Product Overview

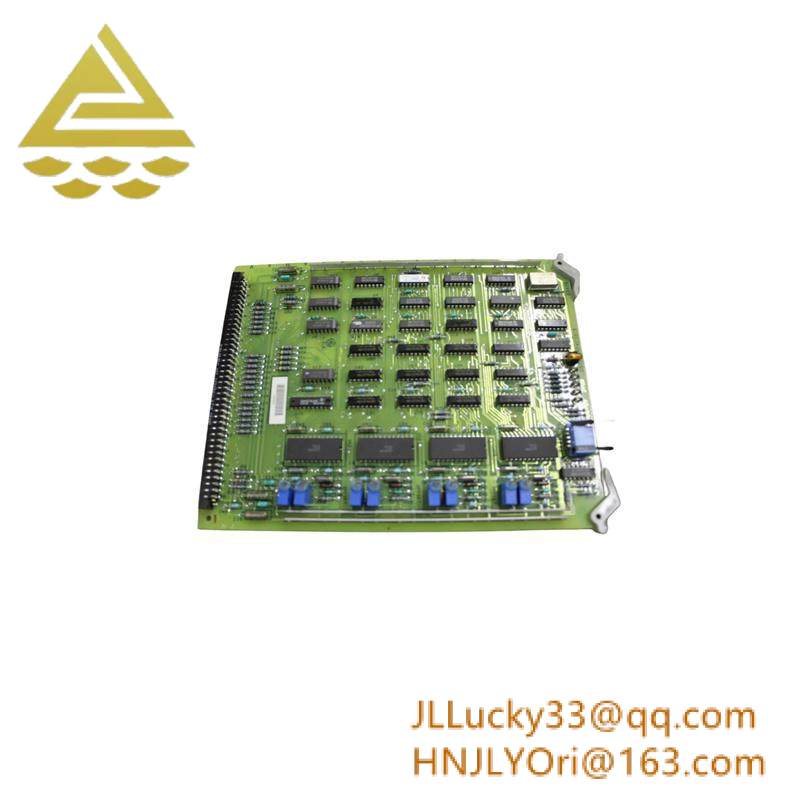

The WOODWARD 9907-164 is a digital microprocessor-based controller module engineered for precision speed regulation in industrial turbines, generators, and rotating machinery23. As a core component of Woodward’s control systems, it dynamically adjusts engine or turbine speed by processing real-time sensor data and executing advanced control algorithms24. Designed for harsh environments, this module integrates seamlessly into automation setups requiring vibration resistance, thermal stability, and fail-safe operation1. Its modular architecture simplifies maintenance and upgrades, while compatibility with Woodward’s 505 governor systems ensures broad applicability across power generation and marine propulsion sectors23. The WOODWARD 9907-164 delivers critical reliability for mission-critical processes where operational continuity is paramount15.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | WOODWARD 9907-164 |

| Manufacturer | Woodward |

| Product Type | Digital Controller Module |

| Input Voltage | 24V DC ±10% |

| Operating Temperature | -30°C to +70°C |

| Communication Protocol | Modbus RTU/TCP |

| Vibration Resistance | 5g @ 10–500 Hz |

| Protection Rating | IP52 (Dust/Water Resistant) |

Key Features and Benefits

1. Robust Performance in Extreme Conditions

The WOODWARD 9907-164 withstands sustained vibrations (up to 5g) and wide temperature fluctuations (-30°C to +70°C), ensuring stability in power plants and offshore platforms15. Its hardened enclosure (IP52) protects against dust ingress and moisture, extending service life in corrosive environments1.

2. Adaptive Control Algorithms

Leveraging real-time microprocessor technology, the module dynamically optimizes speed setpoints for turbines or engines, minimizing overshoot and improving fuel efficiency24. Support for PID tuning allows customization for diverse mechanical loads2.

3. Seamless System Integration

Compatible with Woodward’s 505 governor series and third-party PLCs via Modbus, the WOODWARD 9907-164 enables unified control architectures23. Hot-swappable design reduces downtime during replacements2.

4. Predictive Diagnostics

Integrated health-monitoring LEDs and software tools provide early warnings for component degradation, enabling proactive maintenance and reducing unplanned outages45.

5. Operational Flexibility

Configurable for remote or local operation, the module supports manual override capabilities for emergency scenarios, enhancing operational safety

| woodward | 5463-631 |

| woodward | 5463-716 |

| woodward | 5463-729 |

| woodward | 5463-750 |

| woodward | 5464-655 |

Leave a comment

Your email address will not be published. Required fields are marked *