Product Overview

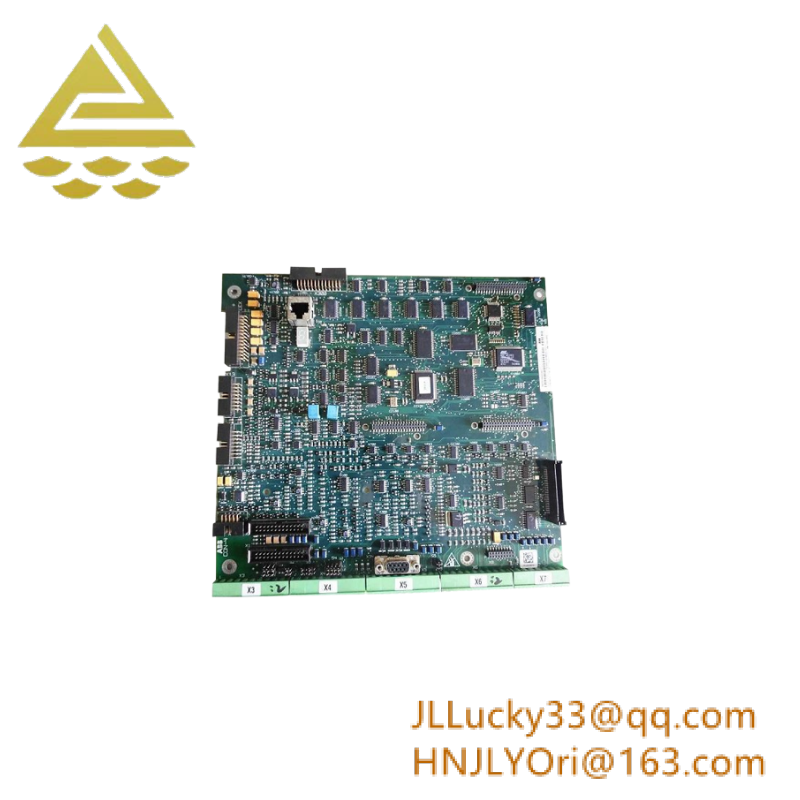

The NXVFD1506A is a high-performance variable frequency drive (VFD) designed to optimize the control of electric motors in various industrial applications. This drive is part of a sophisticated series that enhances energy efficiency and operational flexibility, making it an essential component in modern automation systems. The NXVFD1506A excels in providing precise speed and torque control, which is crucial for applications ranging from pumps and fans to conveyors and compressors.

One of the key functionalities of the NXVFD1506A is its ability to adjust the frequency and voltage supplied to the motor, allowing for smooth acceleration and deceleration. This capability not only improves the overall performance of the motor but also extends its lifespan by reducing mechanical stress. The drive is equipped with advanced features such as built-in protection mechanisms, which safeguard against overloads, short circuits, and overheating, ensuring reliable operation in demanding environments.

The value of the NXVFD1506A lies in its versatility and adaptability. It can be integrated into various automation setups, providing seamless communication with other control systems. This integration capability allows for enhanced monitoring and control, enabling operators to achieve optimal performance and energy savings. Overall, the NXVFD1506A stands out as a robust solution for industries seeking to enhance their motor control systems while minimizing energy consumption and operational costs.

