining safety integrity.

In automation setups, the HIMA H4116 acts as the decision-making unit for safety functions, monitoring process variables and triggering protective actions when anomalies are detected. Its triple modular redundancy (TMR) design and fail-safe mechanisms make it invaluable for applications requiring high availability and fault tolerance. The controller’s compatibility with HIMA’s APROL automation platform enhances system integration, allowing users to manage both process control and safety functions from a unified interface. The HIMA H4116 is trusted in sectors like oil & gas, chemical processing, and power generation for its ability to mitigate risks while optimizing operational efficiency.

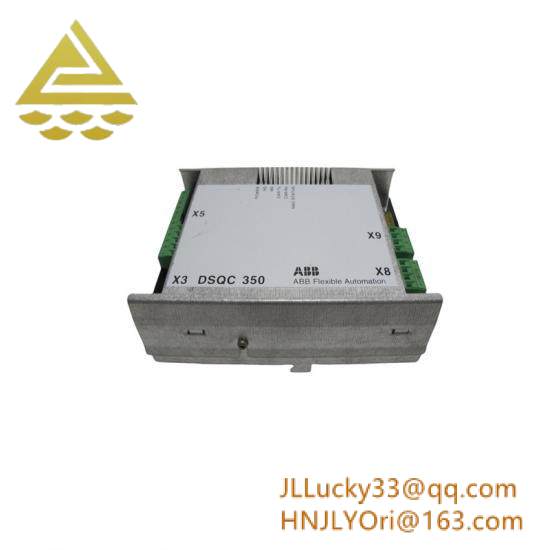

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | HIMA H4116 |

| Manufacturer | HIMA |

| Product Type | Safety Controller |

| Safety Integrity Level | SIL 3 (IEC 61508/61511) |

| Redundancy | Triple Modular Redundancy (TMR) |

| Communication Protocols | PROFIBUS, Ethernet (Modbus, TCP/IP), HIMA Safety Bus |

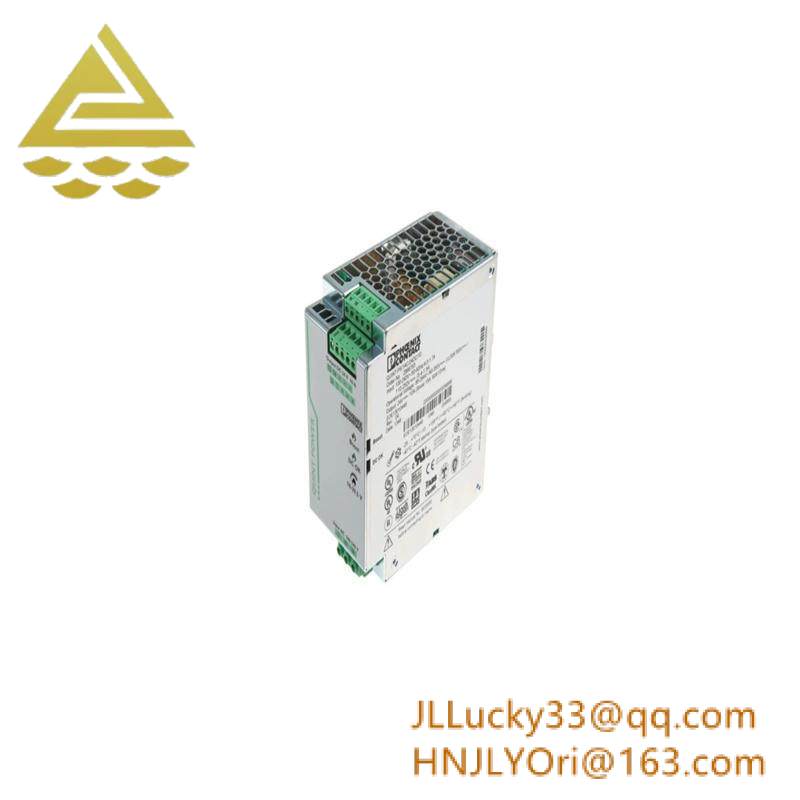

| Power Supply | 24V DC (±15%), redundant power inputs |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Dimensions | 220 mm (H) x 100 mm (W) x 210 mm (D) |

| Mounting Method | DIN rail mounting (35 mm), suitable for 19” control cabinets |

| Protection Class | IP20 (indoor use), certified for harsh industrial environments |

