4-channel analog input module | Delta Tau ACC-34AA

Product Overview

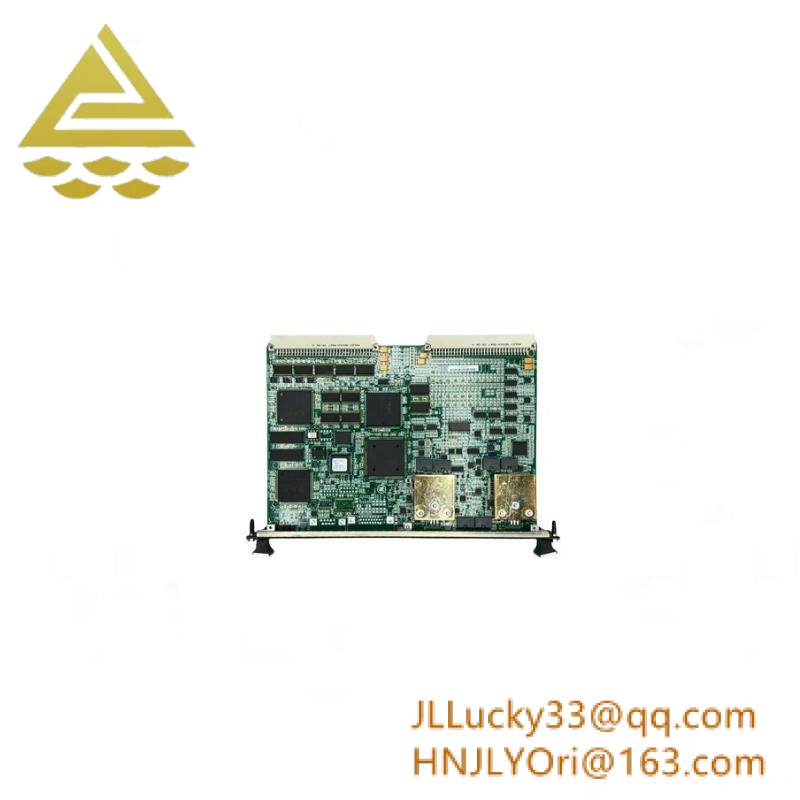

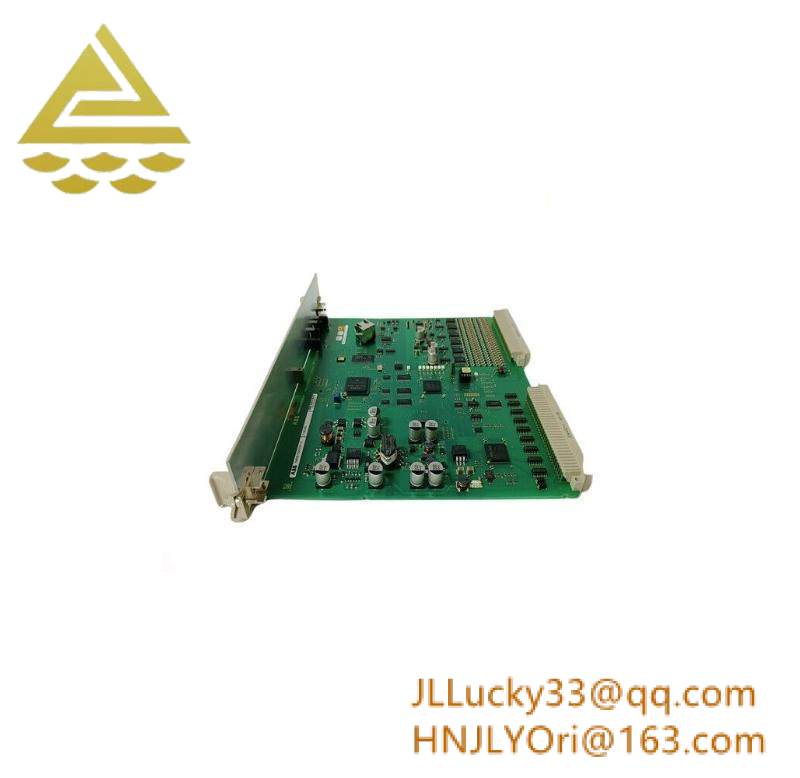

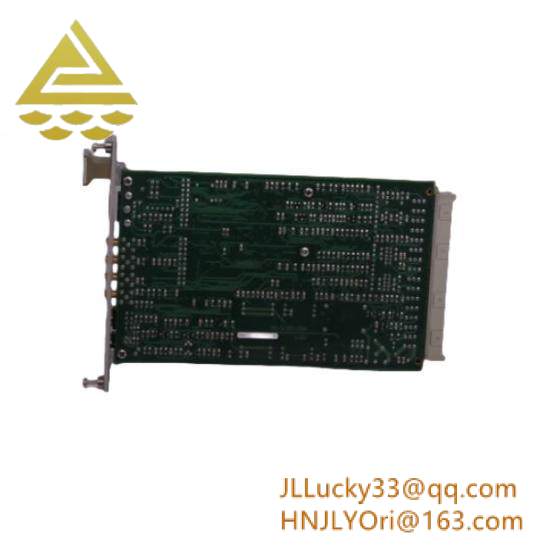

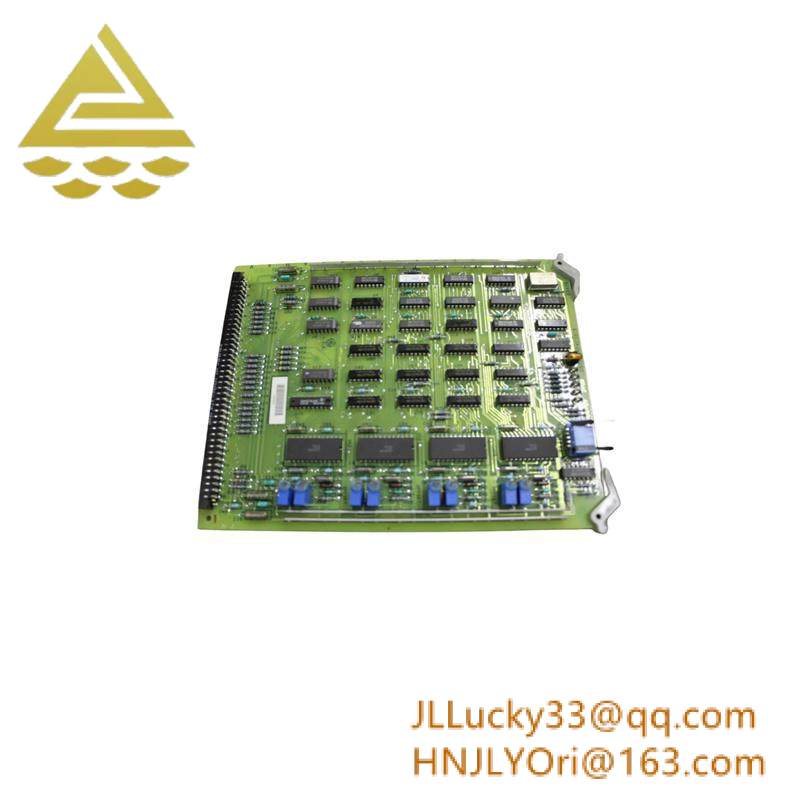

The Delta Tau ACC-34AA is a high-performance 4-channel analog input module designed for precision data acquisition and process monitoring in industrial automation, robotics, and CNC machinery. As part of Delta Tau’s ACC series, renowned for reliability and flexibility, this module integrates seamlessly with Delta Tau’s PMAC (Programmable Multi-Axis Controller) systems, enabling real-time control and diagnostics in complex motion control setups. Its core functionality includes converting analog signals from sensors (e.g., pressure, temperature, or strain gauges) into digital data for analysis and actuation, ensuring accurate process optimization.

The Delta Tau ACC-34AA is a high-performance 4-channel analog input module designed for precision data acquisition and process monitoring in industrial automation, robotics, and CNC machinery. As part of Delta Tau’s ACC series, renowned for reliability and flexibility, this module integrates seamlessly with Delta Tau’s PMAC (Programmable Multi-Axis Controller) systems, enabling real-time control and diagnostics in complex motion control setups. Its core functionality includes converting analog signals from sensors (e.g., pressure, temperature, or strain gauges) into digital data for analysis and actuation, ensuring accurate process optimization.

Key to the ACC-34AA is its 16-bit resolution ADC, which delivers exceptional signal fidelity (±0.015% linearity) across configurable input ranges of ±10V, ±5V, or ±2.5V. The module supports differential inputs to minimize noise interference, making it ideal for high-noise environments like factory floors or motor-driven systems. Its compatibility with EtherCAT and CANopen protocols allows seamless integration with modern automation architectures, while the 24V DC isolated power supply ensures stable operation in harsh industrial conditions.

