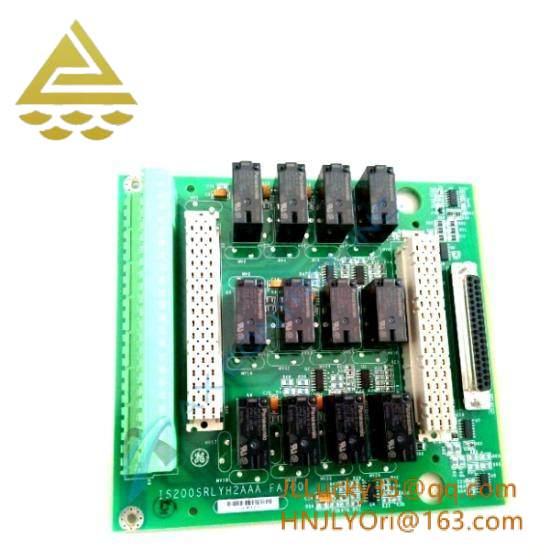

Digital Input Module | Allen-Bradley 74102-468-51

Product Overview

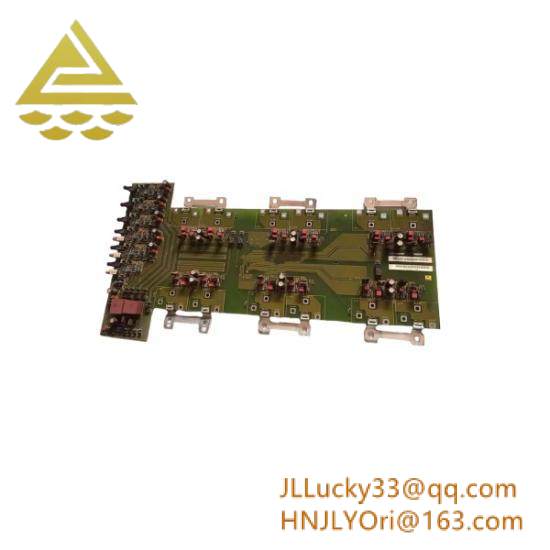

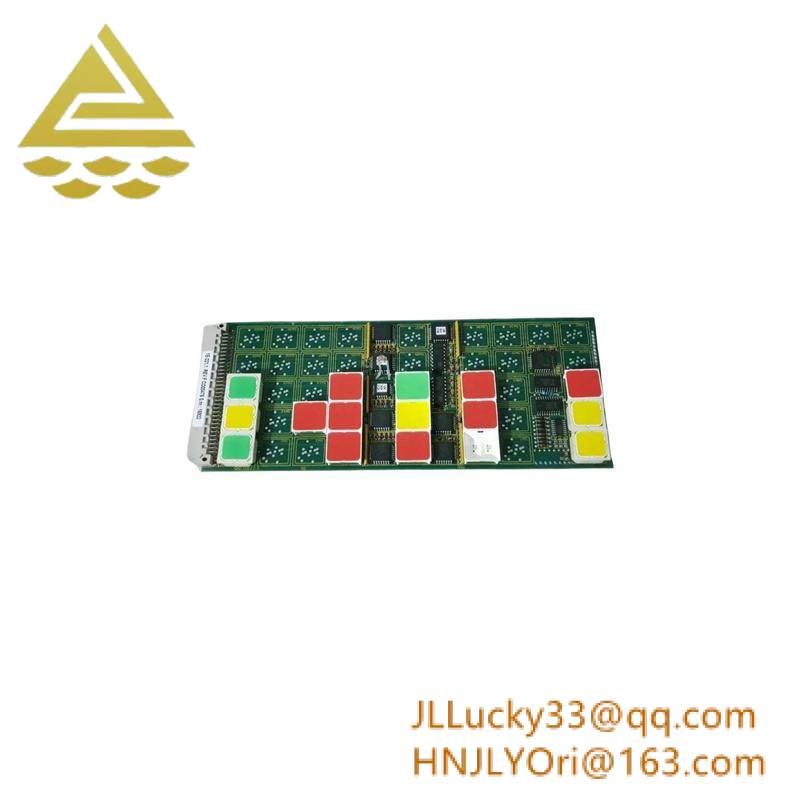

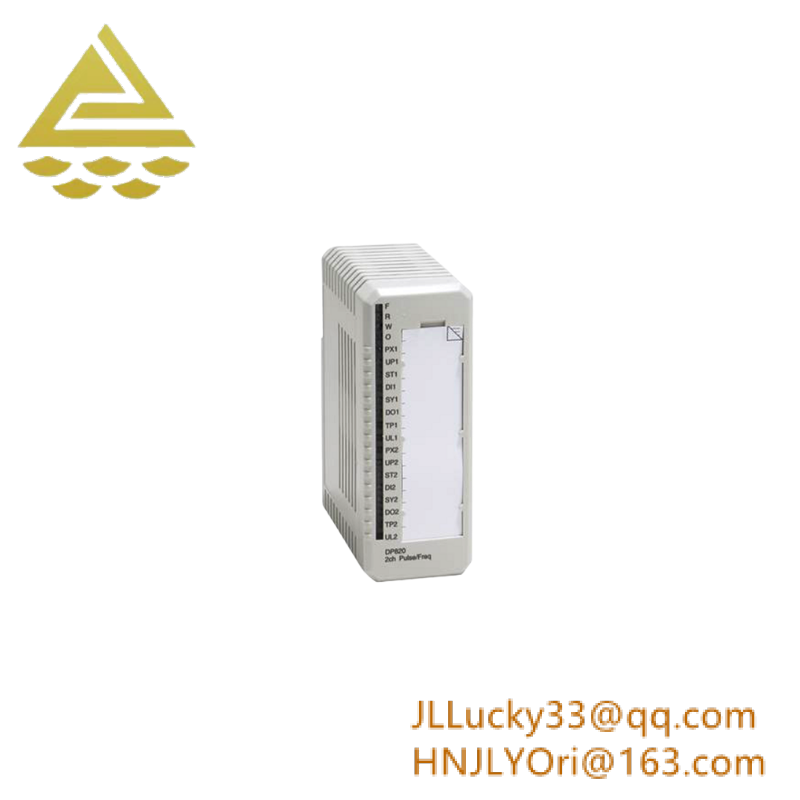

The Allen-Bradley 74102-468-51 is designed to provide reliable data acquisition and signal conditioning. It can monitor various digital signals and is widely used in manufacturing plants, energy facilities, and other places. This module has a compact design and supports quick – installation, which can effectively reduce the installation time and downtime of the system.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | 74102-468-51 |

