Product Overview

The DSBC172 is a high-power industrial servo drive engineered to handle heavy-duty motion control applications, pairing seamlessly with large servo motors in demanding automation systems. Designed for precision and durability, this drive is a critical component in industrial presses, large-scale CNC machining centers, heavy-load robotic arms, and high-torque material handling equipment. Core features include enhanced current output, advanced motion control algorithms, and expanded connectivity options, ensuring stable performance even under extreme load fluctuations. The DSBC172 distinguishes itself with a rugged enclosure and efficient thermal management, making it suitable for continuous operation in harsh industrial environments. Whether integrated into new production lines or upgrading legacy systems, the DSBC172 delivers the power and precision needed to optimize heavy-duty automation processes.

Technical Specifications

|

Parameter

|

Value

|

|

Product Model

|

DSBC172

|

|

Manufacturer

|

[Brand]

|

|

Product Type

|

Servo Drive

|

|

Rated Output Current

|

17 A (continuous), 51 A (peak)

|

|

Input Voltage

|

380-480 VAC, 3-phase

|

|

Control Modes

|

Position, speed, torque control, electronic gearing

|

|

Communication Interfaces

|

EtherCAT, PROFINET, Modbus RTU, CANopen

|

|

Operating Temperature

|

-10°C to +60°C

|

|

Dimensions (W x H x D)

|

150 mm x 220 mm x 180 mm

|

|

Protection Class

|

IP20 (enclosure)

|

Key Features and Benefits

High-Power Performance

The DSBC172 delivers a robust 17 A continuous current (51 A peak), making it ideal for heavy-duty applications requiring high torque, such as large robotic arms lifting heavy payloads or industrial presses forming thick metal sheets. Its ability to maintain precise control under peak loads ensures smooth operation during rapid acceleration or deceleration, reducing mechanical stress on connected equipment and extending service life. This power capability allows the DSBC172 to handle motors up to 11 kW, covering a wide range of heavy-industry needs.

Advanced Control and Synchronization

Beyond standard position, speed, and torque modes, the DSBC172 includes electronic gearing functionality, enabling precise coordination between multiple axes in systems like multi-axis robotic assemblies or synchronized conveyor lines. The drive’s high-speed processing ensures response times under 1 ms, critical for applications where split-second adjustments are needed—such as in aerospace component machining, where tolerances are measured in microns. This level of control minimizes errors and enhances overall production accuracy.

Expanded Connectivity and Integration

Equipped with EtherCAT, PROFINET, Modbus RTU, and CANopen, the DSBC172 seamlessly integrates into complex industrial networks, supporting real-time data exchange with PLCs, SCADA systems, and HMIs. PROFINET compatibility simplifies integration into factory-wide Ethernet architectures, enabling remote monitoring and diagnostics. The drive’s flexible communication options reduce integration time in both new installations and retrofits, making it a versatile choice for diverse automation ecosystems.

Enhanced Durability and Protection

The DSBC172 features a comprehensive protection suite, including overcurrent, overvoltage, undervoltage, overheating, short-circuit, and motor overload protection, safeguarding both the drive and connected motor from damage in harsh conditions. Its rugged design withstands voltage transients and electromagnetic interference (EMI), ensuring reliable operation in environments with heavy machinery. The advanced thermal management system, featuring a large heatsink and variable-speed cooling fan, allows continuous operation at full load up to 60°C, reducing downtime in high-temperature industrial settings.

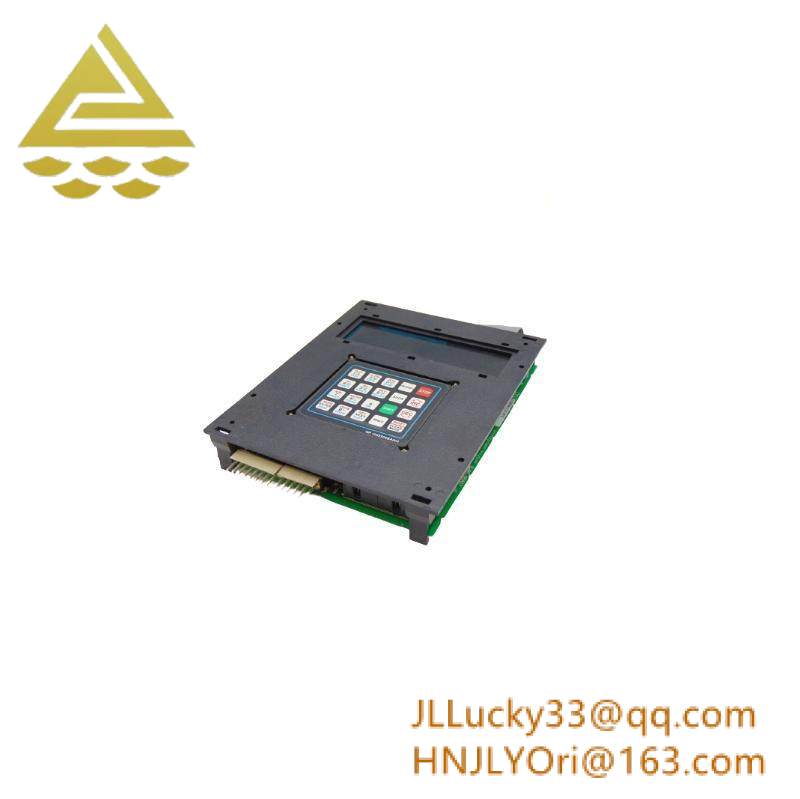

User-Friendly Configuration

Configuring the DSBC172 is intuitive via a high-resolution color LCD display with a navigation keypad, or through dedicated software (compatible with Windows and Linux). The software offers advanced tools like auto-tuning for motor parameters, vibration suppression, and multi-axis synchronization, streamlining commissioning for engineers. Saved configurations can be cloned across multiple drives, ensuring consistency in large-scale systems. This user-centric design reduces setup time and minimizes errors in complex installations.

Related Models

- DSBC142 – Mid-range variant (14 A continuous) for medium-heavy applications like large conveyor systems or mid-sized robotic arms.

- DSBC202 – Higher-power model (20 A continuous) for extreme-duty tasks such as large forging presses or mining equipment automation.

- DSBC172-EC – Enhanced communication version with additional EtherNet/IP interface, ideal for integration into Allen-Bradley-based networks.

- DSBC172-EX – Explosion-proof variant certified for ATEX Zone 1, suitable for hazardous areas like chemical processing or oil refineries.

- DSBC172-W – Wide-temperature model operating from -25°C to +65°C, designed for extreme environments like cold storage facilities or foundries.

- DSBC172-P – Panel-mount version with front-facing connectors and reinforced enclosure, simplifying installation in operator-accessible control panels.

As a professional distributor of industrial control products, we provide expert pre-sales support to help you verify if the DSBC172 is compatible with your heavy-duty servo motor and application requirements. Our after-sales service includes installation guidance, troubleshooting, and software configuration assistance. All drives, including the DSBC172, come with a one-year warranty. For more details or to inquire about other models, contact us via WhatsApp: [https://wa.me/+86 19389860630] or email: jllucky33@qq.com.

Leave a comment

Your email address will not be published. Required fields are marked *