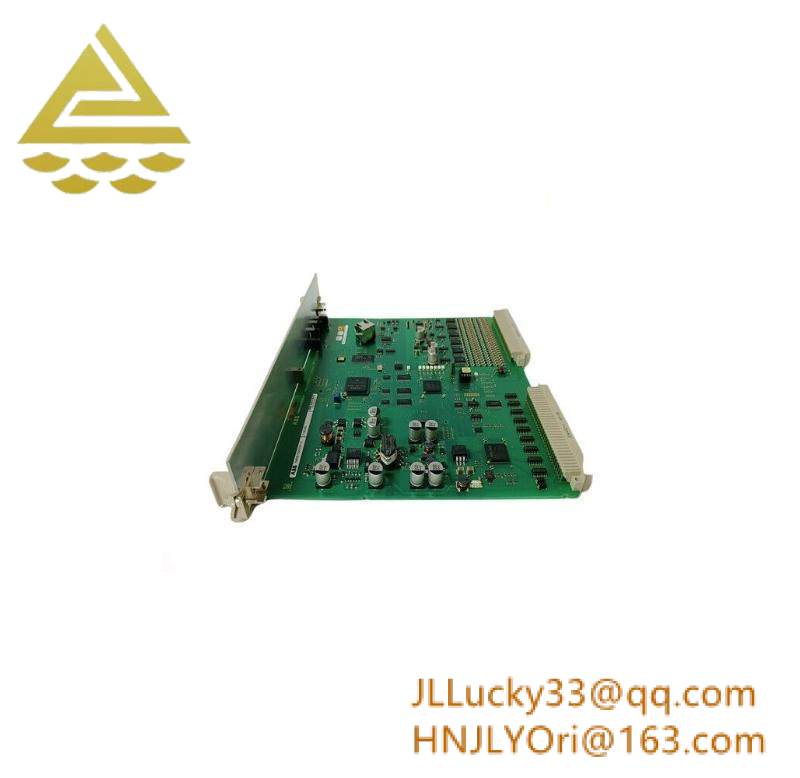

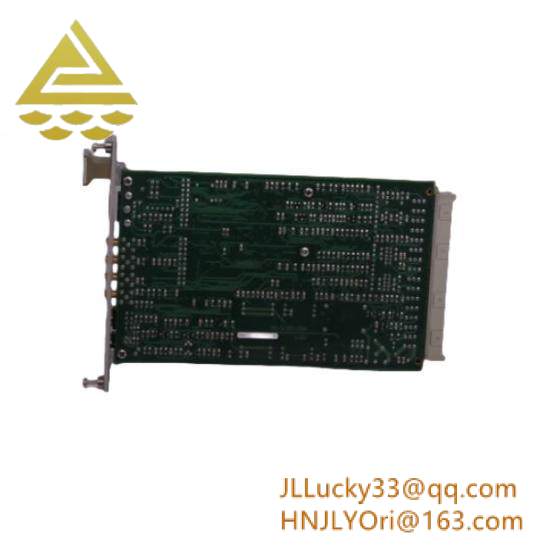

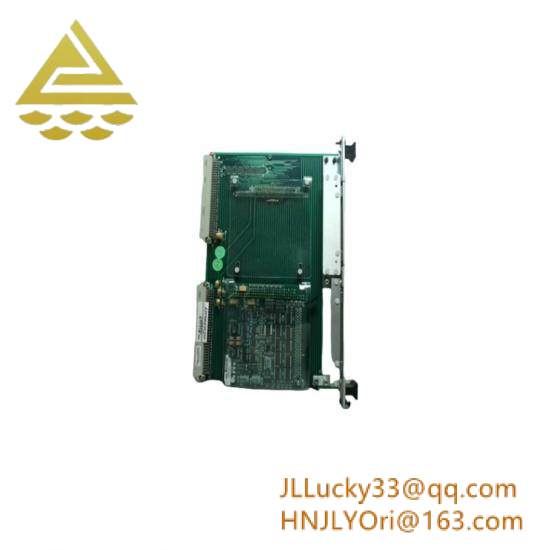

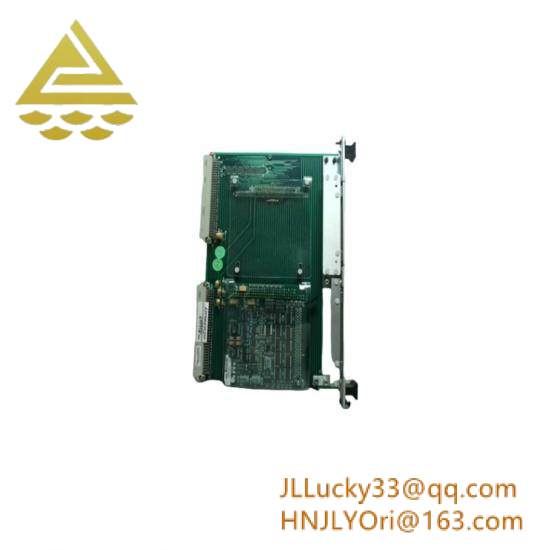

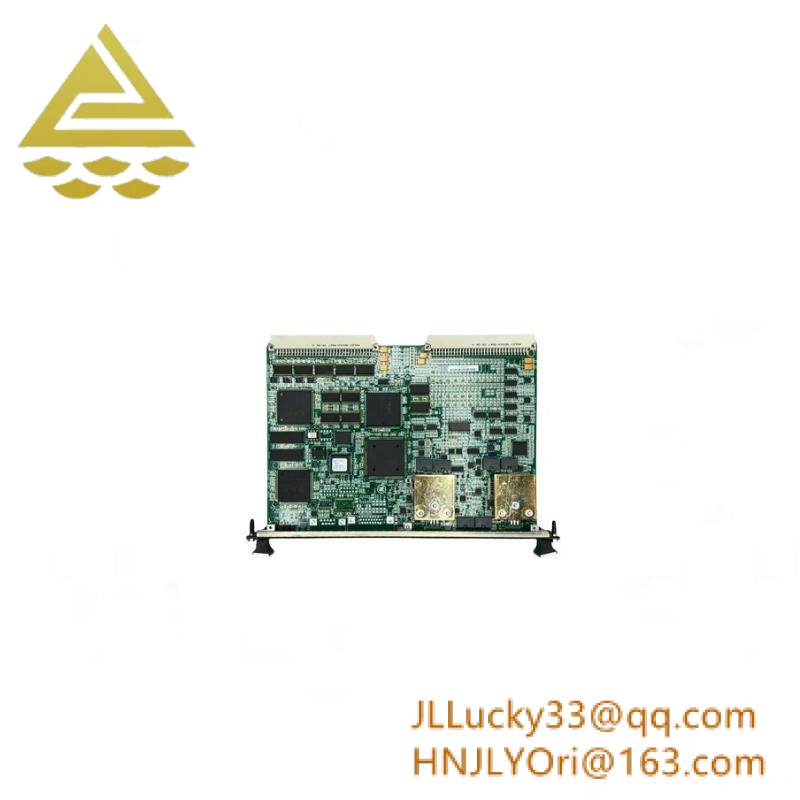

EtherCAT communication module | DELTA TAU ACC-36E

Product Overview

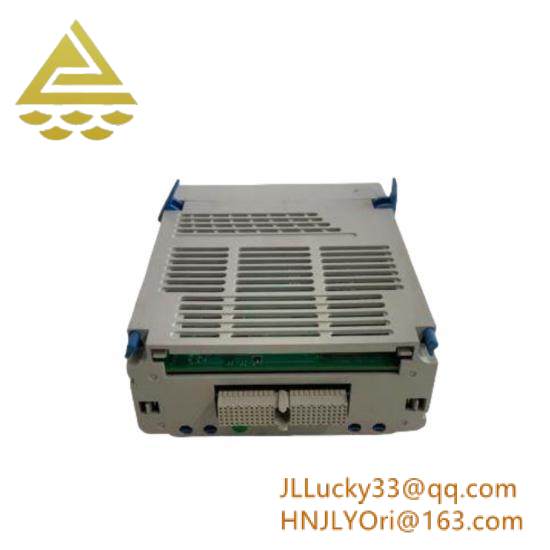

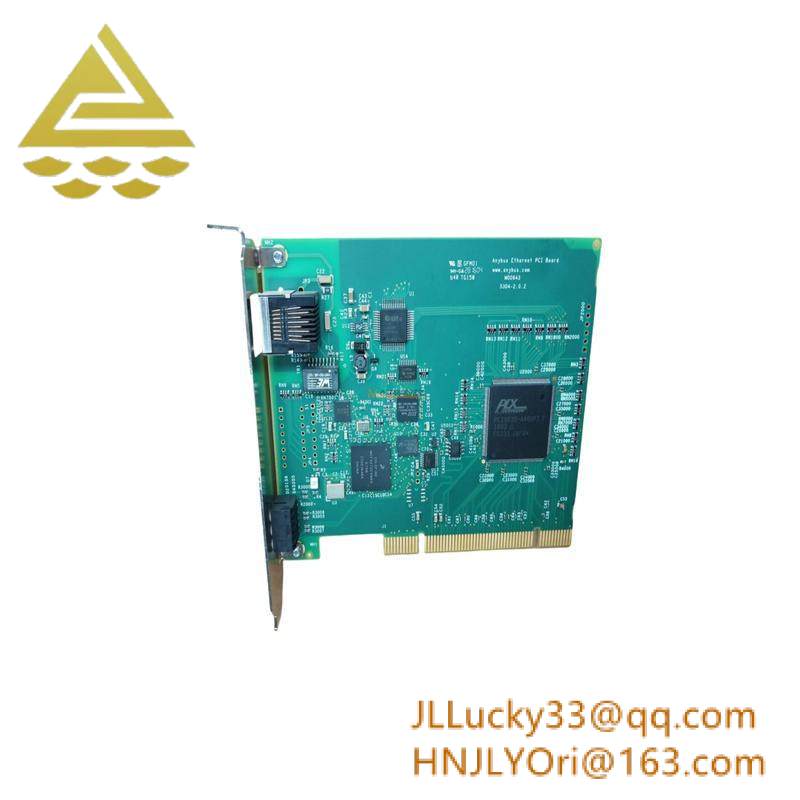

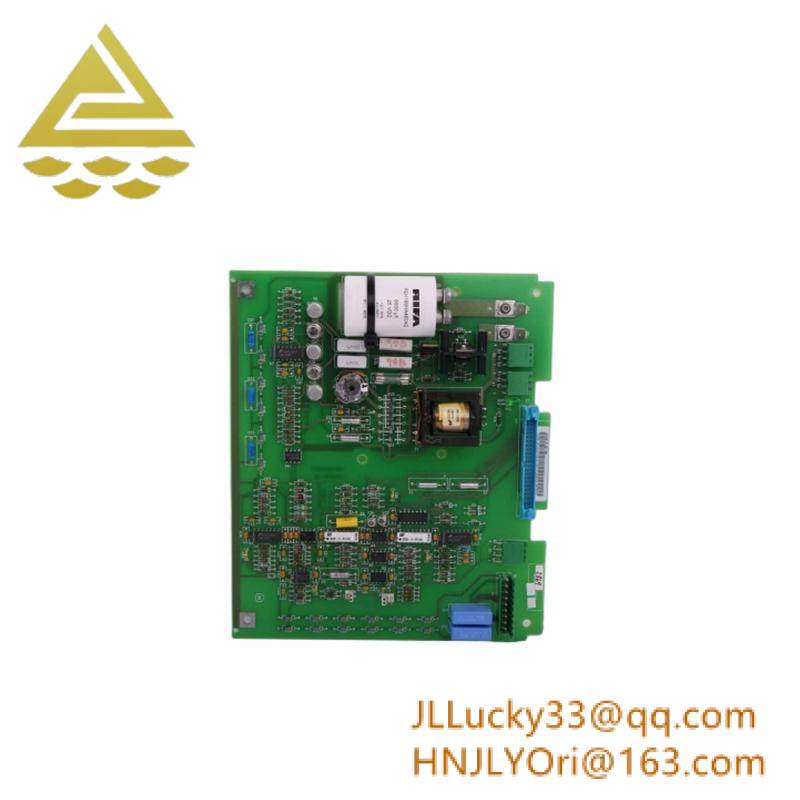

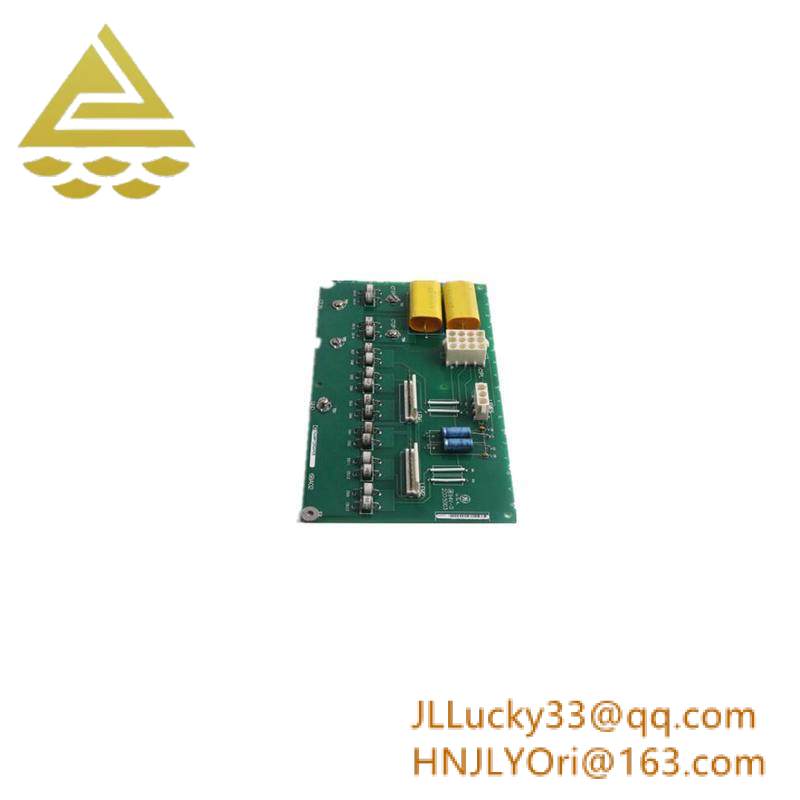

The DELTA TAU ACC-36E is a high-performance EtherCAT communication module designed for real-time motion control integration in advanced industrial automation systems. As part of DELTA TAU’s ACC series, a trusted platform for precision automation, the ACC-36E serves as a critical interface between motion controllers (e.g., DELTA TAU’s Clipper series) and distributed I/O devices, drives, and sensors. Its core function lies in enabling seamless, low-latency communication (≤1 ms cycle time) across EtherCAT networks, supporting up to 64 slave devices for complex multi-axis synchronization in applications like CNC machining, robotics, and semiconductor wafer handling.