| Manufacturer | Allen – Bradley |

| Product Type | Digital Input Module |

| Rated Voltage | 480V AC |

| Input Voltage Range | 10 – 30V DC |

| Power Range | 0.5 hp to 400 hp |

| Communication Interfaces | Ethernet/IP, DeviceNet |

| Operating Temperature Range | – 40°C to 85°C |

| Protection Level | IP20 |

| Response Time | Less than 1 ms |

| Number of Input Channels | 16 channels |

Key Features and Benefits

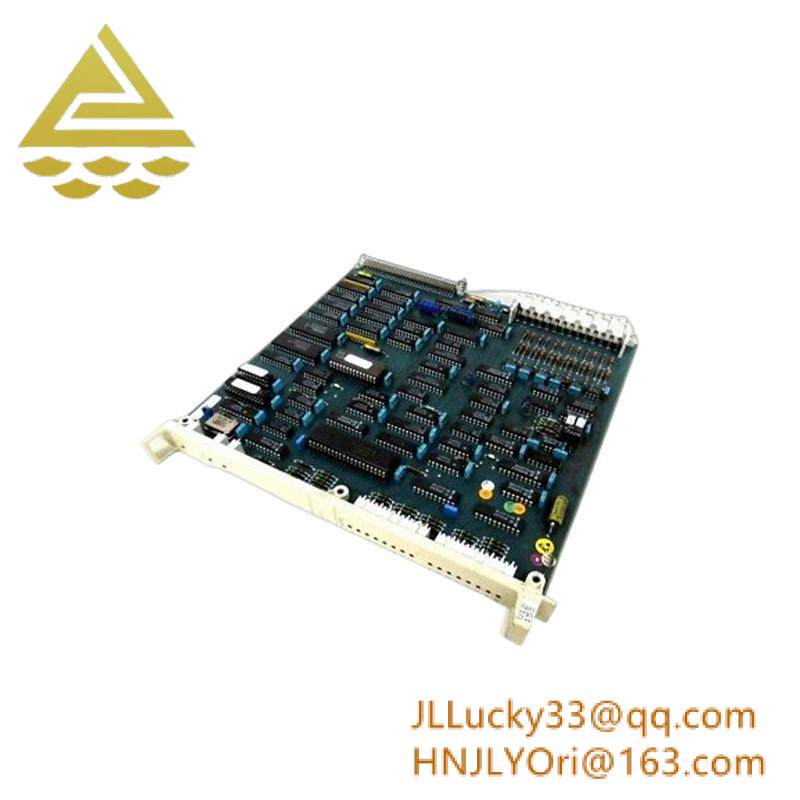

The 74102-468-51 has multiple outstanding features. It supports up to 16 – channel digital inputs and can accept both dry – contact and wet – contact types, which has strong versatility in integration with different sensors and control devices. With a response time of less than 1 ms, it can realize real – time monitoring and control, ensuring the timely response of the system to changes in the production process.

In terms of communication, it is compatible with common communication interfaces such as Ethernet/IP and DeviceNet, which is convenient for seamless integration with existing industrial networks, and can effectively improve the efficiency and accuracy of the control system. In addition, its operating temperature range is wide, and the IP20 protection level can prevent dust and other pollutants, so it can maintain stable performance in harsh environments.

