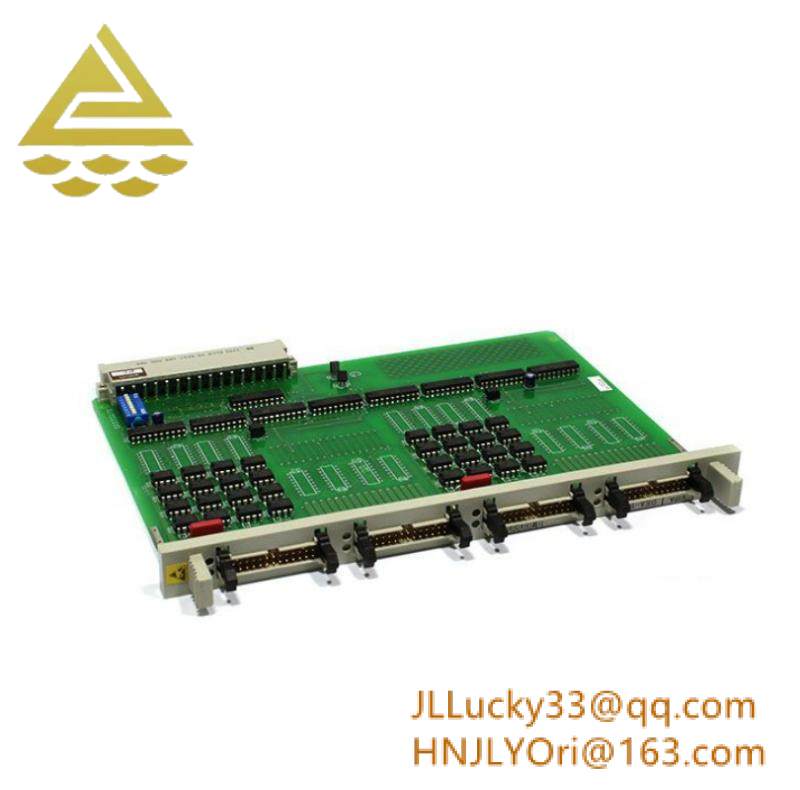

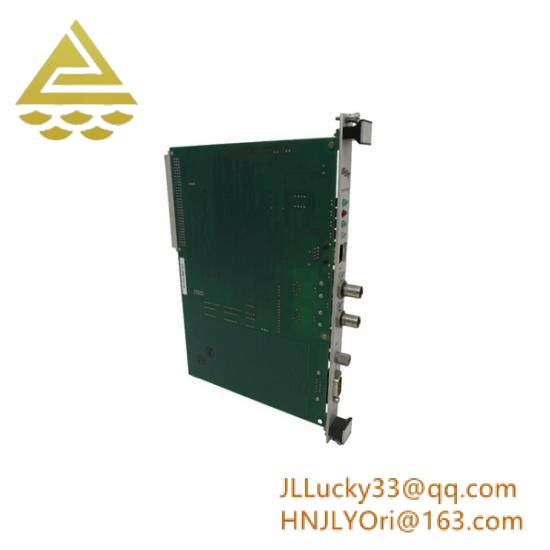

NXVFD2004A | variable frequency drive

The NXVFD2004A is a cutting-edge variable frequency drive (VFD) engineered to redefine the standards of motor control in industrial automation. As a key component within modern industrial systems, this VFD is designed to precisely regulate the speed, torque, and rotational direction of electric motors, optimizing energy consumption and enhancing equipment performance. It fits seamlessly into a wide array of automation setups, from conveyor systems in manufacturing plants to pumps and fans in HVAC systems. The NXVFD2004A stands out for its advanced control algorithms, which enable smooth operation even under fluctuating loads. By integrating this VFD into industrial processes, businesses can achieve significant cost savings through improved energy efficiency, while also extending the lifespan of connected motors. Its ability to adapt to different motor types and application requirements makes it a versatile and invaluable asset in today’s industrial landscape.

The NXVFD2004A boasts several features that give it a competitive edge in the market. Its dual control modes, V/F control and vector control, offer flexibility depending on the application. V/F control is ideal for basic speed regulation tasks, while vector control provides high-precision torque control, making it suitable for complex industrial processes. The wide frequency range of 0 – 600 Hz allows for fine-tuning of motor speeds, enabling optimal performance in various scenarios. The integrated communication protocols, such as Modbus RTU and CANopen, facilitate seamless integration with other automation devices and control systems, enabling remote monitoring and control. This enhances system management and reduces the need for on-site manual intervention.

In terms of durability, the NXVFD2004A is built to withstand the rigors of industrial environments. With an operating temperature range of -10°C to 50°C and a protection rating of IP20, it can operate reliably in a variety of settings. Additionally, its energy-saving capabilities are remarkable. By precisely controlling motor speeds based on actual load requirements, the NXVFD2004A significantly cuts down on unnecessary power consumption, leading to substantial long-term savings for businesses. Its intuitive interface also simplifies setup and operation, reducing the learning curve for operators and maintenance personnel.

Application Scenarios

The NXVFD2004A finds extensive use across multiple industries. In the manufacturing sector, it is commonly employed to control the speed of conveyor belts. For example, in a food processing plant, the NXVFD2004A can adjust the speed of conveyors carrying products for packaging, ensuring a smooth and efficient workflow while preventing damage to delicate items. In the mining industry, it powers pumps used for dewatering operations. By regulating the pump motor speed according to the water level, the VFD optimizes energy usage and extends the pump’s lifespan.

In the building services industry, the NXVFD2004A is crucial for managing HVAC systems. It controls the speed of fans and pumps, adjusting air and water flow rates based on occupancy and environmental conditions. This not only enhances indoor comfort but also achieves significant energy savings. Similarly, in the water treatment sector, the NXVFD2004A can be used to control the speed of pumps and agitators, ensuring efficient treatment processes while minimizing power consumption. Its versatility makes it a go-to solution for any application that requires precise and efficient motor control.

Related Models

- NXVFD2002A– A lower-power variant of the NXVFD2004A, with an output power of 2 kW, suitable for smaller motors and less energy-intensive applications.

- NXVFD2007A– An upgraded model offering 7 kW of output power, designed for larger motors in heavy-duty industrial settings, such as large manufacturing machinery.

- NXVFD2004B– This model features enhanced communication capabilities with additional protocols like Profibus DP, enabling better integration with more complex industrial control networks.

- NXVFD2004AH– A high-temperature-resistant version of the NXVFD2004A, with an extended operating temperature range up to 60°C, suitable for harsh environments like steel mills.

- NXVFD2004AS– It comes with a built-in solar power interface, allowing for partial operation using solar energy, making it an eco-friendly option for applications where solar power is available.

- NXVFD2004AE– This variant has improved energy-saving algorithms compared to the standard NXVFD2004A, offering even greater efficiency in power consumption.

- NXVFD2004AC– A compact version with reduced dimensions, ideal for installations where space is limited, such as in small control cabinets.

- NXVFD2004AF– It includes advanced fault prediction features, enabling proactive maintenance and reducing the risk of unexpected system breakdowns.

- NXVFD2004AG– The model is equipped with a higher protection rating of IP21, providing better defense against dust and water ingress in outdoor or dusty indoor applications.

| GE | 05060103T1AR20 |

| GE | DS380ONPPBILIH |

| GE | DS3800NPSJ1B1B |

| GE | DS3820PSCC1 |

| GE | DS3820DMCB1 |

| GE | DS3820DMVB1 |