trusted platform for precision automation, the ACC-36E serves as a critical interface between motion controllers (e.g., DELTA TAU’s Clipper series) and distributed I/O devices, drives, and sensors. Its core function lies in enabling seamless, low-latency communication (≤1 ms cycle time) across EtherCAT networks, supporting up to 64 slave devices for complex multi-axis synchronization in applications like CNC machining, robotics, and semiconductor wafer handling.

The DELTA TAU ACC-36E is a high-performance EtherCAT communication module designed for real-time motion control integration in advanced industrial automation systems. As part of DELTA TAU’s ACC series, a

trusted platform for precision automation, the ACC-36E serves as a critical interface between motion controllers (e.g., DELTA TAU’s Clipper series) and distributed I/O devices, drives, and sensors. Its core function lies in enabling seamless, low-latency communication (≤1 ms cycle time) across EtherCAT networks, supporting up to 64 slave devices for complex multi-axis synchronization in applications like CNC machining, robotics, and semiconductor wafer handling.

trusted platform for precision automation, the ACC-36E serves as a critical interface between motion controllers (e.g., DELTA TAU’s Clipper series) and distributed I/O devices, drives, and sensors. Its core function lies in enabling seamless, low-latency communication (≤1 ms cycle time) across EtherCAT networks, supporting up to 64 slave devices for complex multi-axis synchronization in applications like CNC machining, robotics, and semiconductor wafer handling.

What sets the ACC-36E apart is its ruggedized design and native compatibility with DELTA TAU’s PMAC (Programmable Multi-Axis Controller) software suite, which simplifies programming for trajectory planning, error compensation, and diagnostic monitoring. With a single