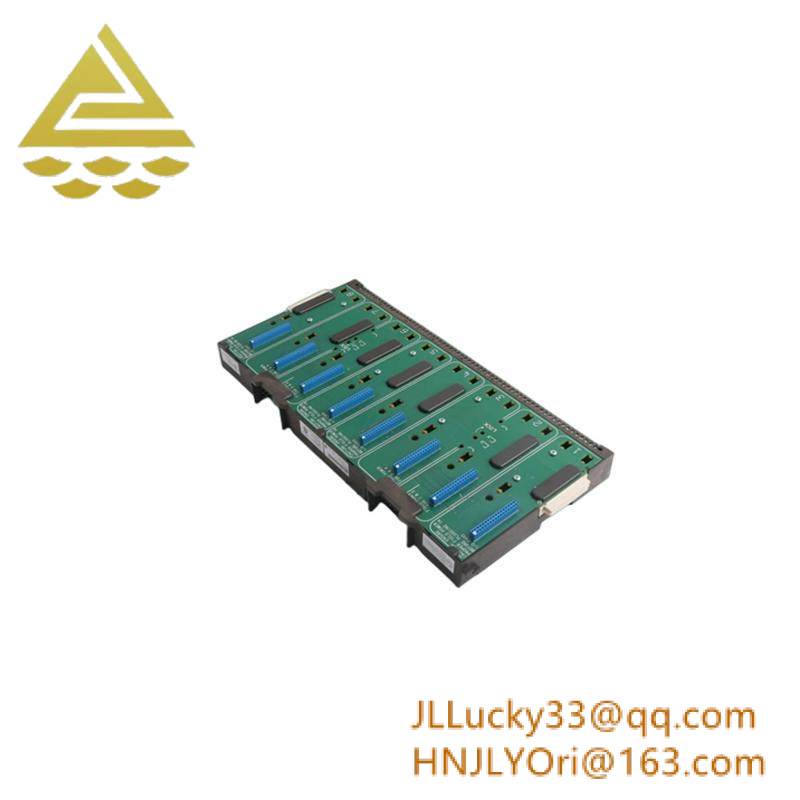

HIMA X-AI 16 51 Analysis Input Module

product overview

HIMA X-AI 16 51 is an analysis input module designed specifically for industrial safety systems, providing SIL 3 (IEC 61508/IEC 61511) level safety certification, suitable for real-time signal acquisition applications in industries such as petrochemicals and power (such as pressure and temperature monitoring). This module adopts a redundant architecture and fail safe design to ensure automatic switching to a safe state and output diagnostic codes in the event of channel failures, thereby improving the reliability of critical process control.

technical specifications

Parameter values

Model X-AI 16 51

16 input channels (independent isolation)

Input type voltage (0-10V, ± 10V), current (4-20mA, 0-20mA)

Accuracy voltage ± 0.05% FSR, current ± 0.02% FSR

Resolution 16 bits (65536 quantization levels)

Supply voltage 24V DC

Signal isolation ≥ 1500V AC (between channels)

Diagnostic response time ≤ 50 ms (disconnection/short circuit detection)

Communication protocols HIMax system bus, Ethernet/IP, PROFISAFE

Data update cycle ≤ 10 ms

Working environment -20 ° C to+60 ° C, humidity 5-95% RH (non condensing)

Protection level IP20

core features

SIL Level 3 safety mechanism:

Using a two out of three voting logic (2oo3), when any channel fails, it automatically switches to the preset safe state and generates a diagnostic code (such as E001 indicating channel disconnection).

Support dual bus redundant communication, seamless switching of backup bus within 5ms in case of main bus failure, maintaining data integrity.

Intelligent diagnosis and calibration:

Real time monitoring of input impedance (disconnection alarm: impedance>10M Ω; short circuit alarm: impedance<50 Ω), reducing false alarm rate to<0.001% 1.

Built in temperature compensation algorithm, automatically calibrates signal offset within the range of -20 ° C to+60 ° C, with long-term stability of ≤± 0.02% FSR/year.

Compatible with HART 7 protocol, capable of reading transmitter diagnostic data (such as sensor lifespan), supports predictive maintenance 1.

Modular expansion capability:

Hot swappable design supports live replacement (module replacement time<30 seconds), reducing system downtime by 90%.

Cascading up to 64 modules through the HIMax bus, expanding to 512 input channels to meet the requirements of large factories.

The SILworX tool simplifies configuration (such as range, filtering time, alarm threshold) and improves configuration efficiency by 80%.

Typical application scenarios

Safety critical monitoring: The pressure and temperature signals of the catalytic cracking unit in the refinery are collected with a response delay of less than 2ms.

Fault protection: Real time detection of sensor disconnection or signal overload (such as abnormal flow meter), triggering interlock shutdown.

Large scale system integration: Multi area redundant deployment in chemical plants, combined with controllers (such as HIMA H41q/H51q) to achieve centralized management

| GE | IS200TBAIHIC |

| GE | IS230TSVC2AG01 |

| GE | IS200TBAIHICDC |

| GE | IS200TRPAHIAFC |

| GE | IS200TSVCH2A |

Leave a comment

Your email address will not be published. Required fields are marked *