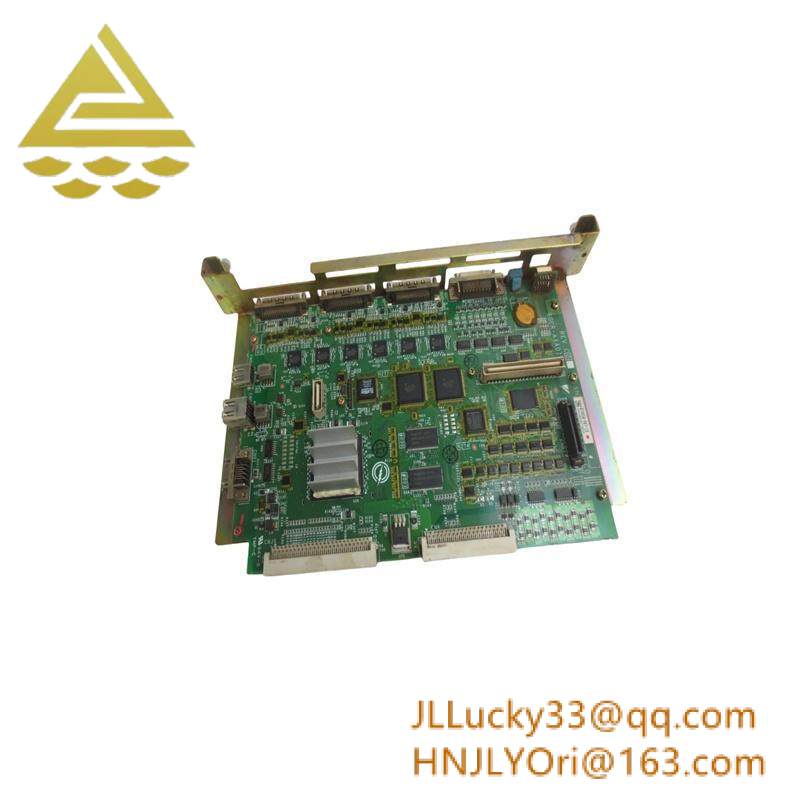

HIMA K7214 is a high-performance I/O module designed for use in safety-critical industrial automation systems. As part of HIMA’s SIL 3-certified Failsafe 3000 series, this module plays a vital role in ensuring reliable communication between safety controllers and field devices. Its core functionality lies in providing secure input and output channels for digital signals, enabling precise monitoring and control of industrial processes. The K7214 is engineered to meet the rigorous demands of industries such as oil and gas, chemical processing, and power generation, where system integrity and fault tolerance are paramount.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | HIMA K7214 |

| Manufacturer | HIMA |

| Product Type | Digital I/O Module |

| Channel Configuration | 16-channel digital input |

| Input Type | 24VDC, sinking/sourcing |

| Safety Integrity Level | SIL 3 (IEC 61508) |

| Response Time | <5 ms |

| Current Consumption | 10 mA per channel |

| Voltage Range | 20.4–28.8VDC |

| Protection | Overvoltage, short-circuit protection |

| Communication Interface | HIMA SafeEthernet |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5–95% RH (non-condensing) |

| Dimensions (W x H x D) | 130 x 150 x 120 mm |

| Weight | 0.8 kg |

| Certification | ATEX, IECEx, UL, CSA |

Key Features and Benefits

The HIMA K7214 distinguishes itself with its redundant, fault-tolerant design, which ensures continuous operation even in the event of a single-channel failure. Each channel is monitored independently, and any discrepancies are immediately detected and reported, allowing for swift corrective action. This high level of fault tolerance makes the K7214 ideal for applications where system downtime could have severe consequences.

The HIMA K7214 distinguishes itself with its redundant, fault-tolerant design, which ensures continuous operation even in the event of a single-channel failure. Each channel is monitored independently, and any discrepancies are immediately detected and reported, allowing for swift corrective action. This high level of fault tolerance makes the K7214 ideal for applications where system downtime could have severe consequences.

One of the module’s standout features is its high-speed response time, which enables rapid detection of critical events. This is particularly important in safety applications, where timely intervention can prevent accidents and protect personnel and equipment. The K7214also offers advanced filtering capabilities to eliminate electrical noise and ensure reliable signal transmission, even in harsh industrial environments.

The K7214 seamlessly integrates with HIMA’s Failsafe 3000 series controllers via SafeEthernet, providing a secure and efficient communication pathway. This integration allows for easy configuration and diagnostics, reducing setup time and simplifying maintenance. The module’s modular design further enhances flexibility, enabling it to be easily expanded or modified to meet changing system requirements.

Application Scenarios

The HIMA K7214 is widely used in industries where safety-critical monitoring and control are essential. In oil and gas production, the module is employed to monitor emergency shutdown valves, pressure sensors, and fire and gas detectors, ensuring that any 异常情况 can be quickly detected and addressed. Its ability to operate in extreme temperatures and harsh environments makes it well-suited for offshore platforms and remote pipeline installations.

The HIMA K7214 is widely used in industries where safety-critical monitoring and control are essential. In oil and gas production, the module is employed to monitor emergency shutdown valves, pressure sensors, and fire and gas detectors, ensuring that any 异常情况 can be quickly detected and addressed. Its ability to operate in extreme temperatures and harsh environments makes it well-suited for offshore platforms and remote pipeline installations.

In chemical processing plants, the K7214 is used to monitor critical process parameters such as temperature, pressure, and level, providing redundant safety layers to prevent overpressure, leaks, and other hazardous events. The module’s high-speed response time and fault tolerance are crucial for maintaining safe operating conditions in these environments.

In power generation facilities, the K7214 plays a vital role in protecting equipment and personnel by monitoring safety-critical systems such as turbine controls, boiler safety valves, and generator protection systems. Its reliable performance ensures that power generation processes can operate safely and efficiently.

Related Models

- HIMA K7215 – 16-channel digital output module.

- HIMA K7216 – Mixed digital I/O module (8 inputs/8 outputs).

- HIMA K7217 – High-density digital input module (32 channels).

- HIMA K7218 – Digital input module with extended temperature range.

- HIMA K7219 – Fault-tolerant digital output module.

Installation and Maintenance

Installing the HIMA K7214 requires careful attention to detail to ensure proper functionality and safety. The module should be mounted in a dedicated control panel or enclosure that provides adequate protection against environmental factors such as dust, moisture, and vibration. Proper grounding and shielding are essential to prevent electromagnetic interference and ensure reliable signal transmission. The module’s communication interfaces should be connected using certified cables and connectors to maintain safety integrity.

Installing the HIMA K7214 requires careful attention to detail to ensure proper functionality and safety. The module should be mounted in a dedicated control panel or enclosure that provides adequate protection against environmental factors such as dust, moisture, and vibration. Proper grounding and shielding are essential to prevent electromagnetic interference and ensure reliable signal transmission. The module’s communication interfaces should be connected using certified cables and connectors to maintain safety integrity.

Maintenance of the K7214 is designed to be straightforward and minimally invasive. Regular system checks should include monitoring diagnostic indicators, verifying communication links, and inspecting physical components for signs of wear. HIMA recommends performing firmware updates periodically to ensure the module has the latest security patches and functionality enhancements. These updates can be safely applied without disrupting system operation, thanks to the module’s redundant architecture. Additionally, the K7214‘s self-diagnostic capabilities provide early warning of potential issues, allowing for proactive maintenance and minimizing unplanned downtime.

Leave a comment

Your email address will not be published. Required fields are marked *