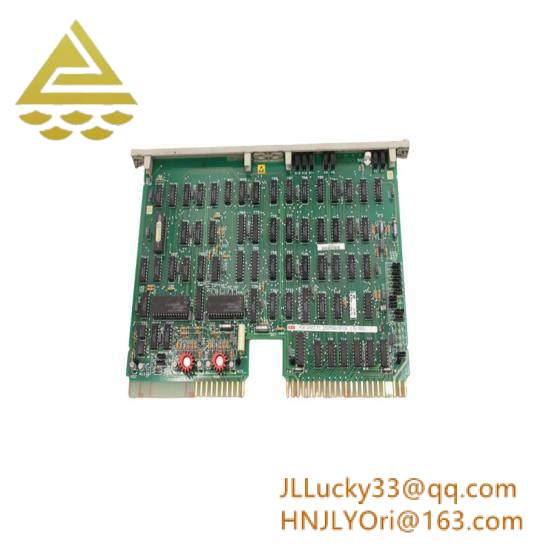

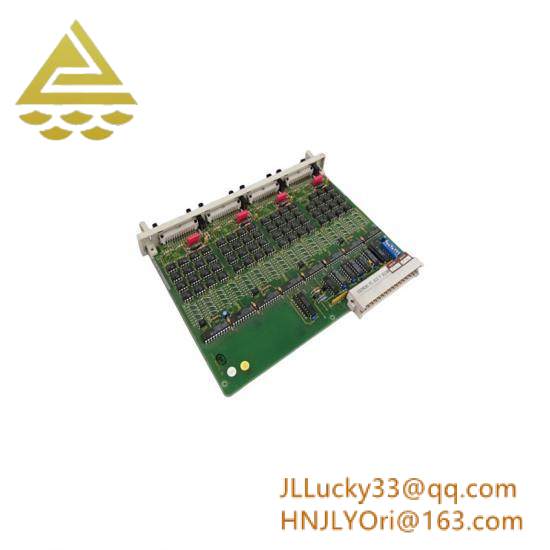

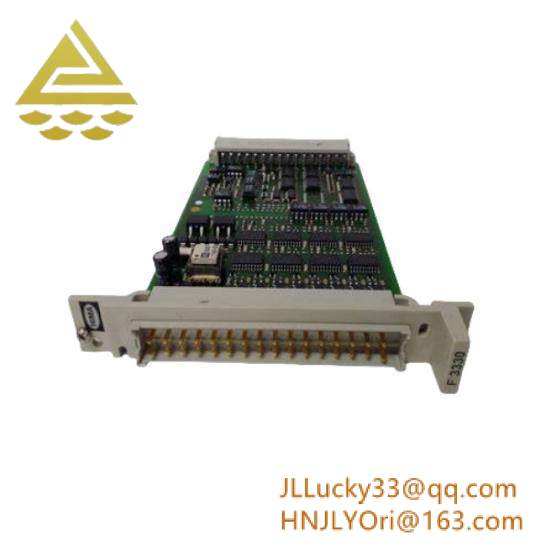

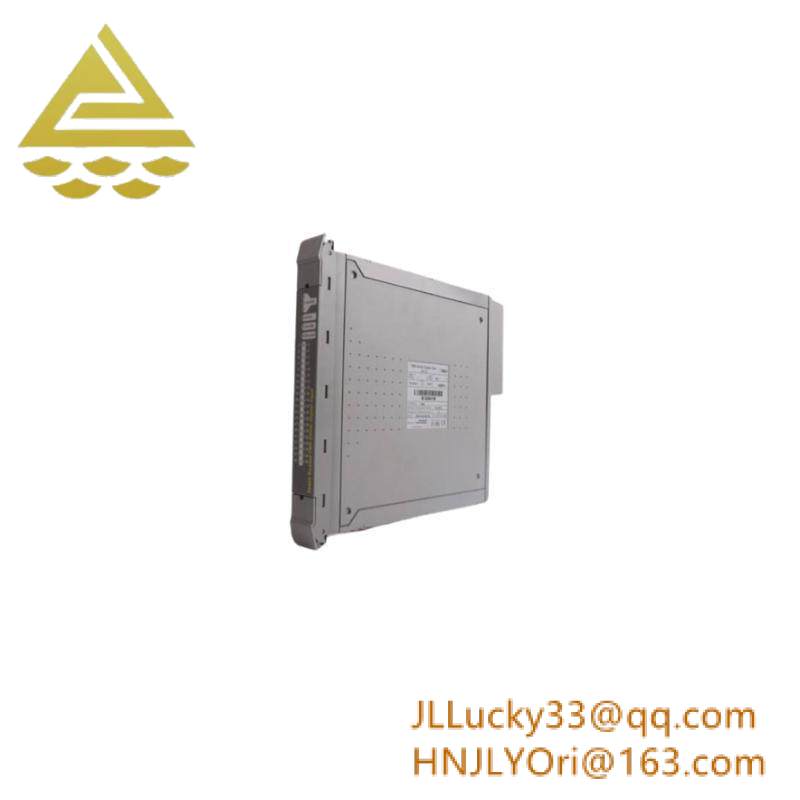

GATS110143R0002 Industrial Ethernet Transceiver Module

Product Overview

The GATS110143R0002 is a high-performance industrial transceiver module, specifically designed to facilitate reliable data communication in harsh industrial environments. Developed by a leading manufacturer of industrial networking solutions, this module serves as a critical link in automation networks, enabling seamless data transmission between PLCs, sensors, actuators, and control systems. Whether deployed in manufacturing plants, oil and gas facilities, or power generation sites, the GATS110143R0002 excels in maintaining stable communication even in the presence of electromagnetic interference (EMI), vibration, or extreme temperature fluctuations. Its rugged construction and advanced signal processing capabilities make the GATS110143R0002 a trusted component for ensuring uninterrupted data flow in mission-critical industrial networks.

Technical Specifications

|

Parameter

|

Value

|

|

Product Model

|

GATS110143R0002

|

|

Manufacturer

|

ABB

|

|

Product Type

|

Industrial Ethernet Transceiver Module

|

|

Communication Protocol

|

Ethernet/IP, Modbus TCP

|

|

Data Transfer Rate

|

10/100 Mbps (auto-negotiation)

|

|

Input Voltage

|

24V DC ±15%

|

|

Operating Temperature

|

-40°C to 85°C

|

|

Protection Rating

|

IP67 (when mated with compatible connector)

|

|

Connection Type

|

M12 circular connector (D-coded)

|

|

Mounting Type

|

Din rail or panel mount

|

Key Features and Benefits

The GATS110143R0002 stands out for its exceptional reliability and adaptability in challenging industrial communication environments. Its support for Ethernet/IP and Modbus TCP protocols ensures seamless integration with a wide range of industrial automation systems, from legacy setups to modern smart factories, eliminating compatibility issues and simplifying network expansion.

