Product Overview

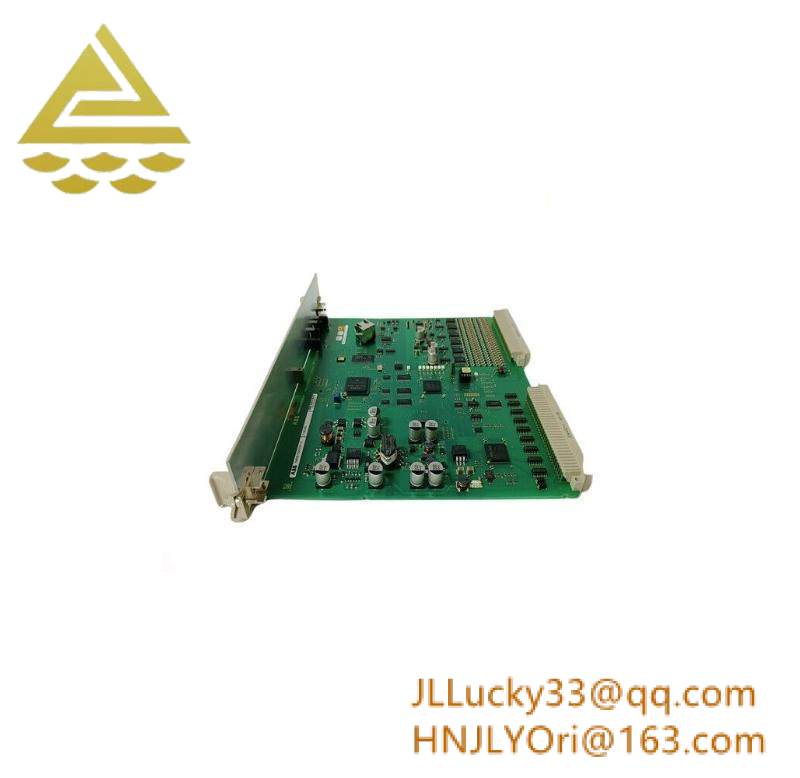

The DELTA TAU CLIPPER 603926-101 is a high-performance multi-axis motion controller designed for precision automation in demanding industrial environments. As part of DELTA TAU’s CLIPPER series, a benchmark in motion control technology, the CLIPPER 603926-101 excels in real-time synchronization, multi-axis coordination, and seamless integration with CNC systems, robotics, and semiconductor manufacturing equipment. Its core function lies in translating complex motion profiles into precise machine movements, supporting applications ranging from high-speed robotic assembly lines to advanced CNC machining centers. With native support for EtherCAT (version 1.1) and CANopen (CiA 402 profile), the CLIPPER 603926-101 ensures low-latency communication with drives, sensors, and HMIs, making it ideal for industries requiring sub-millisecond response times.

The DELTA TAU CLIPPER 603926-101 is a high-performance multi-axis motion controller designed for precision automation in demanding industrial environments. As part of DELTA TAU’s CLIPPER series, a benchmark in motion control technology, the CLIPPER 603926-101 excels in real-time synchronization, multi-axis coordination, and seamless integration with CNC systems, robotics, and semiconductor manufacturing equipment. Its core function lies in translating complex motion profiles into precise machine movements, supporting applications ranging from high-speed robotic assembly lines to advanced CNC machining centers. With native support for EtherCAT (version 1.1) and CANopen (CiA 402 profile), the CLIPPER 603926-101 ensures low-latency communication with drives, sensors, and HMIs, making it ideal for industries requiring sub-millisecond response times.