Related Models

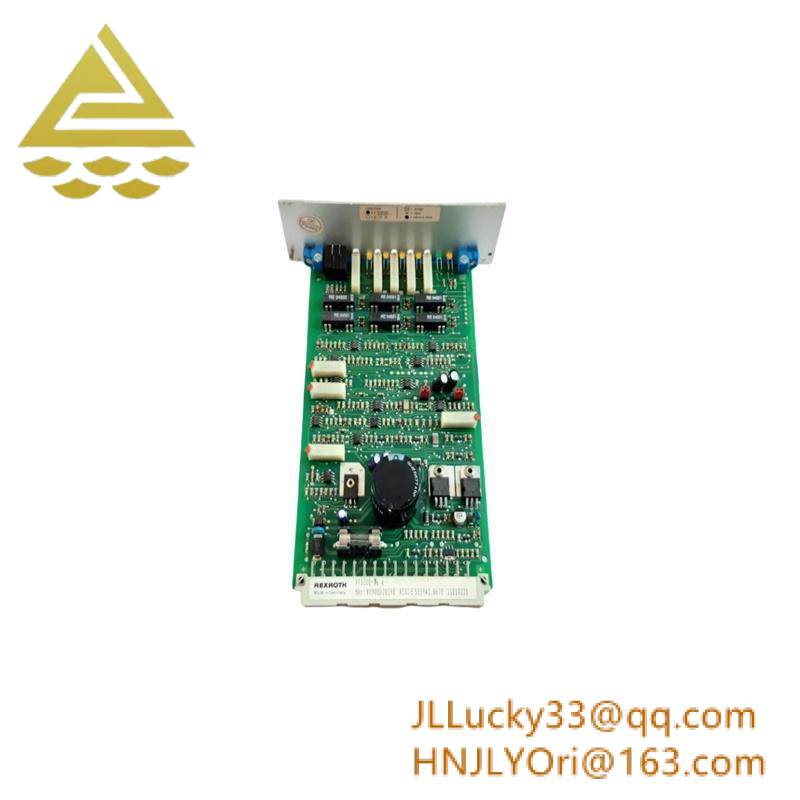

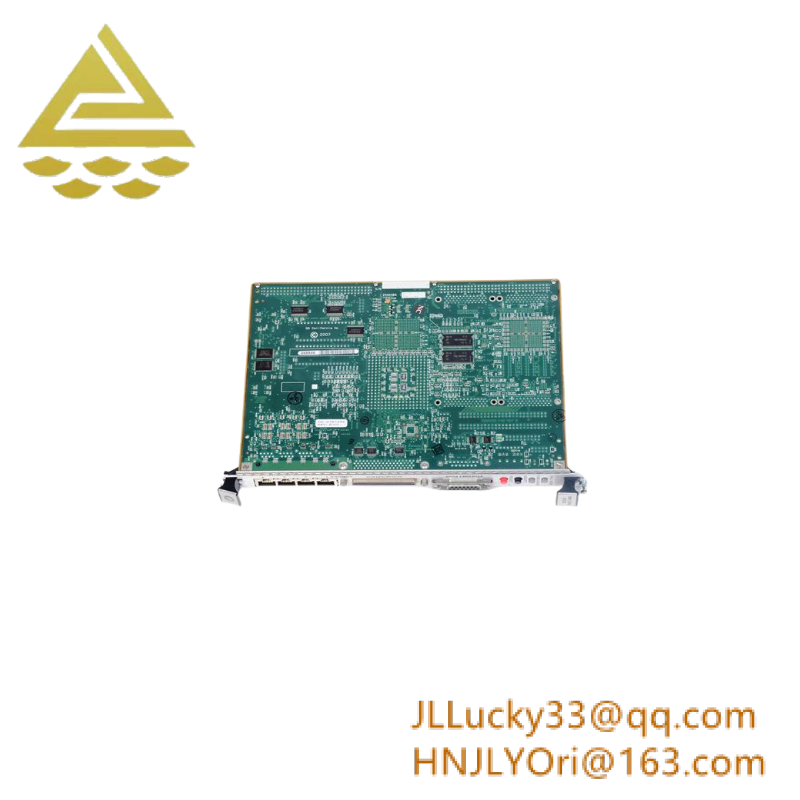

- 74102-303-51: It is a control board of Rockwell/Allen – Bradley, which supports standard GMC, GMC turbo, CNC interface, etc., and is mainly used in the 1394 digital AC multi – axis motion control system.

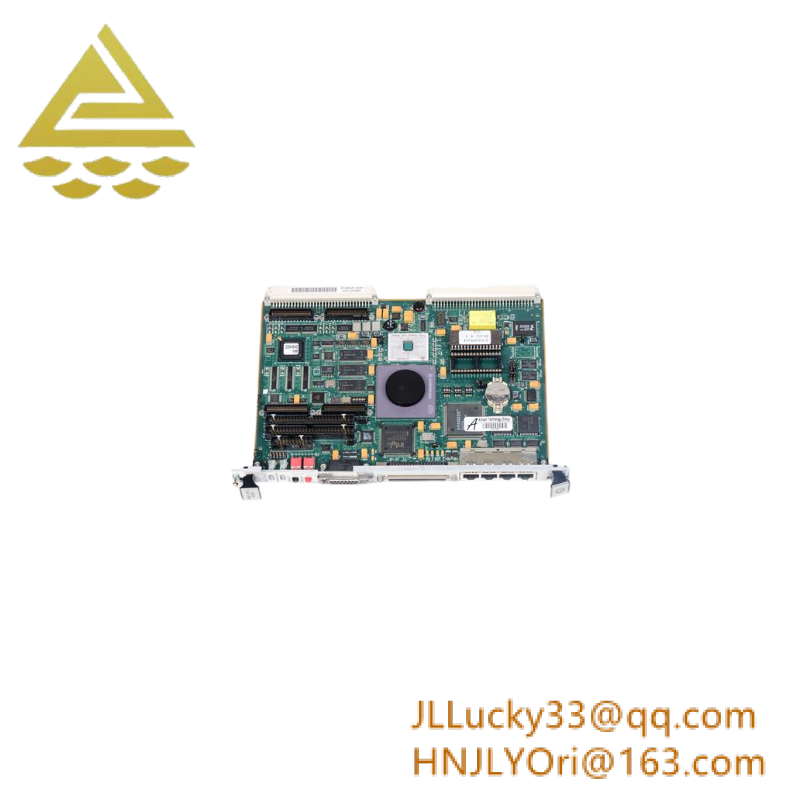

- 1756-IB16: Another digital input module of Allen – Bradley, which is also suitable for industrial automation systems, but has different technical parameters and application scenarios from 74102 – 468 – 51.

- 1746-IB16: Digital input module of Allen – Bradley, often used in SLC 500 series systems, while 74102 – 468 – 51 is more commonly used in ControlLogix systems.

- 74102-302-03A: It is a related part number of 74102 – 303 – 51, which may be a component or a variant of the same series of products.

- 1747-L532: It is the processor module of SLC 500 series. Although it is not a digital input module, it can be used in combination with 74102 – 468 – 51 in some large – scale systems.