FIRE 95DSS2-1 Product Description

Product Overview

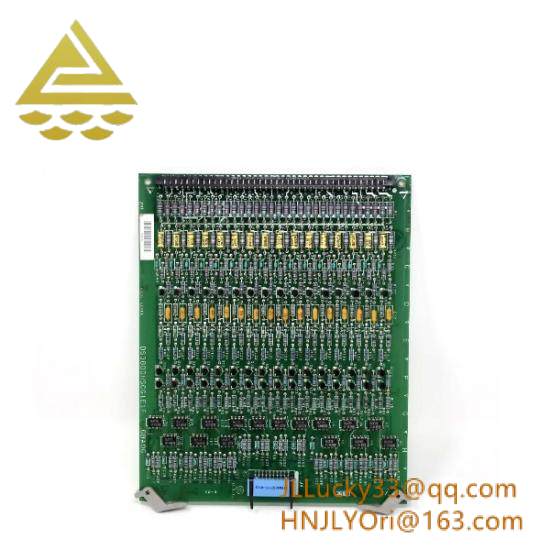

The FIRE 95DSS2-1 is a high-performance flame scanner, meticulously engineered to provide reliable flame detection in industrial combustion systems. As a critical component in fire safety and combustion control, this scanner leverages advanced optical sensing technology to accurately identify the presence or absence of flames, ensuring the safe and efficient operation of boilers, furnaces, incinerators, and other industrial heating equipment.

Developed by FIRE, a leading manufacturer in industrial flame monitoring solutions, the FIRE 95DSS2-1 is designed to excel in harsh industrial environments. It can detect flames from a variety of fuel sources, including natural gas, oil, and coal, making it versatile across diverse applications such as power generation plants, chemical processing facilities, and manufacturing plants. Its robust construction and precise detection capabilities minimize the risk of false alarms and missed flame failures, enhancing overall system safety and reducing operational downtime.

Hainan Jinlin Mechanical & Electrical, a trusted distributor of industrial control products, offers the FIRE 95DSS2-1 flame scanner. We adhere to the “Customer First, Forge Ahead” business philosophy, providing comprehensive support for installation, calibration, and maintenance to ensure optimal performance.

Technical Specifications

|

Parameter

|

Value

|

|

Product Model

|

FIRE 95DSS2-1

|

|

Manufacturer

|

FIRE

|

|

Product Type

|

Industrial Flame Scanner

|

|

Sensing Technology

|

Dual-spectrum (ultraviolet (UV) and infrared (IR))

|

|

Detection Wavelengths

|

UV: 185-260 nm; IR: 4.3 μm (targeting CO₂ emission)

|

|

Fuel Compatibility

|

Natural gas, oil, coal, biomass, and other hydrocarbon fuels

|

|

Response Time

|

< 1 second (flame presence); < 2 seconds (flame loss)

|

|

Operating Temperature

|

-40°C to 85°C

|

|

Enclosure Material

|

Cast aluminum with high-temperature epoxy coating

|

|

Enclosure Rating

|

NEMA 4X (IP66)

|

|

Power Supply

|

24 VDC ± 10%

|

|

Output Signal

|

Relay (SPDT, 5 A @ 250 VAC) and 4-20 mA analog

|

|

Cable Length

|

10 ft (3 m) shielded cable

|

|

Certifications

|

UL, FM, CSA, ATEX, IECEx

|

Key Features and Benefits

Dual-Spectrum Detection: The FIRE 95DSS2-1 utilizes both UV and IR sensing technologies to distinguish between genuine flames and false signals. The UV sensor detects the short-wavelength radiation emitted during combustion, while the IR sensor targets the 4.3 μm wavelength specific to CO₂, a byproduct of hydrocarbon combustion. This dual approach eliminates false alarms from sources like hot refractory materials, arc welding, or sunlight, ensuring reliable detection in challenging environments—such as coal-fired boilers with heavy soot buildup.

Wide Fuel Compatibility: Designed to detect flames from a broad range of fuels, including natural gas, oil, coal, and biomass, the scanner adapts to diverse industrial processes. In a biomass power plant, for example, it can reliably detect flames from wood pellets or agricultural waste, even with varying moisture content or combustion characteristics.

Extreme Environment Durability: With a NEMA 4X (IP66) enclosure and operating temperature range of -40°C to 85°C, the FIRE 95DSS2-1 thrives in harsh conditions. Its cast aluminum housing with high-temperature epoxy coating resists corrosion, vibration, and water ingress, making it suitable for outdoor installations (e.g., waste-to-energy incinerators) or coastal facilities exposed to salt spray.

Rapid Response Times: The scanner’s fast response to flame presence (< 1 second) and loss (< 2 seconds) ensures timely activation of safety systems. In a gas-fired furnace, for instance, it can trigger fuel valve shutdowns within seconds of flame loss, preventing unburned gas accumulation and potential explosions.

Flexible Output Options: Equipped with both relay and analog outputs, the FIRE 95DSS2-1 integrates seamlessly with combustion control systems, PLCs, and SCADA networks. The relay output can directly actuate safety shutdowns, while the 4-20 mA signal provides continuous flame intensity data for process optimization—useful in adjusting fuel-air mixtures for efficiency in industrial boilers.

Related Models

- FIRE 95DSS1-1: A single-spectrum (IR-only) variant, ideal for applications with consistent fuel types (e.g., natural gas boilers) where UV detection is unnecessary. It offers a cost-effective alternative to the FIRE 95DSS2-1 for simpler combustion systems.

- FIRE 95DSS2-2: A long-cable version with a 20 ft (6 m) cable, designed for installations where the scanner must be positioned far from the control cabinet—such as large industrial furnaces with extended combustion chambers. It retains all features of the FIRE 95DSS2-1 but with enhanced cable length.

- FIRE 95DSS2-EX: An explosion-proof model certified for Zone 0/1 hazardous areas, featuring reinforced housing and intrinsic safety barriers. It is suitable for oil refineries or chemical plants where flammable vapors may be present, offering enhanced safety over the standard FIRE 95DSS2-1.

- FIRE 95USS2-1: A UV-only scanner optimized for high-temperature applications (up to 120°C), such as glass manufacturing kilns. It lacks the IR sensor of the FIRE 95DSS2-1 but excels in environments where UV radiation is the primary flame signature.

As a certified partner of industry leaders, we supply components for diverse sectors. The FIRE 95DSS2-1 is critical in power generation (coal/gas-fired turbines), chemical processing (reactor heating systems), waste management (incinerators), and manufacturing (heat-treating furnaces).

We offer a one-year warranty for the FIRE 95DSS2-1 flame scanner. Our pre-sales team provides guidance on mounting, calibration, and system integration, while after-sales support includes troubleshooting and replacement services. If you need detailed specifications or have specific application requirements, contact us immediately—we’re committed to delivering tailored solutions for your flame monitoring needs.

Leave a comment

Your email address will not be published. Required fields are marked *