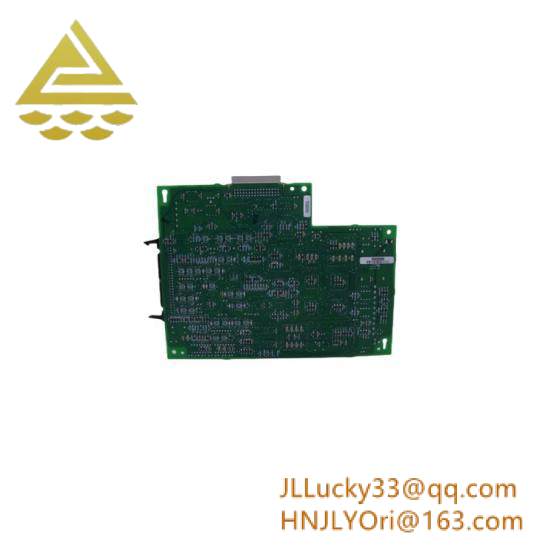

versatile communication module | 1771-ACN

Product Overview

The 1771-ACN is a versatile communication module designed to facilitate seamless data exchange in industrial automation systems, particularly within PLC-based control architectures. As a critical networking component, it enables reliable connectivity between local I/O modules and remote control systems, making it indispensable in industries such as manufacturing, material handling, and industrial processing.

Key features of the 1771-ACN include high-speed data transmission, robust protocol support, and durable construction tailored for harsh industrial environments. Whether deployed to link distributed I/O racks in a factory or to integrate legacy equipment with modern control systems, the 1771-ACN ensures consistent and secure communication, enhancing system efficiency and reducing operational bottlenecks. Its compatibility with established industrial protocols further solidifies the 1771-ACN as a trusted solution for bridging gaps in automation networks.

Technical Specifications

|

Parameter

|

Value

|

|

Product Model

|

1771-ACN

|

|

Manufacturer

|

A-B

|

|

Product Type

|

Industrial Communication Module

|

|

Communication Protocol

|

DH+ (Data Highway Plus)

|

|

Data Transfer Rate

|

57.6 kbps

|

|

Operating Voltage

|

120V AC / 240V AC (selectable)

|

|

Operating Temp

|

0°C to 60°C

|

|

Dimensions

|

4.2 x 1.6 x 8.3 inches

|

|

Mounting Type

|

1771 I/O chassis mount

|

|

Compatibility

|

1771 series PLC systems

|

Key Features and Benefits

The 1771-ACN excels in enabling efficient data communication across industrial networks, thanks to its support for the DH+ protocol—a proven standard in industrial automation for reliable, peer-to-peer data exchange. This allows the module to seamlessly connect I/O modules, PLCs, and operator interfaces, ensuring real-time data flow critical for process monitoring and control.

Durability is a standout feature, with the 1771-ACN built to withstand the rigors of industrial environments. Its wide operating temperature range (0°C to 60°C) and robust housing protect against dust, vibration, and temperature fluctuations, ensuring consistent performance in factory floors and outdoor installations alike.

Installation and integration are streamlined by its design for the 1771 I/O chassis, making it easy to add to existing systems without extensive reconfiguration. This compatibility with legacy 1771 series components reduces upgrade costs, allowing facilities to modernize their communication infrastructure while retaining reliable older equipment.

The module’s dual-voltage input (120V AC / 240V AC) adds flexibility, enabling deployment in regions with different electrical standards. Additionally, its compact size optimizes space within control cabinets, a valuable attribute in crowded industrial setups.

Related Models

- 1771-ACNR – Redundant version of the 1771-ACN, featuring dual communication paths for enhanced system reliability in critical applications.

- 1771-ACD – DH-485 protocol variant, suitable for smaller-scale networks requiring lower data transfer rates.

- 1771-ACNI – Isolated version with enhanced electrical isolation (2500V AC), ideal for noisy industrial environments with high electromagnetic interference.

- 1771-ACNW – Wireless-enabled model, eliminating the need for physical cabling in hard-to-reach or mobile applications.

- 1771-ACN15 – High-speed upgrade with a 125 kbps data transfer rate, designed for networks with increased data volume.

We offer a one-year warranty for the 1771-ACN, backed by expert pre-sales consultation to ensure compatibility with your existing PLC systems and responsive after-sales support for troubleshooting. Our automation specialists can assist with setup and network configuration, minimizing downtime during integration. For more details or to inquire about other models, contact us via WhatsApp: [https://wa.me/+86 19389860630] or email: jllucky33@qq.com.