For industries requiring high-speed data processing, the ACC-34AA offers simultaneous sampling at 200kS/s per channel, enabling real-time monitoring of dynamic processes such as vibration analysis or rapid temperature fluctuations. Its compact design (100mm x 120mm x 50mm) and DIN rail mounting simplify installation in control cabinets, while the rugged IP20-rated housing protects against dust and accidental contact.

Hainan Jinlin Electromechanical Equipment Co., Ltd., as a certified Delta Tau partner, provides end-to-end support for the ACC-34AA, including pre-sales system compatibility assessments and post-sales technical assistance backed by a one-year warranty. Our team of experts ensures seamless integration with PMAC controllers, offering parameter tuning and diagnostic tools to maximize system performance.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | ACC-34AA |

| Manufacturer | Delta Tau |

| Product Type | 4-Channel Analog Input Module |

| Input Range | ±10V, ±5V, ±2.5V (software-configurable) |

| Resolution | 16-bit (±0.015% linearity) |

| Sampling Rate | 200kS/s per channel (simultaneous) |

| Communication Protocols | EtherCAT, CANopen, Delta Tau PMAC Bus |

| Power Supply | 24V DC (±10% tolerance, isolated) |

| Protection Class | IP20 (dust-protected) |

| Mounting Type | DIN Rail (35mm standard) |

| Dimensions (LxWxH) | 100mm x 120mm x 50mm |

Key Features and Benefits

-

High-Precision Data Acquisition

The ACC-34AA’s 16-bit ADC and differential inputs ensure accurate signal conversion, critical for applications like aerospace testing or semiconductor wafer inspection. Its auto-zero calibration feature eliminates offset errors, maintaining long-term measurement stability . -

Flexible Configuration

Users can dynamically adjust input ranges and sampling rates via Delta Tau’s PMAC Software Development Kit (SDK), allowing the module to adapt to diverse sensor types without hardware modifications. This flexibility reduces inventory costs by supporting multiple applications with a single module. -

Real-Time Integration

With EtherCAT compatibility, the ACC-34AA achieves sub-microsecond latency, enabling synchronized data exchange with Delta Tau’s PMAC controllers for closed-loop motion control. This is vital for applications like collaborative robotics, where split-second responsiveness is essential. -

Rugged Industrial Design

The module’s isolated power supply and galvanic isolation between channels protect against voltage spikes and electromagnetic interference (EMI), ensuring reliable operation in environments with high electrical noise . -

Ease of Maintenance

The ACC-34AA features hot-swappable connectors, allowing field replacement without powering down the entire system. Hainan Jinlin Electromechanical provides remote diagnostics via PMAC’s built-in tools, minimizing downtime during troubleshooting.

Our team also offers custom cable assemblies and firmware updates to optimize the ACC-34AA for unique requirements, such as integrating with third-party SCADA systems or legacy PLCs.

Related Models

- Delta Tau ACC-32AA – 2-channel analog input module, suitable for cost-sensitive or space-constrained applications.

- Delta Tau ACC-44AA – 4-channel analog output module, paired with the ACC-34AA for full I/O control in closed-loop systems.

- Delta Tau PMAC2-PC104 – Compact motion controller compatible with the ACC-34AA for standalone CNC machine retrofits.

- Delta Tau ACC-34DA – 4-channel analog input/output hybrid module, ideal for applications requiring both sensing and actuation.

- Delta Tau ACC-34AI – Variant with isolated inputs, designed for high-voltage environments (e.g., power generation).

- Delta Tau ACC-34E – EtherCAT-only version with enhanced network redundancy for mission-critical systems.

Contact Information

For customized solutions or assistance, contact Hainan Jinlin Electromechanical:

For customized solutions or assistance, contact Hainan Jinlin Electromechanical:

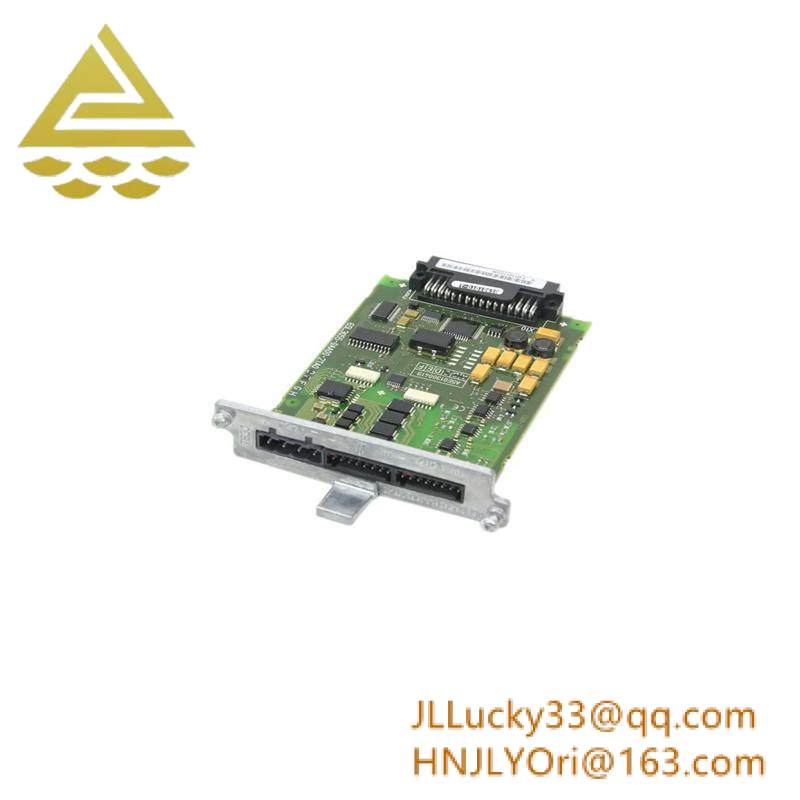

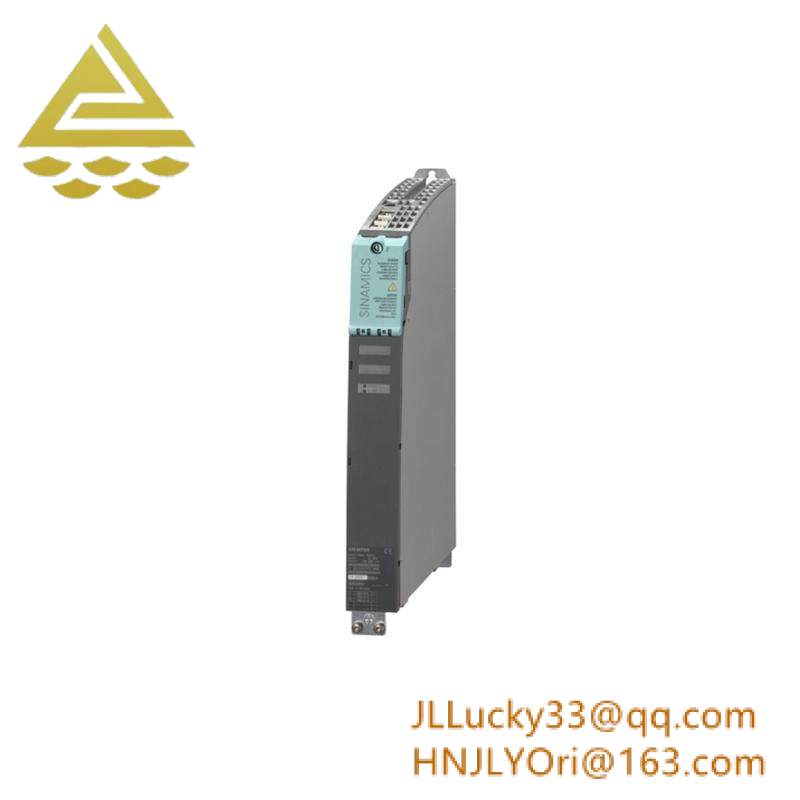

trusted platform for precision automation, the ACC-36E serves as a critical interface between motion controllers (e.g., DELTA TAU’s Clipper series) and distributed I/O devices, drives, and sensors. Its core function lies in enabling seamless, low-latency communication (≤1 ms cycle time) across EtherCAT networks, supporting up to 64 slave devices for complex multi-axis synchronization in applications like CNC machining, robotics, and semiconductor wafer handling.

trusted platform for precision automation, the ACC-36E serves as a critical interface between motion controllers (e.g., DELTA TAU’s Clipper series) and distributed I/O devices, drives, and sensors. Its core function lies in enabling seamless, low-latency communication (≤1 ms cycle time) across EtherCAT networks, supporting up to 64 slave devices for complex multi-axis synchronization in applications like CNC machining, robotics, and semiconductor wafer handling.