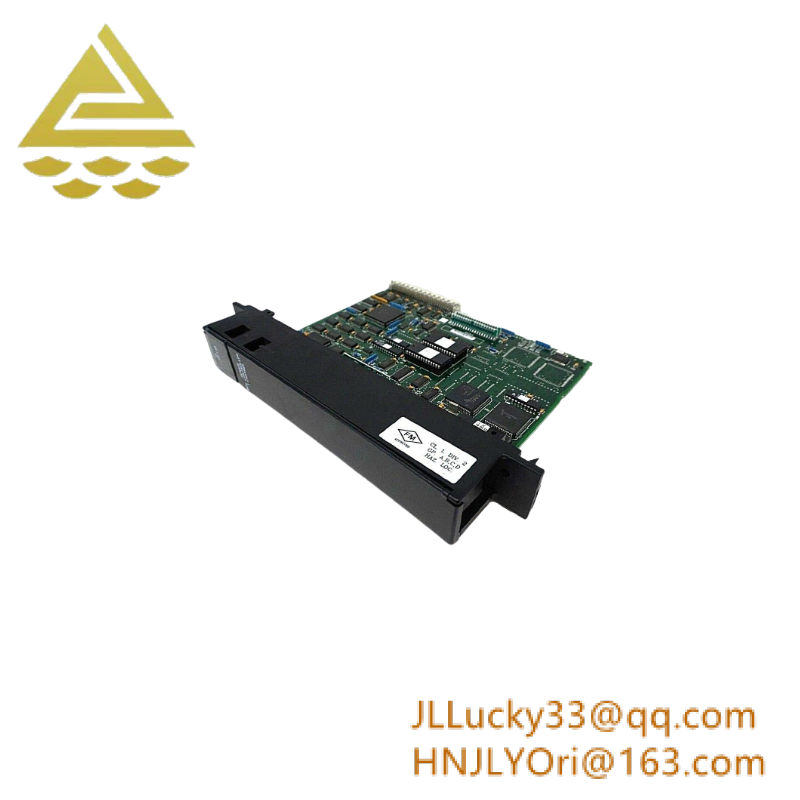

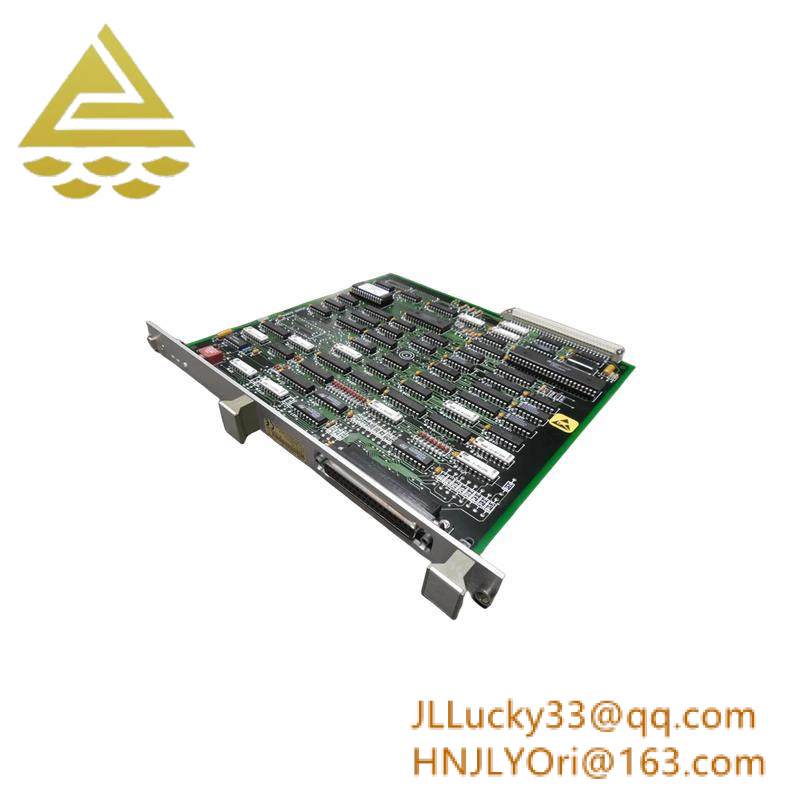

Product Overview

The 2190-BKC-48M-86TCCXC is a high-performance servo drive from Allen-Bradley’s Kinetix 5700 series, engineered to deliver precise motion control in demanding industrial applications. This drive is designed to work seamlessly with servo motors, providing exceptional speed and position accuracy, which is crucial for automated manufacturing processes. The 2190-BKC-48M-86TCCXC stands out for its advanced control algorithms, robust build quality, and integration capabilities with modern industrial networks. Its compact design allows for efficient use of cabinet space, while its ability to handle dynamic loads ensures reliable performance in applications such as robotic arms, precision assembly lines, and CNC machinery. Whether in the automotive, electronics, or aerospace industry, the 2190-BKC-48M-86TCCXC plays a vital role in enhancing production efficiency and product quality.