With a data transfer rate of 10/100 Mbps and auto-negotiation capabilities, the module efficiently handles both small control signals and large data packets, making it suitable for applications ranging from real-time sensor monitoring to video surveillance of production lines. This versatility reduces the need for multiple specialized transceivers, streamlining network design and reducing costs.

Ruggedness is a defining feature: the IP67 protection rating (when properly connected) shields the module from dust, water immersion, and chemical exposure, making it ideal for outdoor installations or washdown areas in food and beverage plants. The wide operating temperature range (-40°C to 85°C) ensures reliable performance in extreme conditions, from frozen storage facilities to desert-based solar farms.

Advanced EMI resistance ensures stable communication in environments with high electrical noise, such as near motors, transformers, or welding equipment, preventing data loss or corruption that could lead to operational disruptions. The M12 D-coded connector provides a secure, vibration-resistant connection, minimizing the risk of accidental disconnections in high-motion applications like conveyor systems.

Backed by a one-year warranty and expert technical support, the GATS110143R0002 offers a cost-effective solution for building robust, future-proof industrial networks.

Related Models

- GATS110142R0001 – 10 Mbps fixed-speed variant, suitable for legacy systems with lower bandwidth requirements.

- GATS110144R0003 – Gigabit Ethernet (1000 Mbps) model, designed for high-bandwidth applications like 4K video streaming or large-scale IoT deployments.

- GATS110143R0004 – Fiber optic version, offering extended transmission distance (up to 2 km) and immunity to electrical interference for long-haul industrial networks.

- GATS110143R0005 – PoE (Power over Ethernet) enabled module, eliminating the need for separate power cables in remote sensor installations.

- GATS110145R0006 – Redundant port model, featuring two independent Ethernet ports for fail-safe communication in mission-critical systems.

We are a certified distributor of industrial control products, offering expert pre-sales consultation and reliable after-sales support. All products come with a one-year warranty. If you need further assistance or cannot find the model you require, please contact us via WhatsApp: [https://wa.me/+86 19389860630] or email: jllucky33@qq.com.