Technical Specifications

| Parameter |

Value |

| Product Model |

NXVFD1506A |

| Manufacturer |

Unknown |

| Product Type |

Variable Frequency Drive |

| Input Voltage |

380-480 V AC |

| Output Voltage |

0-480 V AC |

| Power Rating |

15 kW |

| Frequency Range |

0-60 Hz |

| Control Method |

V/f Control, Vector Control |

| Dimensions |

300 x 200 x 150 mm |

| Weight |

10 kg |

| Protection Class |

IP20 |

| Communication Ports |

RS-485, Ethernet |

Key Features and Benefits

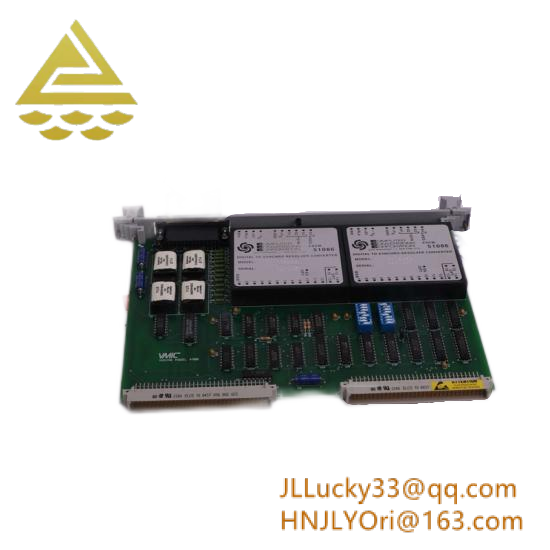

The NXVFD1506A is designed with several key features that enhance its performance and usability in industrial settings. One of its primary advantages is its energy efficiency. By allowing precise control over motor speed, the drive significantly reduces energy consumption, which is particularly beneficial in applications with variable load conditions. This efficiency not only lowers operational costs but also contributes to a more sustainable industrial environment.

Another notable feature of the NXVFD1506A is its advanced control algorithms, which provide superior torque control and dynamic response. This capability is essential for applications requiring quick adjustments to motor speed, such as in material handling or processing industries. The drive’s ability to maintain consistent performance under varying load conditions ensures that operations run smoothly and efficiently.

The NXVFD1506A also includes comprehensive diagnostic and monitoring features. These tools allow operators to track performance metrics and identify potential issues before they escalate, minimizing downtime and maintenance costs. Additionally, the drive’s user-friendly interface simplifies setup and configuration, making it accessible for operators with varying levels of technical expertise.

Overall, the NXVFD1506A stands out for its combination of energy efficiency, advanced control capabilities, and ease of use, making it an ideal choice for a wide range of industrial applications.

Application Scenarios

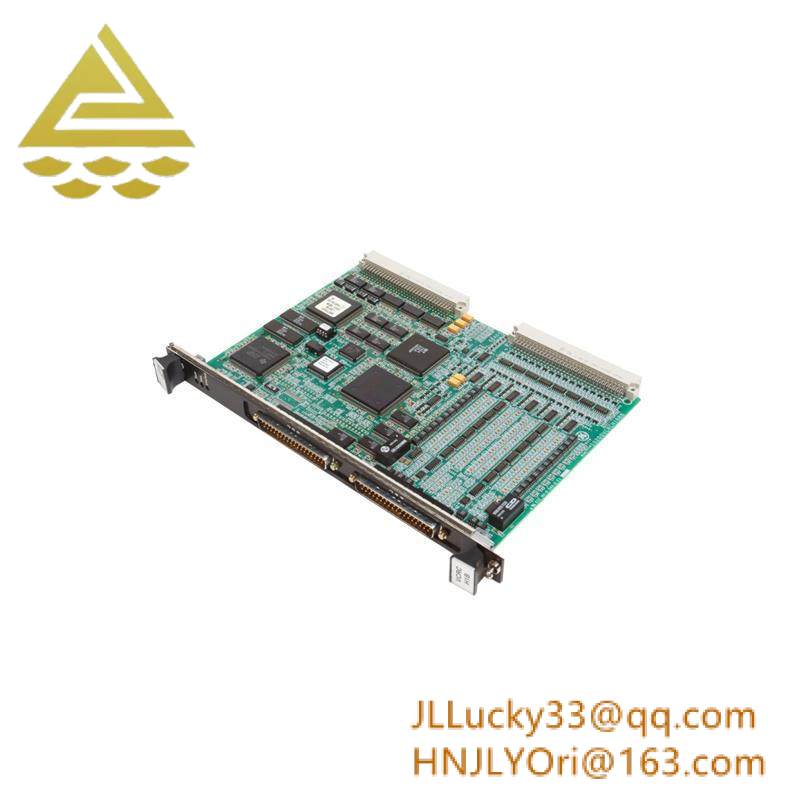

The NXVFD1506A is well-suited for a variety of industrial applications where precise motor control is essential. In the water and wastewater treatment sector, for example, this drive can be used to control pumps, ensuring optimal flow rates while minimizing energy consumption. Its ability to adjust motor speed based on real-time demand helps maintain system efficiency and reliability.

In manufacturing environments, the NXVFD1506A can be employed to drive conveyors and other material handling equipment. By providing smooth acceleration and deceleration, it reduces mechanical wear and enhances the overall lifespan of the equipment. This capability is particularly valuable in high-throughput operations where consistent performance is critical.

