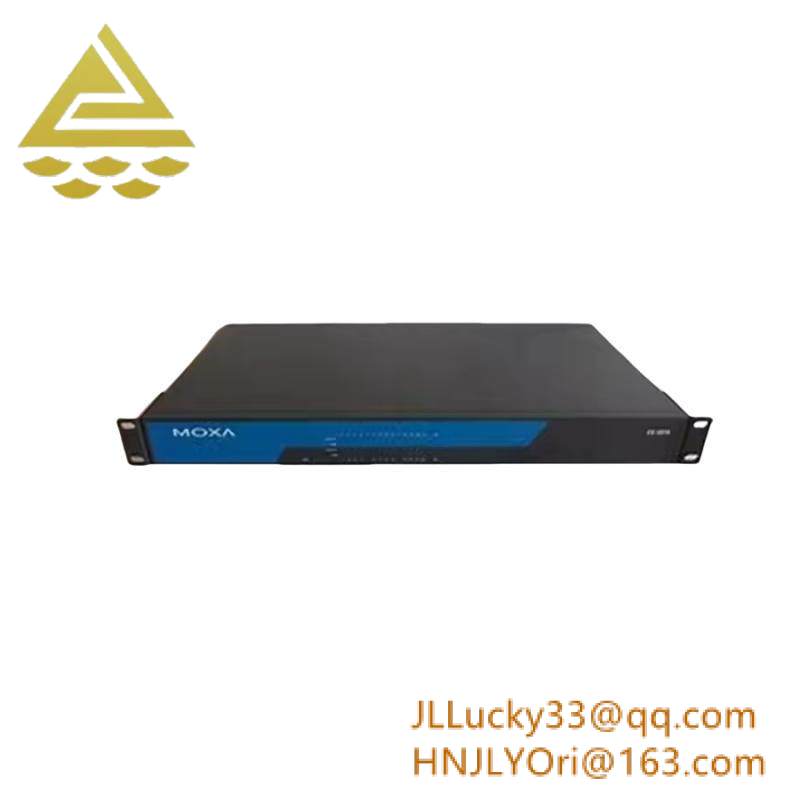

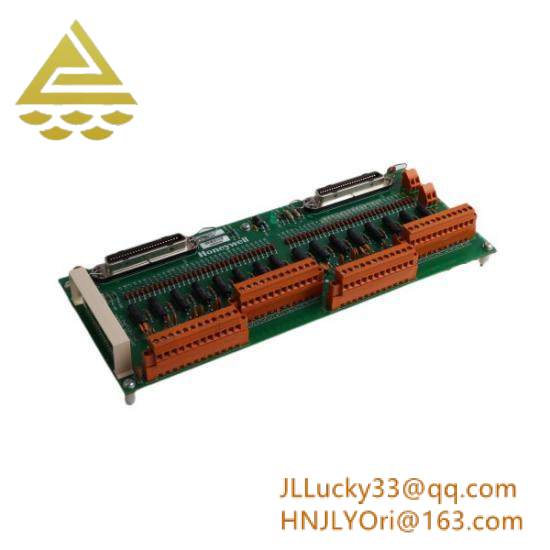

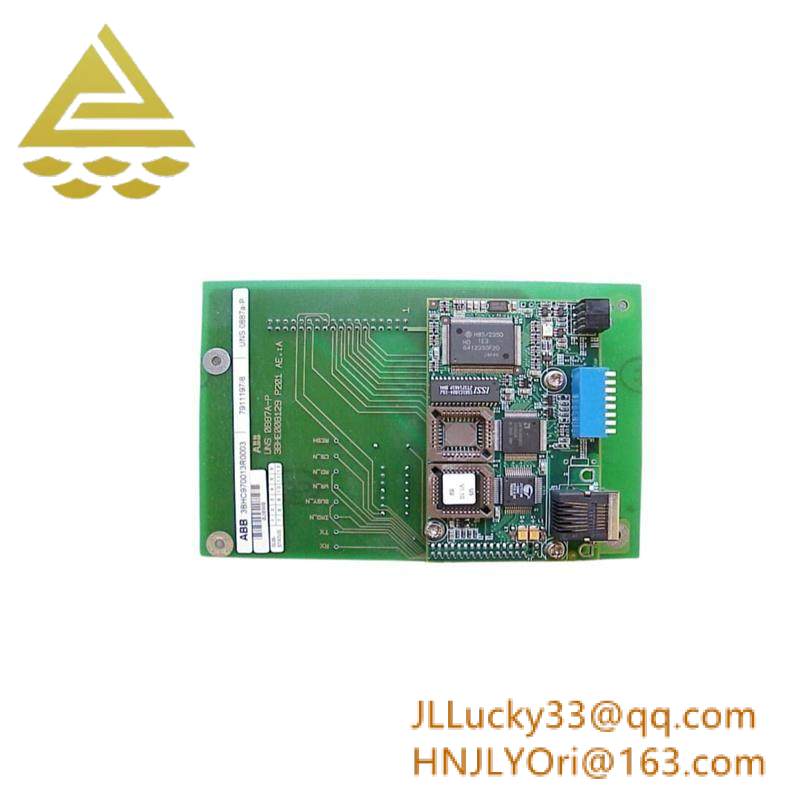

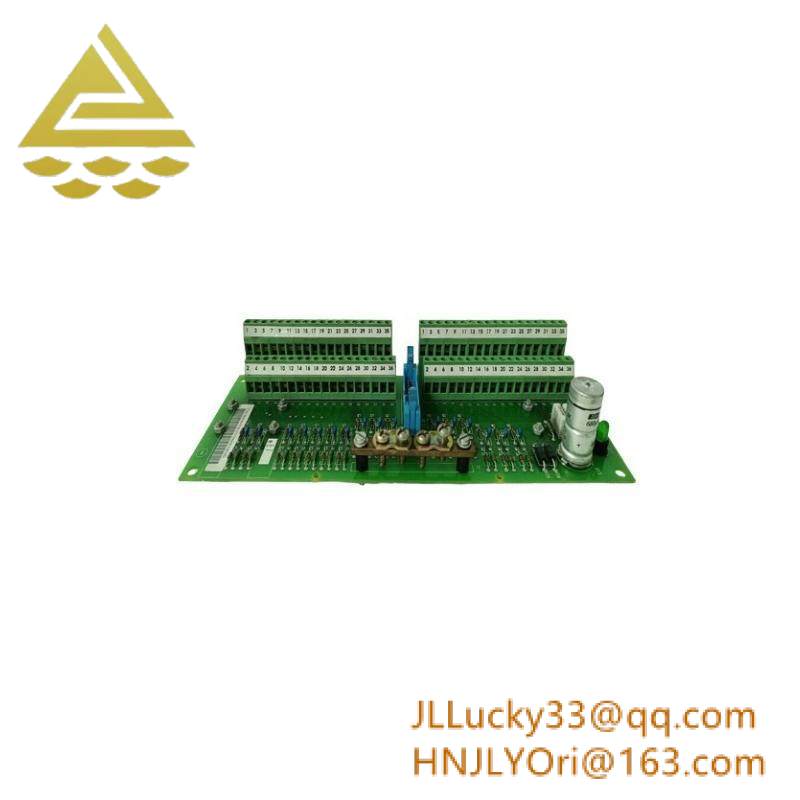

GIDDINGS AND LEWIS INPUT MODULE 502 – 03840 – 20 | Input Module

Product Overview

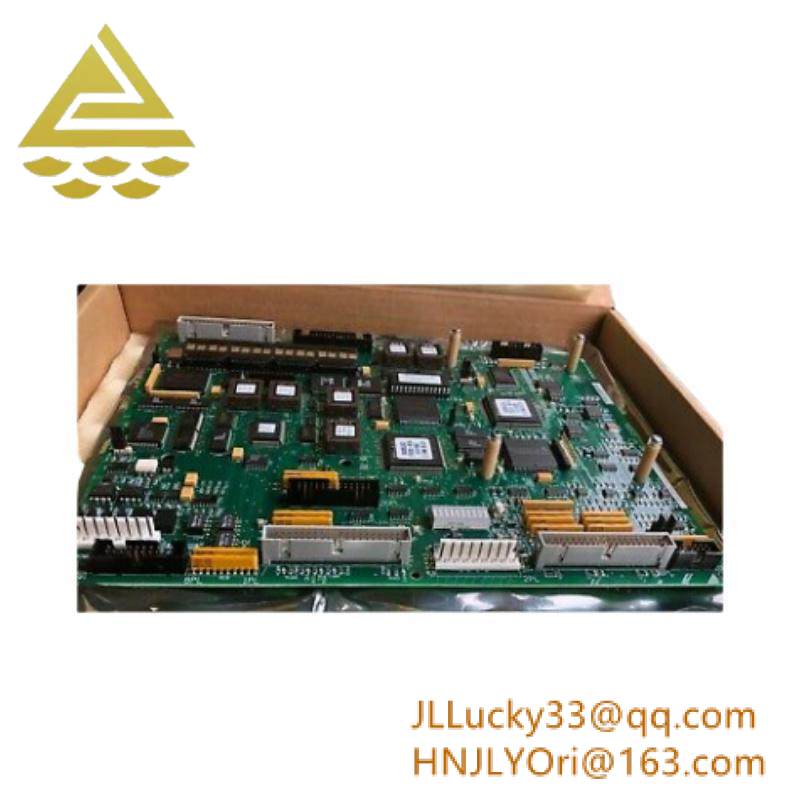

The GIDDINGS AND LEWIS INPUT MODULE 502 – 03840 – 20 is a pivotal component within the industrial control infrastructure, specifically designed to interface with various sensors and transducers in industrial automation setups. As part of GIDDINGS AND LEWIS’ comprehensive range of industrial control products, this input module plays a crucial role in the data acquisition process.

Within the context of industrial systems, the GIDDINGS AND LEWIS INPUT MODULE 502 – 03840 – 20 serves as the bridge between the physical world of sensors and the digital control systems. It is engineered to accurately receive and convert a variety of input signals, such as those from proximity sensors, temperature sensors, and pressure sensors, into a format that can be easily processed by the central control unit. This module is often deployed in industrial environments like manufacturing plants, where it contributes to the seamless operation of automated production lines by ensuring that real – time data from the factory floor is efficiently fed into the control system. Its significance lies in its ability to enhance the overall reliability and precision of industrial processes, as accurate input data is the foundation for making informed control decisions. Hainan Jinlin Electromechanical, with its wealth of experience in distributing industrial control products, is well – equipped to provide this high – quality input module to meet your industrial requirements.