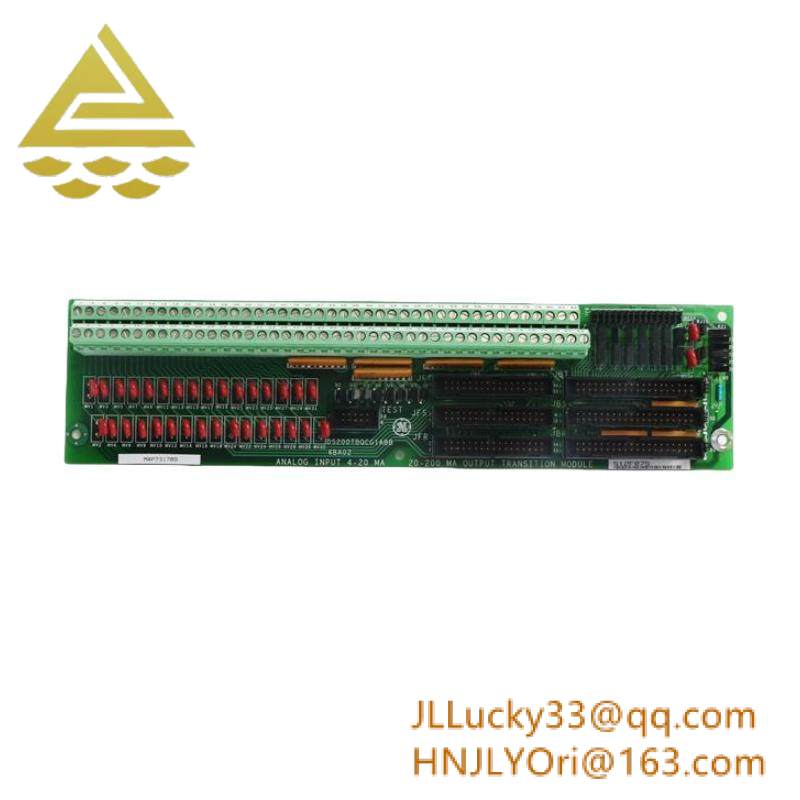

| Process Input/Output | Supports up to 1024 I/O points via expansion modules |

Key Features and Benefits

The HIMA H4116 stands out for its robust safety architecture and operational flexibility. Its TMR design ensures that single-point failures do not compromise system integrity, as each module independently processes inputs and votes on outputs, minimizing the risk of spurious trips or dangerous failures. The controller’s built-in diagnostic coverage exceeds 99%, enabling proactive maintenance by identifying potential issues before they escalate.

Integration capabilities are a core strength of the HIMA H4116. It seamlessly connects with both safety and non-safety systems, allowing users to implement comprehensive safety strategies without disrupting existing infrastructure. The controller supports hot-swappable modules, enabling maintenance or upgrades without shutting down the system—critical for industries where downtime equates to significant losses. Additionally, its compatibility with HIMA’s ELOP II programming language (based on IEC 61131-3) simplifies software development and ensures compliance with international safety standards.

The HIMA H4116 also prioritizes cybersecurity, with features like secure firmware updates and authentication protocols to protect against unauthorized access. Its compact footprint optimizes space in control panels, while rugged construction ensures reliability in harsh environments, including those with high vibration or temperature fluctuations.

Application Scenarios

The HIMA H4116 is ideal for industries where safety is non-negotiable. In oil refineries, it serves as the backbone of emergency shutdown systems (ESD), monitoring pressure, temperature, and flow rates to trigger shutdowns if leaks or overpressures are detected. For chemical plants, the controller manages toxic gas detection systems, activating ventilation or isolation measures to prevent hazardous exposures.

In power generation, the HIMA H4116 protects turbines and generators by enforcing safety interlocks during start-up, operation, and shutdown. It also plays a key role in nuclear facilities, where it ensures compliance with strict safety regulations by controlling reactor protection systems. Additionally, the controller is used in marine applications, such as offshore platforms, where it safeguards against flooding, fire, and mechanical failures in harsh maritime environments.

Manufacturing plants leverage the HIMA H4116 for machine safety systems, preventing operator injuries by monitoring guard positions, emergency stops, and motor parameters. Its ability to interface with programmable logic controllers (PLCs) and distributed control systems (DCS) makes it a versatile choice for retrofitting older infrastructure or implementing new safety-critical projects.

Related Models

- HIMA H51q: An advanced variant of the H41q series with enhanced processing power and expanded I/O capacity, suitable for larger-scale SIS applications.

- HIMA H41q-CPU: The base CPU module for the H41q series, serving as the core processing unit compatible with the HIMA H4116.

- HIMA F3237: A safety I/O module designed to interface with the HIMA H4116, supporting analog and digital signals for process monitoring.

- HIMA F7321: A communication module that enables the HIMA H4116 to connect with higher-level systems via PROFIBUS or Ethernet.

- HIMA H41q-RPS: A redundant power supply unit for the H41q series, ensuring uninterrupted operation for the HIMA H4116.

- HIMA H41q-BUS: A backplane bus system that facilitates communication between modules in the rack, essential for integrating the HIMA H4116 into a complete system.

Installation and Maintenance

Installation Preparation:

Installing the HIMA H4116 requires a controlled environment free from excessive dust, moisture, and electromagnetic interference. The controller mounts on a 35 mm DIN rail within a 19” control cabinet, with sufficient clearance (at least 50 mm) around the module for heat dissipation. Ensure the power supply meets the 24V DC specification with redundant inputs to maintain availability. Grounding must comply with IEC standards to prevent voltage spikes, and all communication cables should be shielded to minimize noise. The controller’s rack should be positioned to allow easy access for programming and maintenance, with clear labeling of connections for quick identification.

Installing the HIMA H4116 requires a controlled environment free from excessive dust, moisture, and electromagnetic interference. The controller mounts on a 35 mm DIN rail within a 19” control cabinet, with sufficient clearance (at least 50 mm) around the module for heat dissipation. Ensure the power supply meets the 24V DC specification with redundant inputs to maintain availability. Grounding must comply with IEC standards to prevent voltage spikes, and all communication cables should be shielded to minimize noise. The controller’s rack should be positioned to allow easy access for programming and maintenance, with clear labeling of connections for quick identification.