The drive is also applicable in HVAC systems, where it can control fans and compressors to optimize energy use while maintaining desired environmental conditions. By adjusting the speed of these components based on real-time requirements, the NXVFD1506A contributes to significant energy savings and improved system performance.

Overall, the NXVFD1506A is a versatile solution that addresses the unique challenges faced by various industries, making it an essential component in modern automation setups.

Related Models

NXVFD1505A – A slightly lower power variant suitable for smaller applications.

NXVFD1507A – An upgraded model with enhanced communication options for advanced integration.

NXVFD1508A – A compact version designed for space-constrained installations.

NXVFD1509A – A model with integrated safety features for critical applications.

NXVFD1510A – A high-efficiency variant optimized for energy savings in continuous operations.

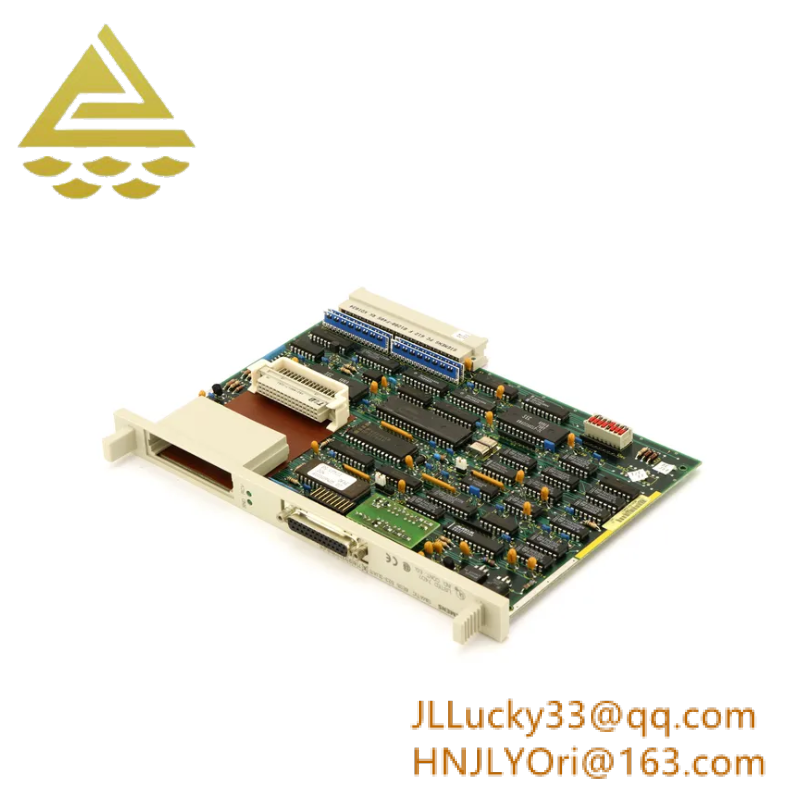

Installation and Maintenance

Installing the NXVFD1506A requires careful planning to ensure optimal performance. It is essential to provide adequate physical space for the drive, allowing for proper airflow and accessibility for maintenance. The installation environment should be free from excessive dust, moisture, and temperature extremes to protect the drive’s components. Proper grounding is also crucial to prevent electrical interference and ensure safe operation.

For maintenance, regular inspections of the NXVFD1506A are recommended to ensure it operates efficiently. Operators should monitor performance metrics and check for any abnormal indicators that may suggest potential issues. It is advisable to keep a maintenance log to track performance and any anomalies observed during operation. Additionally, routine cleaning of the drive’s exterior and ensuring that ventilation pathways are clear will help maintain optimal operating conditions.

By following these installation and maintenance guidelines, users can maximize the lifespan and reliability of the NXVFD1506A, ensuring it continues to deliver exceptional performance in demanding industrial environments.

Product Warranty

The NXVFD1506A is backed by a comprehensive warranty that underscores the manufacturer’s commitment to quality and customer satisfaction. This warranty covers defects in materials and workmanship for a specified period, providing users with confidence in their investment. In addition to warranty coverage, the manufacturer offers global support services, ensuring that assistance is readily available whenever needed. Customers can rely on a network of service professionals to provide timely support and maintenance, further enhancing the value of the NXVFD1506A. With a focus on reliability and performance, the manufacturer stands behind its products, ensuring that users can operate with confidence in their automation solutions.