Product Overview

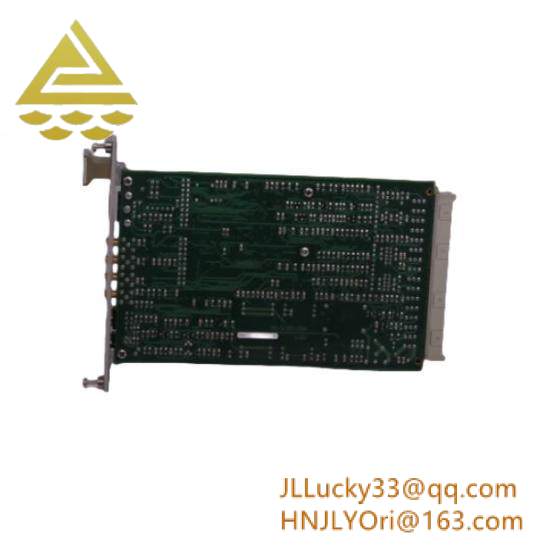

The DELTA TAU ACC-24E2A is a high-performance motion control I/O module designed for precision automation in industrial and manufacturing environments. As part of Delta Tau’s advanced ACC series, this module serves as a critical interface between motion controllers, sensors, and actuators, enabling real-time data exchange and command execution. Its core functionality lies in translating control signals from Delta Tau’s Power PMAC motion controllers into actionable outputs for servo drives, motors, and other peripherals. With 24 digital inputs and 2 analog outputs, the ACC-24E2A excels in applications requiring both discrete logic control (e.g., limit switches, safety interlocks) and analog signal management (e.g., temperature or pressure sensors).

The DELTA TAU ACC-24E2A is a high-performance motion control I/O module designed for precision automation in industrial and manufacturing environments. As part of Delta Tau’s advanced ACC series, this module serves as a critical interface between motion controllers, sensors, and actuators, enabling real-time data exchange and command execution. Its core functionality lies in translating control signals from Delta Tau’s Power PMAC motion controllers into actionable outputs for servo drives, motors, and other peripherals. With 24 digital inputs and 2 analog outputs, the ACC-24E2A excels in applications requiring both discrete logic control (e.g., limit switches, safety interlocks) and analog signal management (e.g., temperature or pressure sensors).

Ideal for CNC machining, robotics, and high-speed production lines, the ACC-24E2A integrates seamlessly with Delta Tau’s EtherCAT-based systems, ensuring sub-microsecond communication latency for synchronized multi-axis control. Its compact design and rugged construction make it suitable for harsh industrial settings, while compatibility with Delta Tau’s intuitive programming software simplifies system configuration and troubleshooting. Whether used in automotive assembly lines, aerospace machining, or semiconductor fabrication, the ACC-24E2A delivers reliability and precision to optimize operational efficiency.

Hainan Jinlin Electromechanical Equipment Co., Ltd., a certified distributor of Delta Tau products, specializes in delivering tailored automation solutions. With a focus on pre-sales technical guidance and post-sales support, the company ensures customers receive the right components for their applications, backed by a one-year warranty.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | DELTA TAU ACC-24E2A |

| Manufacturer | Delta Tau |

| Product Type | Motion Control I/O Module |

| Power Supply | 24V DC (18–30V input range) |

| Dimensions | 125mm x 75mm x 50mm (W x H x D) |

| Communication Protocol | EtherCAT (real-time deterministic) |

| Operating Temperature | -25°C to +70°C |

| Mounting Type | 35mm DIN rail (standard industrial) |

| Digital I/O | 24 inputs (24V DC,) |

| Analog Outputs | 2 channels (±10V, 16-bit resolution) |

Key Features and Benefits

The DELTA TAU ACC-24E2A stands out for its real-time EtherCAT communication, which enables ultra-fast data transfer and synchronization with Delta Tau’s Power PMAC controllers. This ensures precise coordination of complex motion sequences, such as high-speed contouring in CNC machines or dynamic robotic arm movements. The module’s 24 digital inputs support direct connection to proximity sensors, encoders, and safety devices, while its 2 analog outputs provide smooth, variable control for proportional valves or motor drives.

