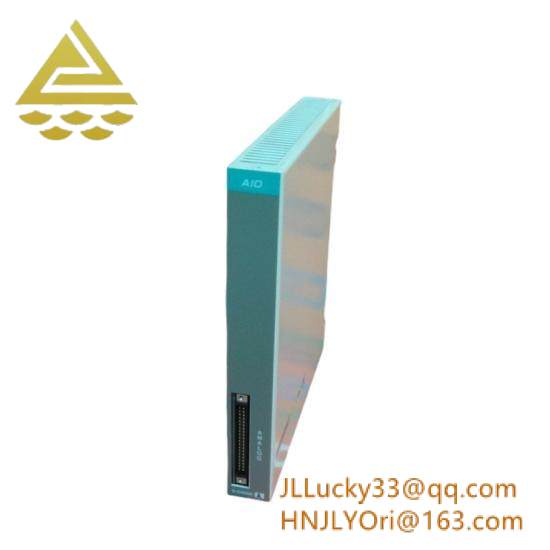

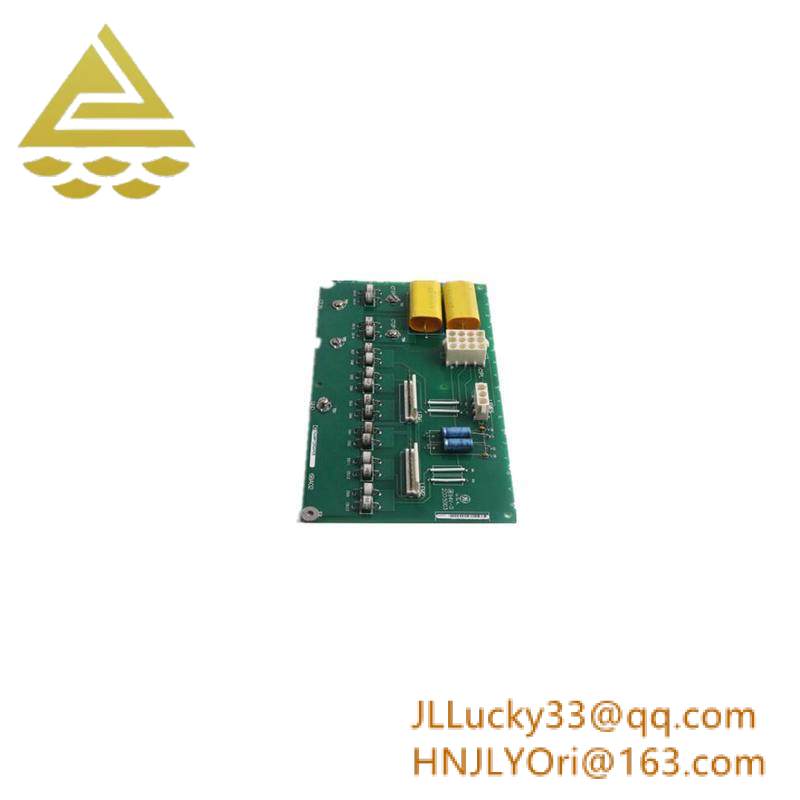

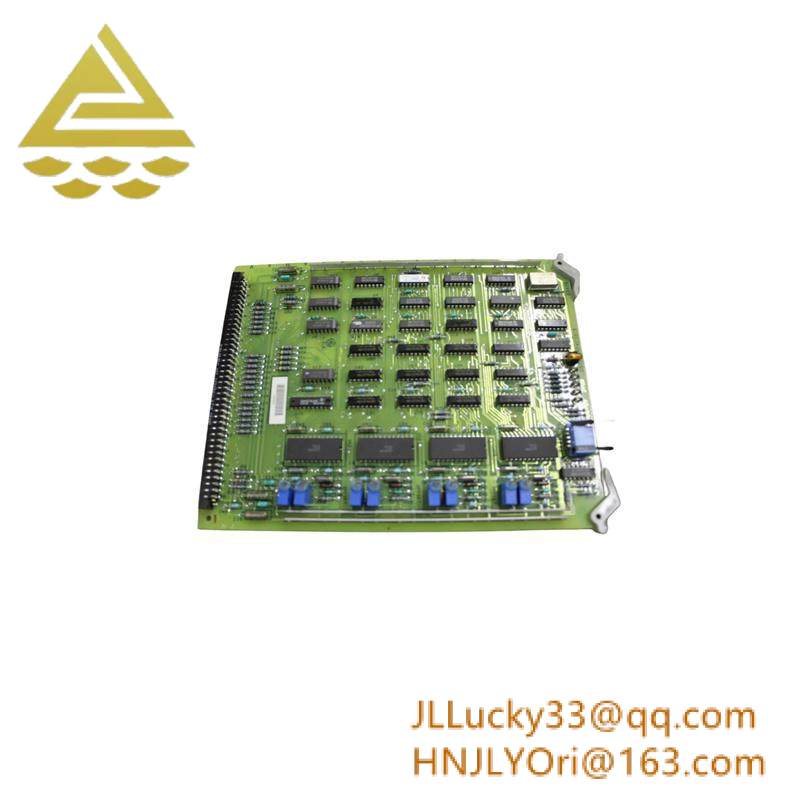

Digital Microprocessor Controller | Woodward 9907-164

Product Overview

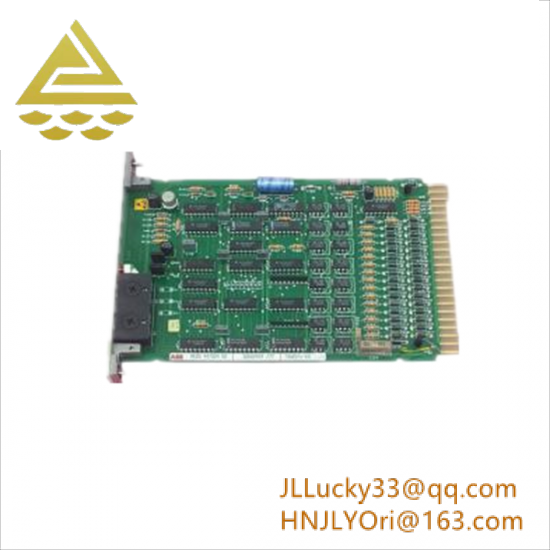

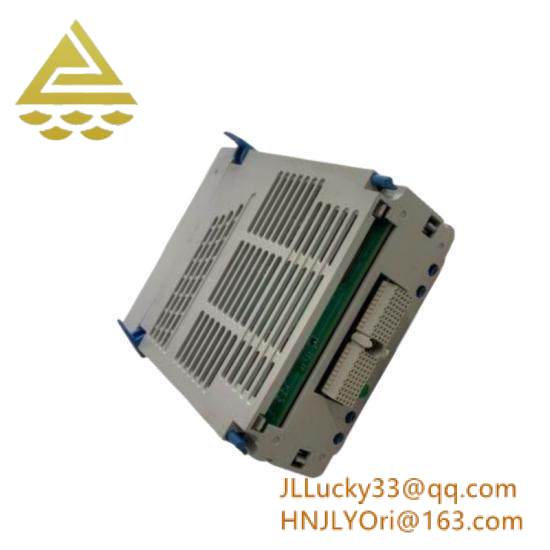

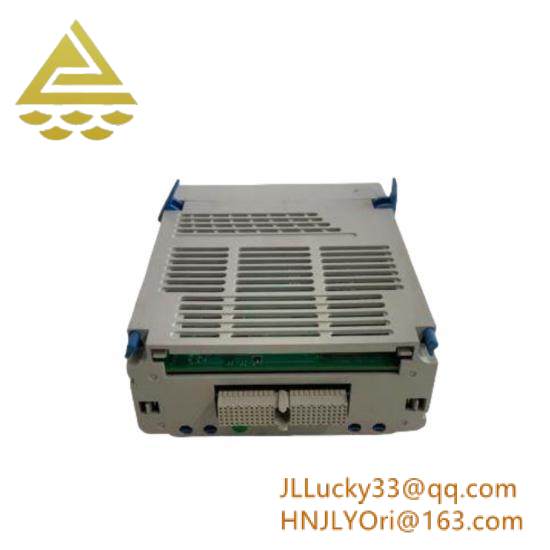

The Woodward 9907-164 is a digital microprocessor controller module engineered for precision speed regulation in industrial turbines and rotating machinery. As part of Woodward’s specialized control lineup23, it delivers real-time processing capabilities to stabilize equipment performance under volatile conditions like extreme vibration and temperature fluctuations1. Serving as a core component in automation systems, this module integrates seamlessly with governors and actuators, enabling dynamic adjustments to rotational speed for enhanced operational safety and efficiency23. Its flexibility allows on-site configuration by operators, making the Woodward 9907-164 indispensable for power generation, marine propulsion, and heavy industrial applications where reliability is non-negotiable23.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | Woodward 9907-164 |

| Manufacturer | Woodward |

| Product Type | Digital Microprocessor Controller |

| Key Function | Speed Regulation & Turbine Control |

| Compatibility | 505 Governor Series |

| Configuration | Field-Programmable |

| Environmental | Vibration/Temperature Resistant |

Key Features and Benefits

1. Robust Industrial Design

Engineered to withstand harsh operating conditions, including significant mechanical vibration and wide temperature ranges, ensuring longevity in demanding environments like power plants and marine systems15.

2. Operational Flexibility

Features extensive field configurability, allowing operators to adapt control parameters on-site without system downtime. This adaptability supports integration with legacy and modern Woodward governors23.