Key Features and Benefits

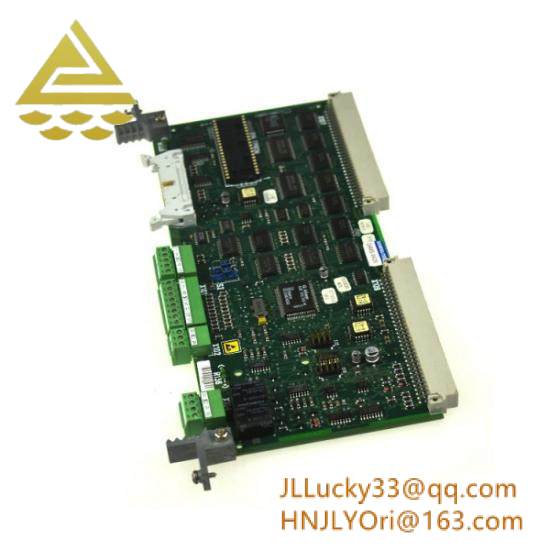

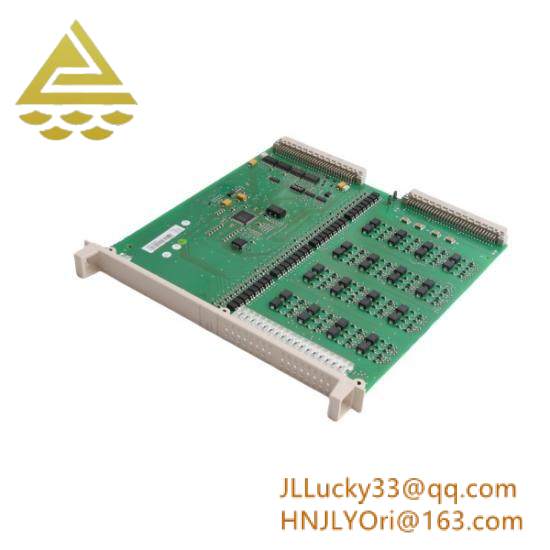

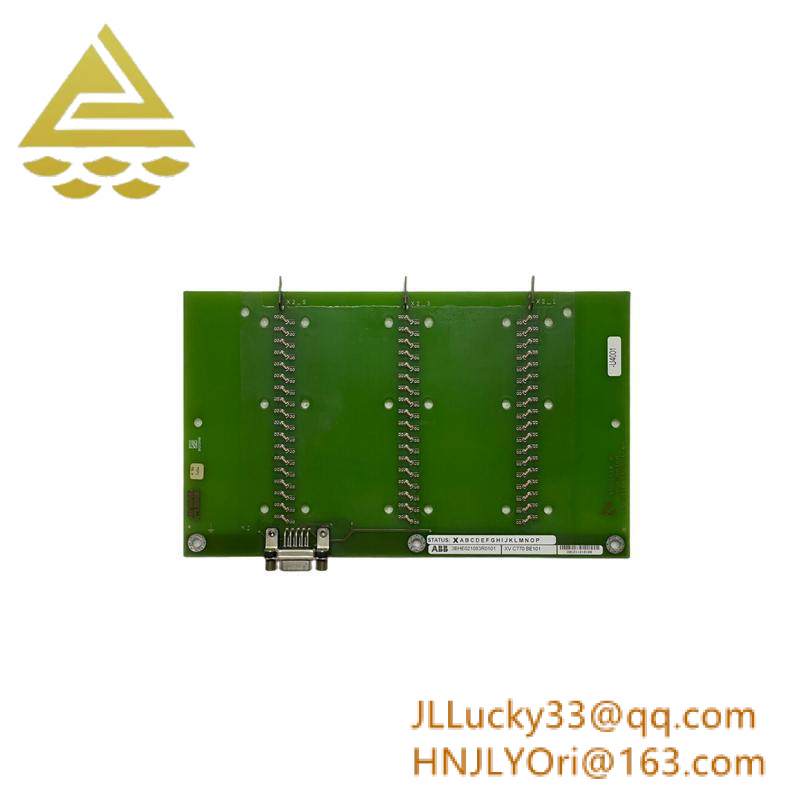

The GIDDINGS AND LEWIS INPUT MODULE 502 – 03840 – 20 comes with several key features that make it stand out in the industrial control market. Its wide – ranging input signal compatibility is a major advantage. By being able to handle both digital and analog signals, it can interface with a diverse array of sensors, providing flexibility in system design. This means that in an industrial setting where multiple types of sensors are used for different monitoring purposes, the GIDDINGS AND LEWIS INPUT MODULE 502 – 03840 – 20 can be a single – stop solution for signal acquisition.

The module also features high – quality signal isolation. Optical isolation, for example, effectively protects the module and the connected control system from electrical interference, such as voltage spikes and electromagnetic noise. This is crucial in industrial environments, where electrical disturbances are common. By maintaining signal integrity, the module ensures that the data fed into the control system is accurate, reducing the likelihood of incorrect control actions due to noisy input signals.

