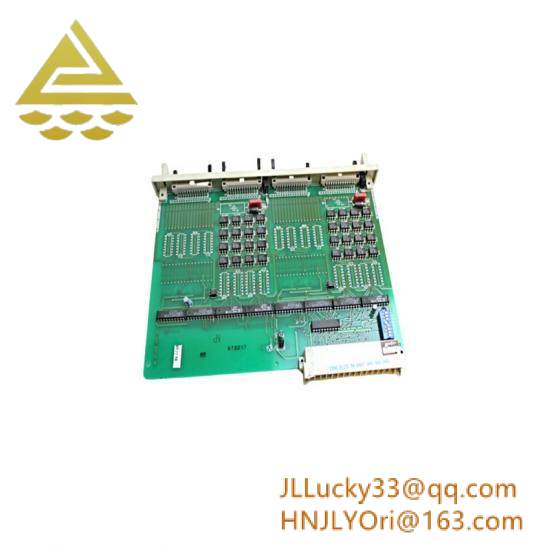

n industrial settings where safety is non-negotiable, the HIMA F8650A Safety Controller delivers reliable, high-integrity protection for critical processes. Designed for applications requiring SIL 3 certification, this compact controller combines advanced safety functionality with robust performance, making it ideal for use in industries such as oil and gas, chemical processing, power generation, and pharmaceuticals. Part of HIMA’s trusted HIMax® platform, the F8650A ensures fail-safe operation in demanding environments, safeguarding personnel, assets, and the environment.

The HIMA F8650A serves as the core of safety instrumented systems (SIS), executing critical functions such as emergency shutdown (ESD), fire and gas detection (F&G), and burner management. Its modular design allows for flexible configuration, supporting a wide range of input/output modules to interface with sensors and actuators. The controller processes data at high speeds, enabling rapid response to potential hazards while maintaining continuous monitoring of system integrity. With its redundant architecture and fault-tolerant design, the F8650A ensures that safety functions remain operational even in the event of component failures, minimizing the risk of unplanned downtime.

| Label | Specification |

|---|---|

| Model Number | F8650A |

| Brand | HIMA |

| Type | Safety Controller |

| Architecture | 2oo4D (Two-out-of-Four with Diversity) |

| Safety Integrity Level | SIL 3 (IEC 61508) |

| Processor | Dual-core, 32-bit RISC |

| Memory | 2 GB RAM, 8 GB Flash |

| I/O Capacity | Up to 1,024 I/O points |

| Communication | PROFIsafe, Modbus TCP, Ethernet/IP |

| Operating Temp | -20°C to +60°C |

| Power Supply | 24 V DC (redundant) |

| Dimensions | 483 x 210 x 130 mm |

| Weight | 6.5 kg |

| Certifications | IEC 61508, IEC 61511, SIL 3, TÜV, CSA |

The HIMA F8650A stands out for its innovative 2oo4D architecture, which combines redundancy with diversity to eliminate single points of failure. This design features four independent processor channels arranged in two pairs, each running a different software variant. The controller continuously compares the outputs of these pairs, ensuring that any discrepancies are immediately detected and addressed. This approach provides both high availability and fault tolerance, making the F8650A suitable for applications with the most stringent safety requirements.

In addition to its robust architecture, the HIMA F8650A offers advanced diagnostic capabilities that continuously monitor the controller’s health and performance. These diagnostics detect potential issues before they escalate, allowing for proactive maintenance and minimizing unplanned downtime. The controller also supports hot-swappable modules, enabling maintenance and upgrades without interrupting critical safety functions. Its modular design provides flexibility, allowing users to configure the system to meet specific application requirements while ensuring scalability for future expansions.

The HIMA F8650A is widely used in industries where safety-critical operations are essential. In oil and gas production facilities, the controller manages emergency shutdown systems, ensuring that operations can be safely halted in the event of a leak, fire, or other hazardous conditions. In chemical plants, it monitors processes to prevent overpressure, temperature excursions, and other potential safety risks. The controller’s high-speed response time and reliability make it ideal for protecting against rapid-onset hazards, such as chemical spills or explosions.

In power generation, the HIMA F8650A is employed in burner management systems to ensure safe ignition and operation of boilers and turbines. It also plays a crucial role in nuclear power plants, where it monitors safety-critical parameters and controls shutdown systems to prevent radiation leaks. Across all these applications, the F8650A provides the confidence that safety functions will operate as intended, even under the most challenging conditions.

Related models in HIMA’s product portfolio include:

- F8641: A larger, higher-capacity safety controller designed for complex applications with extensive I/O requirements.

- F8661: A high-performance safety controller with enhanced processing power and expanded communication capabilities.

- F8671: A safety controller optimized for use in explosion-proof environments, featuring ruggedized construction and hazardous area certifications.

- F8681: A redundant safety controller with advanced fault-tolerant capabilities, ideal for applications requiring the highest levels of availability.

- F8691: A safety controller specifically designed for use in railway and transportation applications, meeting strict industry standards for safety and reliability.

Installation of the HIMA F8650A requires adherence to strict guidelines to ensure compliance with safety standards. The controller should be mounted in a dedicated enclosure with proper ventilation and protection against environmental factors such as dust and moisture. Electrical connections must be carefully routed and secured to prevent interference and ensure signal integrity. HIMA provides detailed installation and wiring diagrams, as well as comprehensive documentation to support compliance with relevant safety regulations.

Maintenance of the HIMA F8650A is streamlined through its self-diagnostic capabilities, which continuously monitor system health and alert operators to potential issues. Routine maintenance includes visual inspections, firmware updates, and periodic testing of safety functions to ensure they remain operational. HIMA offers training programs to help maintenance personnel understand the controller’s features and perform necessary tasks effectively. In the event of a component failure, the controller’s modular design allows for quick replacement of faulty modules, minimizing downtime and ensuring continuous safety protection.

Leave a comment

Your email address will not be published. Required fields are marked *