The DELTA TAU ACC-24E2A stands out for its real-time EtherCAT communication, which enables ultra-fast data transfer and synchronization with Delta Tau’s Power PMAC controllers. This ensures precise coordination of complex motion sequences, such as high-speed contouring in CNC machines or dynamic robotic arm movements. The module’s 24 digital inputs support direct connection to proximity sensors, encoders, and safety devices, while its 2 analog outputs provide smooth, variable control for proportional valves or motor drives.

Built for durability, the ACC-24E2A incorporates galvanic isolation on all I/O channels to protect against voltage spikes and electromagnetic interference (EMI), ensuring stable operation in electrically noisy environments. Its wide temperature range (-25°C to +70°C) and shock-resistant design make it suitable for both indoor and outdoor applications, from factory floors to outdoor processing plants.

Integration is simplified through Delta Tau’s Power PMAC software, which allows engineers to configure I/O mappings, diagnostics, and custom control logic using intuitive programming languages like C or G-code. This reduces development time and enables seamless integration with existing automation systems. Hainan Jinlin’s pre-sales team further supports customers by providing system design recommendations, while post-sales support includes firmware updates, troubleshooting, and on-site assistance.

For scalability, the ACC-24E2A can be daisy-chained with other Delta Tau I/O modules via EtherCAT, allowing users to expand I/O capacity without compromising performance. This flexibility is ideal for applications that require incremental upgrades, such as adding new robotic cells to a production line.

Related Models

DELTA TAU ACC-16E4A – A variant with 16 digital inputs and 4 analog outputs, designed for applications requiring a balance of discrete and analog control, such as packaging machinery or material handling systems.

DELTA TAU ACC-8E8A – Focuses on 8 digital inputs and 8 analog outputs, ideal for robotics applications where proportional control (e.g., joint actuators) is prioritized over discrete logic.

DELTA TAU ACC-48E2A – An enhanced version with 48 digital inputs and 2 analog outputs, suitable for large-scale systems requiring high-density discrete I/O, such as automotive assembly lines with extensive sensor networks.

DELTA TAU ACC-24E2A-EX – A ruggedized variant with explosion-proof certification, designed for hazardous environments like oil refineries or chemical processing plants.

DELTA TAU ACC-24E2A-USB – Includes a USB interface for standalone configuration and diagnostics, useful for prototyping or remote system monitoring.

DELTA TAU PMAC2/PC104 – A compact motion controller that pairs with the ACC-24E2A for standalone CNC or robotic applications, offering embedded processing and EtherCAT connectivity.

DELTA TAU ACC-24E2A-RTD – Specialized model with RTD input channels for temperature monitoring, tailored for HVAC systems or thermal processing equipment.

DELTA TAU ACC-16E4A – A variant with 16 digital inputs and 4 analog outputs, designed for applications requiring a balance of discrete and analog control, such as packaging machinery or material handling systems.

DELTA TAU ACC-8E8A – Focuses on 8 digital inputs and 8 analog outputs, ideal for robotics applications where proportional control (e.g., joint actuators) is prioritized over discrete logic.

DELTA TAU ACC-48E2A – An enhanced version with 48 digital inputs and 2 analog outputs, suitable for large-scale systems requiring high-density discrete I/O, such as automotive assembly lines with extensive sensor networks.

DELTA TAU ACC-24E2A-EX – A ruggedized variant with explosion-proof certification, designed for hazardous environments like oil refineries or chemical processing plants.

DELTA TAU ACC-24E2A-USB – Includes a USB interface for standalone configuration and diagnostics, useful for prototyping or remote system monitoring.

DELTA TAU PMAC2/PC104 – A compact motion controller that pairs with the ACC-24E2A for standalone CNC or robotic applications, offering embedded processing and EtherCAT connectivity.

DELTA TAU ACC-24E2A-RTD – Specialized model with RTD input channels for temperature monitoring, tailored for HVAC systems or thermal processing equipment.

Hainan Jinlin Electromechanical ensures professional support throughout the entire lifecycle of your automation project. All products, including the DELTA TAU ACC-24E2A, come with a one-year warranty and access to technical resources. For customized solutions or hard-to-find models, contact us via WhatsApp or email at jllucky33@qq.com. Our team is committed to delivering the right components to meet your operational demands.

Leave a comment

Your email address will not be published. Required fields are marked *