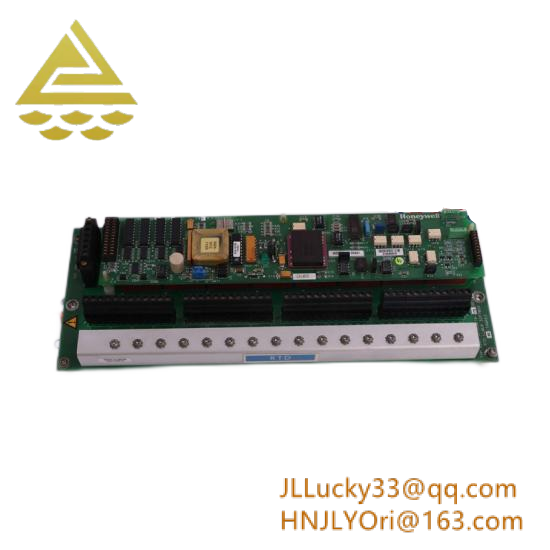

The number of input channels, say 16, allows for the connection of multiple sensors simultaneously. This is beneficial in large – scale industrial applications where comprehensive monitoring of different parameters at various points in the production process is required. It simplifies the wiring and installation process, as fewer modules may be needed to achieve the desired sensor coverage. Additionally, Hainan Jinlin Electromechanical offers professional pre – sales support to help you configure the module according to your specific application needs and provides a one – year after – sale guarantee, ensuring the long – term performance and reliability of the GIDDINGS AND LEWIS INPUT MODULE 502 – 03840 – 20.

Related Models

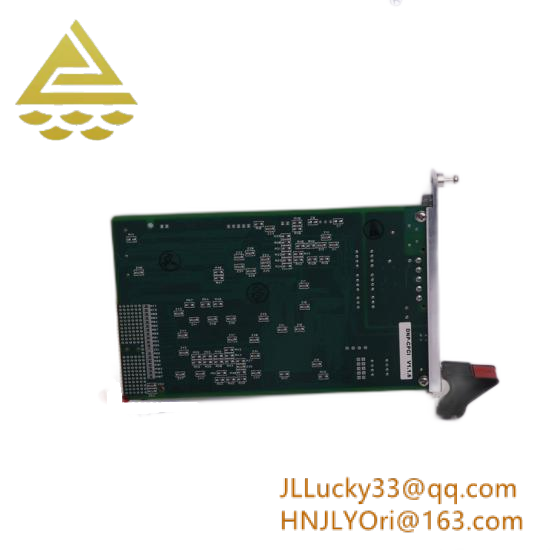

- GIDDINGS AND LEWIS 502 – 03548 – 00R4 – Another input module that may have different input channel configurations or signal handling capabilities. It could be used in applications where a different number of sensors or specific signal types need to be accommodated compared to the GIDDINGS AND LEWIS INPUT MODULE 502 – 03840 – 20.

- GIDDINGS AND LEWIS 502 – 03840 – 23R2 – A servo encoder module within the same product family. While it has a different primary function related to servo encoding, it may share some common interface or power supply characteristics with the GIDDINGS AND LEWIS INPUT MODULE 502 – 03840 – 20 and can be used in complementary roles within a complex industrial control system.

- GIDDINGS AND LEWIS 502 – 03840 – 24R0 – Similar to the 502 – 03840 – 23R2, it is a servo module encoder. It might offer different levels of performance or feature sets, such as a different number of analog output channels or encoder input channels, which could be relevant depending on the requirements of the overall motion and control system in which the GIDDINGS AND LEWIS INPUT MODULE 502 – 03840 – 20 is also deployed.

- GIDDINGS AND LEWIS 502 – 03862 – 00 – Although details about its exact function are not fully clear from the given information, it is likely an industrial control – related module from GIDDINGS AND LEWIS. It could potentially be used in combination with the GIDDINGS AND LEWIS INPUT MODULE 502 – 03840 – 20 in a system – level integration, perhaps for additional control or signal conditioning purposes.

- GIDDINGS AND LEWIS 502 – 03781 – 00 – Another module within the GIDDINGS AND LEWIS product line. It may have a role in the overall industrial control setup, such as being part of a communication or power management subsystem that interfaces with the GIDDINGS AND LEWIS INPUT MODULE 502 – 03840 – 20 to ensure the smooth operation of the entire industrial automation system.

If you are interested in the GIDDINGS AND LEWIS INPUT MODULE 502 – 03840 – 20 or any of the related models, or if you are unable to find the exact product you need, please do not hesitate to contact Hainan Jinlin Electromechanical. You can reach out via WhatsApp or send an email to jllucky33@qq.com. Their team of experts is dedicated to assisting you with all your industrial control product inquiries.