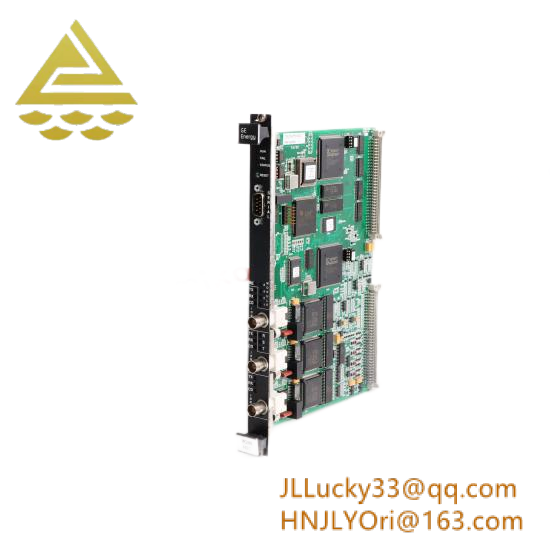

Industrial Refrigeration Control Module | GEA 0005-4050-429

Product Overview

The GEA 0005-4050-429 is a high-performance control module designed for seamless integration into industrial refrigeration and process cooling systems, a core offering from GEA, a global leader in thermal engineering solutions. This module excels in regulating temperature, pressure, and flow rates in critical applications such as food processing, pharmaceutical manufacturing, and chemical production, where precise thermal control is essential for product quality and safety. The GEA 0005-4050-429 stands out for its advanced algorithm-based control logic, real-time data processing capabilities, and compatibility with GEA’s ProControl series of automation systems. Its rugged design ensures reliable operation in harsh environments—including low temperatures and high humidity—while its modular architecture simplifies upgrades and maintenance. With a focus on accuracy, efficiency, and system integration, the GEA 0005-4050-429 optimizes thermal processes, reduces energy consumption, and enhances overall operational reliability.

Hainan Jinlin Mechanical & Electrical is a distributor of industrial control products, specializing in a wide range of brands. We possess extensive industry knowledge and market insights. Adhering to the “Customer First, Forge Ahead” business philosophy, we provide high-quality customer service. We’re here for you, dedicated to meeting your needs!

Technical Specifications

|

Parameter

|

Value

|

|

Product Model

|

GEA 0005-4050-429

|

|

Manufacturer

|

GEA

|

|

Product Type

|

Industrial Refrigeration Control Module

|

|

Control Signals

|

8 analog inputs, 6 analog outputs

|

|

Communication Protocol

|

Modbus RTU, Profibus DP

|

|

Operating Temperature

|

-10°C to +60°C

|

|

Power Supply

|

24V DC

|

|

Enclosure Rating

|

IP20 (panel-mounted)

|

Key Features and Benefits

The GEA 0005-4050-429 is engineered to deliver precise control in thermal management systems, combining technical sophistication with industrial durability. Its 8 analog inputs and 6 analog outputs enable comprehensive monitoring and regulation of critical parameters—such as refrigerant pressure, evaporator temperature, and flow rates—ensuring stable operation even in dynamic process conditions. This level of control is particularly valuable in food processing, where maintaining exact cooling temperatures prevents spoilage and ensures compliance with hygiene standards.

Advanced control logic is a standout feature: the module uses adaptive algorithms to optimize system performance, automatically adjusting to fluctuations in load or ambient conditions. For example, in pharmaceutical cold storage, the GEA 0005-4050-429 can fine-tune cooling output to maintain temperature stability within ±0.5°C, protecting sensitive medications. This adaptability not only improves product quality but also reduces energy waste by avoiding unnecessary overcooling.

Durability is built to withstand the demands of industrial environments, with a wide operating temperature range (-10°C to +60°C) that allows installation in both cold rooms and warm machine enclosures. Its compatibility with Modbus RTU and Profibus DP ensures seamless integration with GEA’s ProControl systems and third-party SCADA platforms, enabling centralized monitoring and remote adjustments—critical for reducing on-site maintenance in hard-to-reach areas.

The modular design simplifies servicing, allowing individual components to be replaced without system shutdowns, minimizing downtime. Backed by a one-year warranty, the GEA 0005-4050-429 offers a reliable, efficient solution for industrial thermal control, combining precision with long-term operational stability.

Related Models

- GEA 0005-4050-428 – Previous generation control module with reduced I/O channels, compatible with legacy GEA systems.

- GEA 0005-4050-430 – Enhanced version with 12 analog inputs, ideal for complex refrigeration systems with multiple zones.

- GEA 0005-4050-429-H – High-humidity variant, optimized for tropical or moisture-heavy environments like beverage production facilities.

- GEA 0005-4050-429-E – Ethernet-enabled model with IoT connectivity, supporting cloud-based monitoring for smart factory integration.

- GEA 0005-4060-429 – Safety-certified (SIL 2) control module, designed for hazardous refrigeration applications using flammable coolants.

- GEA 0005-4050-429-L – Low-power version, suitable for off-grid or energy-constrained installations such as remote cold storage units.

As a certified partner of GEA and other industry leaders, we provide expert pre-sales support to help integrate the GEA 0005-4050-429 into your thermal control system, including compatibility checks and configuration guidance. Our after-sales services include technical troubleshooting and software updates. All products come with a one-year warranty. For models not listed, contact us via WhatsApp: [https://wa.me/+86 19389860630] or Email: jllucky33@qq.com.