EtherCAT port, the module ensures deterministic data exchange, making it ideal for high-speed robotic assembly lines or 5-axis CNC machines where sub-millisecond response times are critical. Hainan Jinlin Electromechanical, as a certified distributor, provides end-to-end support for integrating the ACC-36E into custom automation setups, ensuring compliance with CE and UL standards.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | DELTA TAU ACC-36E |

| Manufacturer | DELTA TAU |

| Product Type | EtherCAT Communication Module |

| Power Input | 24V DC (±10% tolerance) |

| Communication Protocol | EtherCAT (version 1.1) |

| Slave Device Support | Up to 64 |

| Operating Temperature | -20°C to 60°C |

| Protection Rating | IP20 (dust-protected) |

| Dimensions | 120mm (L) x 80mm (W) x 30mm (H) |

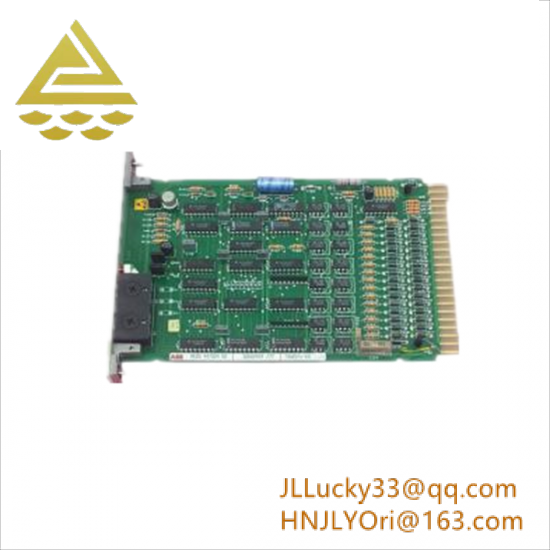

Key Features and Benefits

The ACC-36E combines hardware reliability with software flexibility to address the demands of modern motion control:

The ACC-36E combines hardware reliability with software flexibility to address the demands of modern motion control:

- Real-Time Communication: Leverages EtherCAT’s distributed clock synchronization to achieve ≤1 ms cycle times, ensuring precise coordination of multi-axis movements in robotic welding or semiconductor inspection systems.

- Scalable Architecture: Supports up to 64 slave devices, allowing seamless integration of drives, encoders, and HMIs without performance degradation.

- PMAC Integration: Works seamlessly with DELTA TAU’s PMAC software, enabling engineers to configure advanced motion profiles (e.g., electronic gearing, camming) and access real-time diagnostics via intuitive scripting.

- Industrial-Grade Durability: Withstand voltage fluctuations and extreme temperatures (-20°C to 60°C), reducing downtime in harsh factory environments.

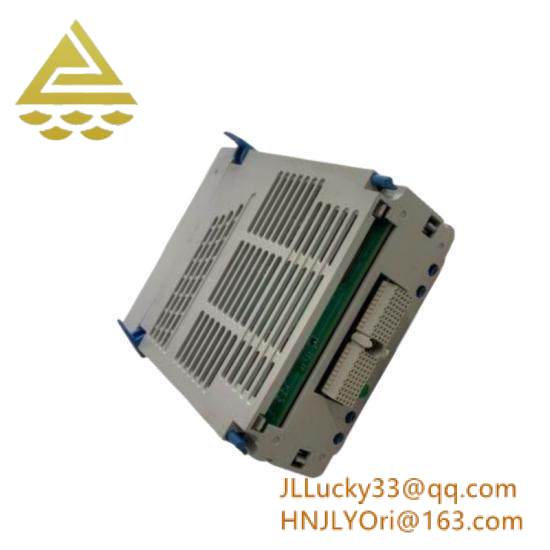

Hainan Jinlin Electromechanical’s pre-sales team offers tailored system design consultations, ensuring the ACC-36E aligns with your application’s scalability and latency requirements. Post-purchase, our technical experts provide 24/7 support, backed by a one-year warranty, to optimize performance and troubleshoot issues. This module’s combination of speed, reliability, and ease of integration makes it a cost-effective solution for upgrading legacy systems or building next-gen automation lines.

Related Models

DELTA TAU ACC-36E-2 – Dual-port variant of ACC-36E for daisy-chaining EtherCAT networks, ideal for large-scale robotic cells requiring redundant communication paths.

DELTA TAU CLIPPER 603926-101 – Multi-axis motion controller designed to pair with ACC-36E for high-precision CNC machining and robotic applications.

DELTA TAU ACC-12E – Compact EtherCAT module with basic I/O handling, suitable for smaller-scale systems requiring simplified communication.

DELTA TAU ACC-36E-3 – Enhanced version with extended temperature range (-30°C to 70°C), designed for outdoor or extreme industrial environments.

DELTA TAU ACC-36E-4 – Cybersecurity-hardened variant of ACC-36E, ensuring compliance with modern industrial safety standards for critical infrastructure.

DELTA TAU ACC-36E-2 – Dual-port variant of ACC-36E for daisy-chaining EtherCAT networks, ideal for large-scale robotic cells requiring redundant communication paths.

DELTA TAU CLIPPER 603926-101 – Multi-axis motion controller designed to pair with ACC-36E for high-precision CNC machining and robotic applications.

DELTA TAU ACC-12E – Compact EtherCAT module with basic I/O handling, suitable for smaller-scale systems requiring simplified communication.

DELTA TAU ACC-36E-3 – Enhanced version with extended temperature range (-30°C to 70°C), designed for outdoor or extreme industrial environments.

DELTA TAU ACC-36E-4 – Cybersecurity-hardened variant of ACC-36E, ensuring compliance with modern industrial safety standards for critical infrastructure.

As a certified partner of DELTA TAU, Hainan Jinlin Electromechanical specializes in delivering motion control solutions for automotive assembly lines, semiconductor fabs, and CNC machine tool retrofits. If ACC-36E does not meet your exact requirements, our team will source alternative models or recommend compatible third-party devices. Contact us via WhatsApp or email (jllucky33@qq.com) for personalized assistance.