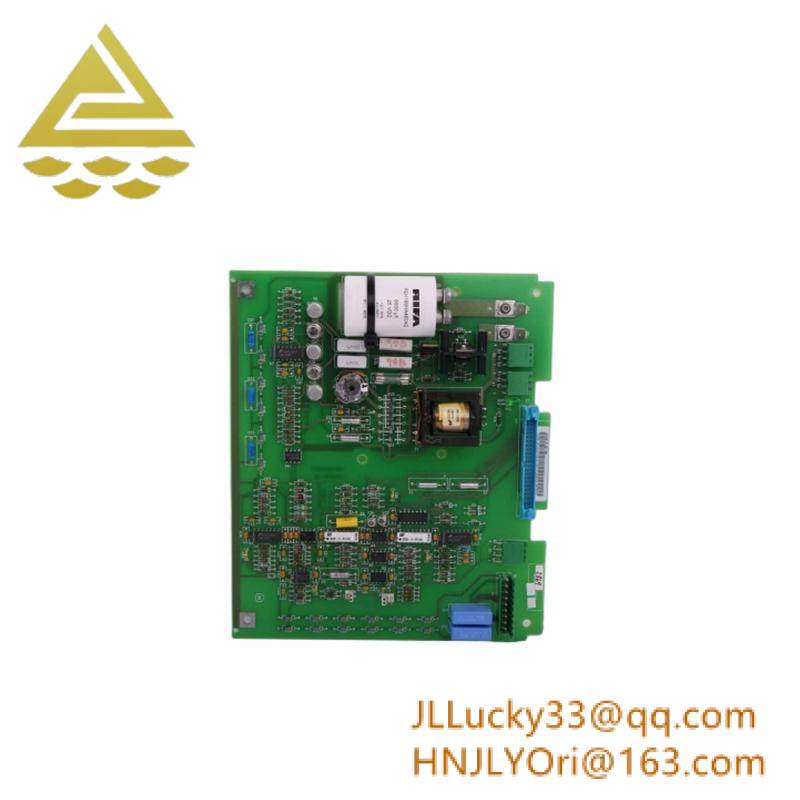

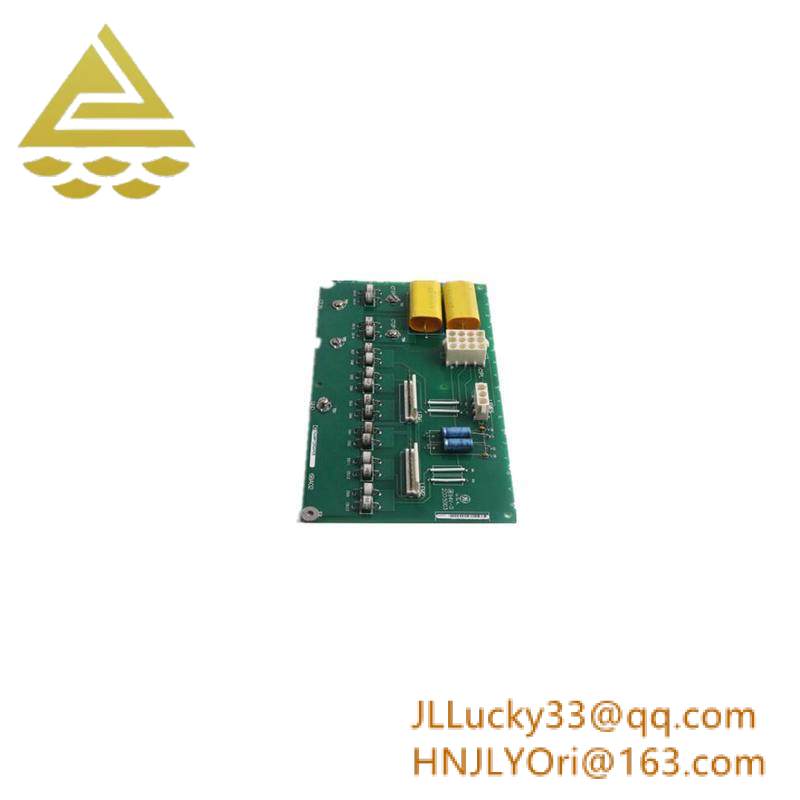

Product Overview

The Woodward 8200-1302 is a digital governor operator control panel engineered for precision speed regulation and position control in steam turbines, gas engines, and rotating industrial machinery24. As part of Woodward’s 505 series, it integrates triple-redundant architecture (TMR) to ensure operational integrity during component failures23, making it indispensable for power generation, oil refineries, and critical process industries. This unit combines a graphical interface with tactile controls, enabling real-time adjustments for parameters like speed, load dynamics, and critical speed avoidance24. Its industrial-grade design (IP65-rated) withstands harsh environments, while Modbus/Ethernet connectivity ensures seamless integration with DCS/PLC systems3. The Woodward 8200-1302 reduces mechanical stress and energy waste through ±0.05% speed accuracy and sub-10ms response times3.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | Woodward 8200-1302 |

| Manufacturer | Woodward |

| Product Type | Digital Governor (Operator Control Panel) |

| Input Voltage | 24 VDC |

| Operating Temperature | -40°C to +85°C |

| Speed Inputs | 2 (redundant) |

| Control Outputs | 2 × 4-20mA |

| Relay Outputs | 8 × Form C contacts |

| Communication Protocols | Modbus, Ethernet |

| Protection Rating | IP65 |

Key Features and Benefits

1. Intuitive Operator Interface

Featuring an integrated graphical display, navigation keys, and dedicated emergency trip button, the panel simplifies turbine adjustments and system diagnostics4. Users toggle between configuration, operation, and calibration modes for streamlined workflows4.

2. Advanced Control Capabilities

Automates cold/hot start sequencing with temperature-sensitive logic and avoids critical speed zones through three-segment avoidance algorithms24. Dual-speed/load dynamics optimize turbine efficiency during load shifts4.

3. Robust I/O Flexibility

Supports 8 configurable analog inputs (27 function options), 20 digital contact inputs, and redundant speed inputs compatible with magnetic pickups or eddy probes4. Two 4-20mA control outputs drive actuators, while 8 relay outputs handle alarms/trips4.

4. Triple Modular Redundancy

TMR architecture maintains speed control integrity during single-point failures, critical for safety systems in power plants3.

5. Comprehensive Diagnostics

Logs trip/alarm events with real-time timestamps, provides peak speed indicators for overspeed trips, and enables zero-speed detection for failure analysis24.

Related Models

- 8200-1301: Standard operator panel with dual-channel redundancy.

- 8200-1300: Base model for essential turbine control tasks.

- 505/ADAPT: Legacy variant with simplified programming.

- DSG-B07112: Networking gateway for Woodward protocols.

Why Choose Us?

Hainan Jinlin Electromechanical, an authorized Woodward distributor, supplies genuine 8200-1302 units with 1-year warranty and lifecycle support. Our experts assist with configuration, integration, and field maintenance—ensuring optimal turbine performance.

Contact: WhatsApp | Email: jllucky33@qq.com

| woodward | 5503-335 |

| woodward | 6945-377 |

| woodward | 8200-015 |

| woodward | 8200-019 |

Leave a comment

Your email address will not be published. Required fields are marked *