Product Overview

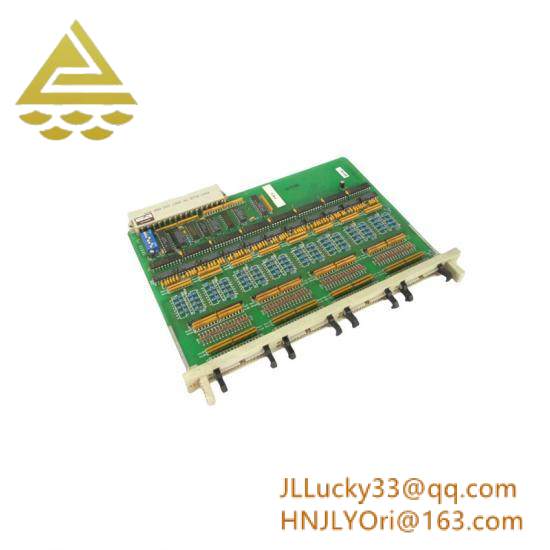

The DSBC111 is a high-performance industrial servo drive designed to complement precision servo motors in medium-duty automation systems. Engineered for seamless integration and reliable control, this drive is a key component in applications such as automated assembly lines, CNC machinery, robotic arms, and material handling systems. Core features include advanced motion control algorithms, flexible connectivity options, and robust protection mechanisms, ensuring precise motor operation even in dynamic load conditions. The DSBC111 stands out for its compact design, which saves space in control cabinets, and its user-friendly configuration interface, simplifying setup and commissioning. Whether deployed in new installations or system upgrades, the DSBC111 delivers consistent performance to optimize motion control accuracy and efficiency.

Technical Specifications

|

Parameter

|

Value

|

|

Product Model

|

DSBC111

|

|

Manufacturer

|

[Brand]

|

|

Product Type

|

Servo Drive

|

|

Rated Output Current

|

11 A (continuous), 33 A (peak)

|

|

Input Voltage

|

200-240 VAC, 3-phase

|

|

Control Modes

|

Position, speed, torque control

|

|

Communication Interfaces

|

EtherCAT, Modbus RTU, CANopen

|

|

Operating Temperature

|

0°C to +55°C

|

|

Dimensions (W x H x D)

|

120 mm x 180 mm x 150 mm

|

|

Protection Class

|

IP20 (enclosure)

|

Key Features and Benefits

Versatile Control Capabilities

The DSBC111 supports multiple control modes—position, speed, and torque—making it adaptable to diverse automation tasks. In position mode, it enables sub-micron positioning accuracy, critical for applications like PCB assembly or precision welding. Speed mode ensures stable rotation even with varying loads, ideal for conveyor systems or spindle drives. Torque mode provides precise force control, essential in tasks such as material clamping or delicate part handling. This versatility allows the DSBC111 to meet the demands of complex motion sequences with minimal reconfiguration.

、

、Advanced Connectivity and Integration

Equipped with EtherCAT, Modbus RTU, and CANopen interfaces, the DSBC111 seamlessly connects to PLCs, HMIs, and other automation components, enabling real-time data exchange and centralized control. EtherCAT support ensures high-speed synchronization (up to 1000 Hz update rates) in multi-axis systems, such as robotic arms with coordinated motion. The drive’s compatibility with industry-standard protocols simplifies integration into existing networks, reducing retrofitting time and costs.

Robust Protection and Reliability

The DSBC111 incorporates comprehensive protection features, including overcurrent, overvoltage, undervoltage, overheating, and short-circuit protection, safeguarding both the drive and connected motor from damage. Its rugged design withstands voltage fluctuations and electromagnetic interference (EMI) common in industrial environments, ensuring uninterrupted operation. The drive’s thermal management system efficiently dissipates heat, allowing it to operate at full load within a 0°C to +55°C range without derating—enhancing reliability in demanding conditions.

User-Friendly Configuration

Setting up the DSBC111 is streamlined via a built-in LCD display and keypad, or through dedicated software (compatible with Windows and Linux). The software provides advanced tuning tools, such as auto-tuning for motor parameters and vibration suppression, reducing commissioning time for engineers. Saved configurations can be cloned to multiple drives, ensuring consistency in multi-axis systems. This user-centric design minimizes setup errors and accelerates time-to-production.

Related Models

- DSBC081 – Lower current variant (8 A continuous) for smaller motors in light-duty applications like 3D printers or lab automation.

- DSBC151 – Higher current model (15 A continuous) for larger motors in heavy-duty tasks such as industrial presses or large conveyors.

- DSBC111-EC – Enhanced communication version with additional PROFINET interface, ideal for factory-wide Ethernet networks.

- DSBC111-EX – Explosion-proof variant certified for ATEX Zone 2, suitable for hazardous areas like chemical processing plants.

- DSBC111-W – Wide-temperature model operating from -20°C to +60°C, designed for extreme environments like cold storage facilities.

- DSBC111-P – Panel-mount version with front-facing connectors, simplifying installation in operator-accessible control panels.

As a professional distributor of industrial control products, we offer expert pre-sales support to help you determine if the DSBC111 is compatible with your servo motor and application requirements. Our after-sales service includes installation guidance, troubleshooting, and software configuration assistance. All drives, including the DSBC111, come with a one-year warranty. For more details or to inquire about other models, contact us via WhatsApp: [https://wa.me/+86 19389860630] or email: jllucky33@qq.com.

Leave a comment

Your email address will not be published. Required fields are marked *