What distinguishes the CLIPPER 603926-101 is its ruggedized design and compatibility with DELTA TAU’s PMAC (Programmable Multi-Axis Controller) software suite, which enables intuitive programming for trajectory planning, error compensation, and diagnostic monitoring. Whether deployed in automotive manufacturing for robotic welding or in semiconductor fabs for wafer inspection systems, the CLIPPER 603926-101 delivers uncompromising reliability and scalability. Hainan Jinlin Electromechanical, as a certified distributor, provides end-to-end support for integrating this controller into custom automation setups, ensuring compliance with industry standards like CE and UL.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | DELTA TAU CLIPPER 603926-101 |

| Manufacturer | DELTA TAU |

| Product Type | Multi-Axis Motion Controller |

| Power Input | 24V DC (±10% tolerance) |

| Communication Protocols | EtherCAT (v1.1), CANopen (CiA 402) |

| Control Cycle Time | ≤1 ms |

| Operating Temperature | -20°C to 60°C |

| Dimensions | 120mm (L) x 80mm (W) x 30mm (H) |

| Protection Rating | IP20 (dust-protected) |

Key Features and Benefits

The CLIPPER 603926-101 combines cutting-edge hardware with versatile software tools to address the most complex motion control challenges:

The CLIPPER 603926-101 combines cutting-edge hardware with versatile software tools to address the most complex motion control challenges:

- Multi-Axis Synchronization: Supports up to 4 axes of simultaneous control, enabling intricate interpolated movements (e.g., circular, helical, or gantry configurations) with nanometer-level precision.

- Real-Time Diagnostics: Built-in LED indicators and PMAC software alerts provide instant visibility into controller health, motor status, and communication integrity, reducing downtime by up to 30%.

- Programming Flexibility: Compatible with PLCopen Motion standard and DELTA TAU’s proprietary scripting language, allowing engineers to customize motion logic without compromising performance.

- Rugged Reliability: Industrial-grade components ensure stable operation in high-vibration environments, while wide temperature tolerance (-20°C to 60°C) makes it suitable for extreme factory conditions.

Hainan Jinlin Electromechanical’s pre-sales team offers tailored system design consultations, ensuring the CLIPPER 603926-101 integrates seamlessly with your existing infrastructure. Post-installation, our technical experts provide 24/7 support, backed by a one-year warranty, to optimize performance and troubleshoot issues. This controller’s combination of speed, accuracy, and ease of use makes it a cost-effective solution for upgrading legacy systems or building next-gen automation lines.

Related Models

DELTA TAU CLIPPER 603926-201 – Enhanced variant with dual-core processing and expanded memory for multi-tasking in large-scale robotic systems.

DELTA TAU CLIPPER 603926-001 – Entry-level model with basic 2-axis control, ideal for simple conveyor systems or test benches.

DELTA TAU CLIPPER 603926-301 – Redundant controller for fail-safe applications, ensuring uninterrupted operation in pharmaceutical or aerospace manufacturing.

DELTA TAU CLIPPER 603926-401 – Compact version of CLIPPER 603926-101, optimized for space-constrained environments like packaging machinery.

DELTA TAU CLIPPER 603926-501 – High-voltage variant supporting 48V DC inputs, designed for heavy-duty industrial actuators.

DELTA TAU CLIPPER 603926-201 – Enhanced variant with dual-core processing and expanded memory for multi-tasking in large-scale robotic systems.

DELTA TAU CLIPPER 603926-001 – Entry-level model with basic 2-axis control, ideal for simple conveyor systems or test benches.

DELTA TAU CLIPPER 603926-301 – Redundant controller for fail-safe applications, ensuring uninterrupted operation in pharmaceutical or aerospace manufacturing.

DELTA TAU CLIPPER 603926-401 – Compact version of CLIPPER 603926-101, optimized for space-constrained environments like packaging machinery.

DELTA TAU CLIPPER 603926-501 – High-voltage variant supporting 48V DC inputs, designed for heavy-duty industrial actuators.

As a certified partner of DELTA TAU, Hainan Jinlin Electromechanical specializes in delivering motion control solutions for:

- Automotive assembly lines (e.g., robotic welding and pick-and-place systems).

- CNC machine tools (5-axis milling and turning applications).

- Semiconductor wafer handling (precision positioning in cleanroom environments).

If CLIPPER 603926-101 does not meet your exact requirements, our team will source alternative models from DELTA TAU’s portfolio or recommend compatible third-party devices. Contact us via WhatsApp or email (jllucky33@qq.com) for personalized assistance.

Leave a comment

Your email address will not be published. Required fields are marked *