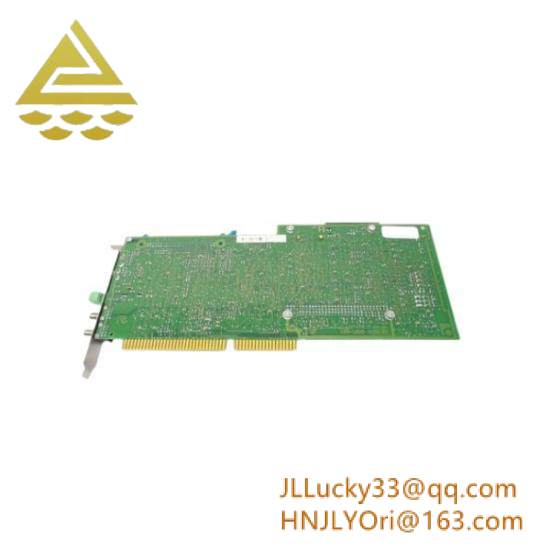

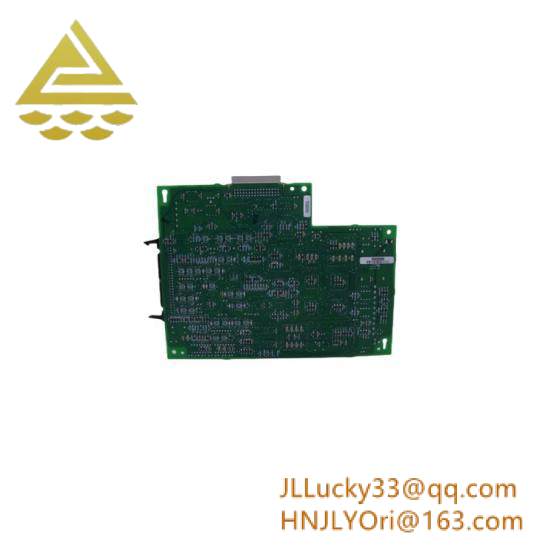

Communication Interface Module | 1771-CFM

Product Overview

The 1771-CFM is a specialized communication interface module designed to enhance data connectivity in industrial automation systems, specifically within the 1771 series PLC architectures. As a critical link between local control components and external networks, it enables efficient data transfer between PLCs, I/O modules, and supervisory systems, making it a vital component in manufacturing, logistics, and process control environments.

Key features of the 1771-CFM include multi-protocol support, ruggedized design for industrial conditions, and seamless integration with legacy 1771 series hardware. Whether deployed to connect PLCs to SCADA systems or to enable remote monitoring of distributed I/O racks, the 1771-CFM ensures stable and secure data transmission, minimizing latency and maximizing system uptime. Its compatibility with established industrial communication standards further reinforces the 1771-CFM as a reliable solution for bridging connectivity gaps in automation networks.

Technical Specifications

|

Parameter

|

Value

|

|

Product Model

|

1771-CFM

|

|

Manufacturer

|

A-B

|

|

Product Type

|

Communication Interface Module

|

|

Communication Protocols

|

ControlNet, DH+ (Data Highway Plus)

|

|

Data Transfer Rate

|

Up to 5 Mbps (ControlNet); 57.6 kbps (DH+)

|

|

Operating Voltage

|

120V AC / 240V AC (selectable)

|

|

Operating Temp

|

0°C to 60°C

|

|

Dimensions

|

4.2 x 1.6 x 8.3 inches

|

|

Mounting Type

|

1771 I/O chassis mount

|

|

Compatibility

|

1771 series PLCs, ControlNet networks

|

Key Features and Benefits

The 1771-CFM stands out for its dual-protocol support, enabling seamless communication over both ControlNet and DH+ networks. This versatility allows it to integrate with both modern and legacy systems, making it an ideal choice for facilities undergoing gradual automation upgrades. ControlNet’s high-speed (5 Mbps) data transfer ensures rapid exchange of critical process data, while DH+ compatibility maintains connectivity with older 1771 series components, preserving existing infrastructure investments.

Durability is engineered into the module, with a rugged housing and wide operating temperature range (0°C to 60°C) that withstands dust, vibration, and temperature swings common in industrial settings. This robustness ensures reliable performance in factory floors, warehouses, and outdoor installations, reducing the need for frequent maintenance.

Installation is simplified by its design for the 1771 I/O chassis, allowing for quick integration into existing systems without extensive rewiring or reconfiguration. The module’s dual-voltage input (120V AC / 240V AC) adds flexibility, supporting deployment in regions with varying electrical standards.

Another key advantage is its support for peer-to-peer communication, enabling direct data exchange between connected devices without relying on a central controller. This distributed communication model enhances system responsiveness, critical for time-sensitive applications like assembly line control or material handling.

Related Models

- 1771-CFMR – Redundant version of the 1771-CFM, featuring dual network ports for fault-tolerant communication in critical processes.

- 1771-CFME – Enhanced model with Ethernet/IP support, bridging ControlNet/DH+ networks to modern IP-based systems.

- 1771-CFMI – Isolated variant with 2500V AC channel-to-ground isolation, ideal for high-noise industrial environments.

- 1771-CFM5 – High-performance upgrade with 10 Mbps ControlNet speed, designed for large-scale networks with heavy data traffic.

- 1771-CFMD – Compact version optimized for space-constrained control cabinets, maintaining core functionality in a smaller form factor.

We provide a one-year warranty for the 1771-CFM, backed by expert pre-sales support to verify compatibility with your existing 1771 series PLCs and networks, plus responsive after-sales service for configuration and troubleshooting. Our automation specialists can assist with network setup to ensure optimal data flow, minimizing integration downtime. For more details or to inquire about other models, contact us via WhatsApp: [https://wa.me/+86 19389860630] or email: jllucky33@qq.com.