Technical Specifications

|

Parameter

|

Value

|

|

Product Model

|

2190-BKC-48M-86TCCXC

|

|

Manufacturer

|

Allen-Bradley

|

|

Product Type

|

Servo Drive

|

|

Input Voltage

|

3-phase, 400 – 480 VAC

|

|

Continuous Output Current

|

48 A

|

|

Peak Output Current

|

144 A (for 3 seconds)

|

|

Control Modes

|

Position, Velocity, Torque

|

|

Communication Protocol

|

EtherNet/IP

|

|

Operating Temperature

|

0 – 55 °C

|

|

Mounting Type

|

Chassis-mountable

|

|

IP Rating

|

IP20 (suitable for control cabinet installation)

|

Key Features and Benefits

Ultra-Precise Motion Control

The 2190-BKC-48M-86TCCXC leverages advanced servo control algorithms to achieve micron-level position accuracy and smooth velocity regulation. This precision is essential in applications like semiconductor wafer handling, where even the smallest deviation can compromise product integrity. The drive’s ability to maintain tight control over motor movement ensures consistent product quality and reduces waste in high-precision manufacturing processes.

High Dynamic Response

With a high peak current capability of 144 A, the 2190-BKC-48M-86TCCXC can quickly accelerate and decelerate servo motors, making it ideal for applications with rapid start-stop cycles. For example, in packaging machinery, this feature allows for faster throughput without sacrificing accuracy, as the drive can adjust motor speed in real-time to match varying production demands.

Seamless Network Integration

Equipped with EtherNet/IP communication, the 2190-BKC-48M-86TCCXC integrates effortlessly with industrial control systems, HMIs, and other smart devices. This connectivity enables real-time data exchange, allowing operators to monitor drive performance, adjust parameters remotely, and diagnose issues without physical access to the cabinet. It also supports synchronization with multiple drives in a system, ensuring coordinated motion in complex applications like robotic assembly cells.

Robust Protection and Diagnostics

The 2190-BKC-48M-86TCCXC includes a comprehensive suite of protection features, such as overcurrent, overvoltage, undervoltage, overtemperature, and short-circuit protection. These safeguards prevent damage to the drive and connected motors in case of electrical faults or abnormal operating conditions. Additionally, advanced diagnostic tools provide detailed fault codes and performance data, enabling maintenance teams to quickly identify and resolve issues, minimizing downtime.

Energy Efficiency

Designed with energy-saving features, the 2190-BKC-48M-86TCCXC optimizes power consumption by adjusting output voltage and current based on motor load. This efficiency not only reduces operational costs but also lowers heat generation, extending the lifespan of the drive and contributing to a more sustainable manufacturing environment.

Related Models

- 2190-BKC-32M-86TCCXC – A lower-current variant of the 2190-BKC-48M-86TCCXC with a 32 A continuous output, suitable for smaller servo motors in light to medium-duty applications.

- 2190-BKC-64M-86TCCXC – A higher-current model with a 64 A continuous output, designed for larger servo motors in heavy-duty motion control systems.

- 2190-BKL-48M-86TCCXC – A variant of the 2190-BKC-48M-86TCCXC with enhanced safety features, including STO (Safe Torque Off), for applications requiring functional safety compliance.

- 2190-BKC-48M-86TCCXCB – A base model of the 2190-BKC-48M-86TCCXC without advanced network features, offering a cost-effective solution for simple motion control tasks.

- 2190-PS150 – A power supply module compatible with the 2190-BKC-48M-86TCCXC, providing stable DC power to the drive in multi-drive systems.

- MPL-B4530F-MJ74AA – A servo motor designed to work seamlessly with the 2190-BKC-48M-86TCCXC, offering high torque and precision for synchronized motion applications.

- 2190-DNET – A DeviceNet communication adapter for the 2190-BKC-48M-86TCCXC, enabling integration with legacy DeviceNet networks.

We provide the 2190-BKC-48M-86TCCXC with a one-year warranty, ensuring reliable performance and peace of mind. Our pre-sales team offers expert advice to help you select the right servo drive and motor combination for your specific application, ensuring optimal performance and compatibility. Post-purchase, our technical support specialists are available to assist with installation, programming, and troubleshooting, helping to minimize downtime and maximize productivity. If you require a model not listed here, please contact us immediately—we are dedicated to meeting all your industrial automation needs with professionalism and efficiency.