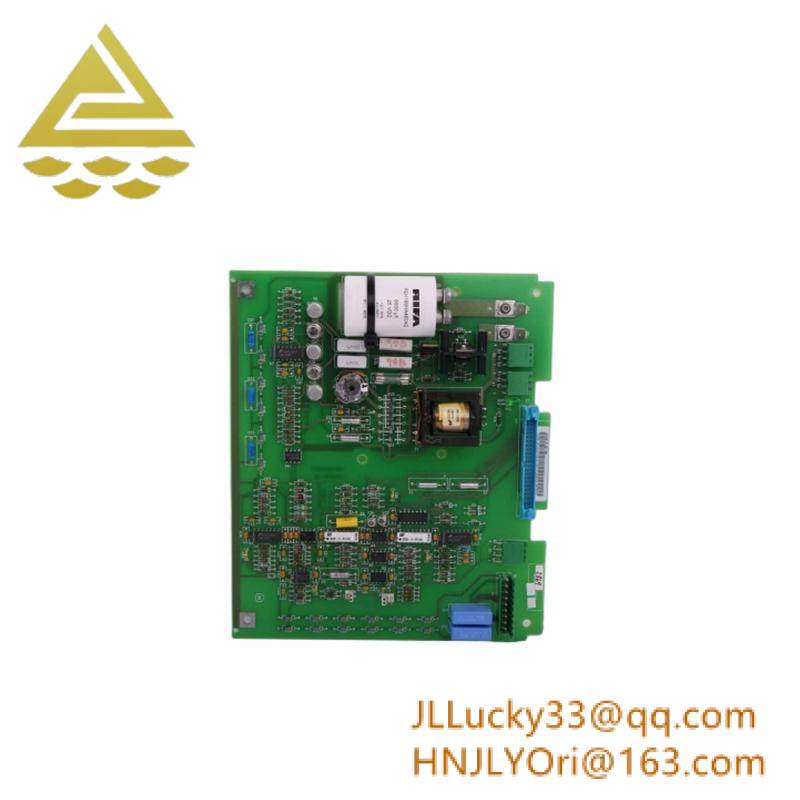

3. Precision Speed Control

Utilizes advanced microprocessor algorithms to maintain ±0.02% speed accuracy, critical for preventing turbine overspeed and mechanical stress in generators and compressors23.

4. Diagnostic Capabilities

Embedded self-monitoring functions provide real-time fault detection and historical event logging, simplifying root-cause analysis during maintenance cycles3.

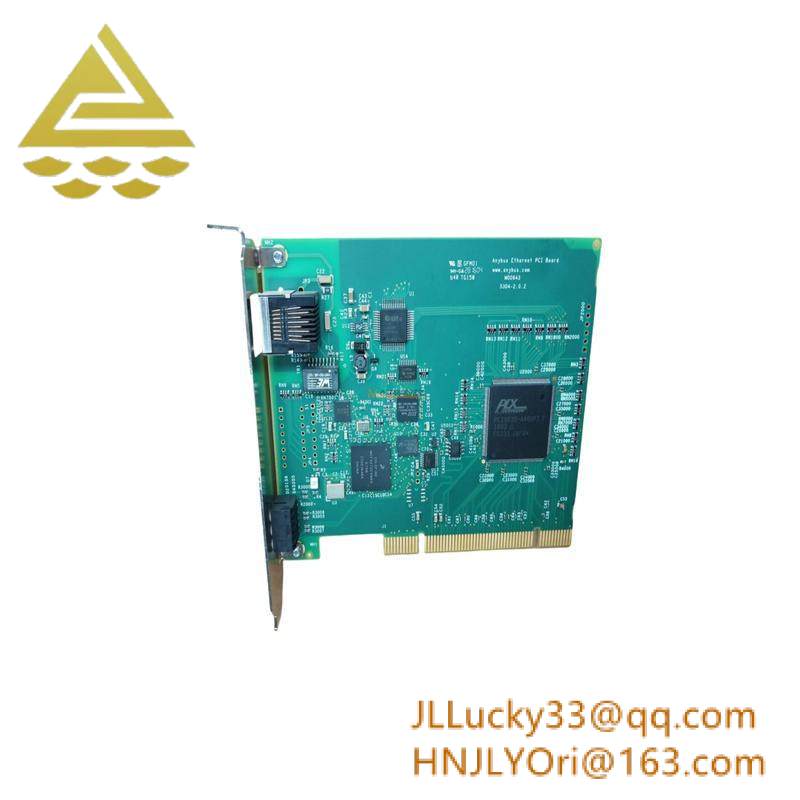

5. Seamless Integration

Direct compatibility with Woodward’s 505 series governors and third-party I/O systems, enabling plug-and-play deployment in multi-vendor automation architectures25.

Related Models

- 9907-1200: Signal converter for hybrid control systems5

- 5466-258: Redundant controller for critical turbine applications4

- 505XT: Next-gen digital governor with enhanced HMI3

Why Choose Us?

Hainan Jinlin Electromechanical ensures 100% authentic Woodward 9907-164 modules, backed by 1-year warranties and 24/7 technical support. Contact us via WhatsApp or email jllucky33@qq.com for expedited global shipping.

| woodward | 8516-051 |

| woodward | 9907-163 |

| woodward | 9907-166 |

| woodward | 9907-173 |

| woodward | 9907-175 |

| woodward | 9907-186 |

Key Features and Benefits

Key Features and Benefits