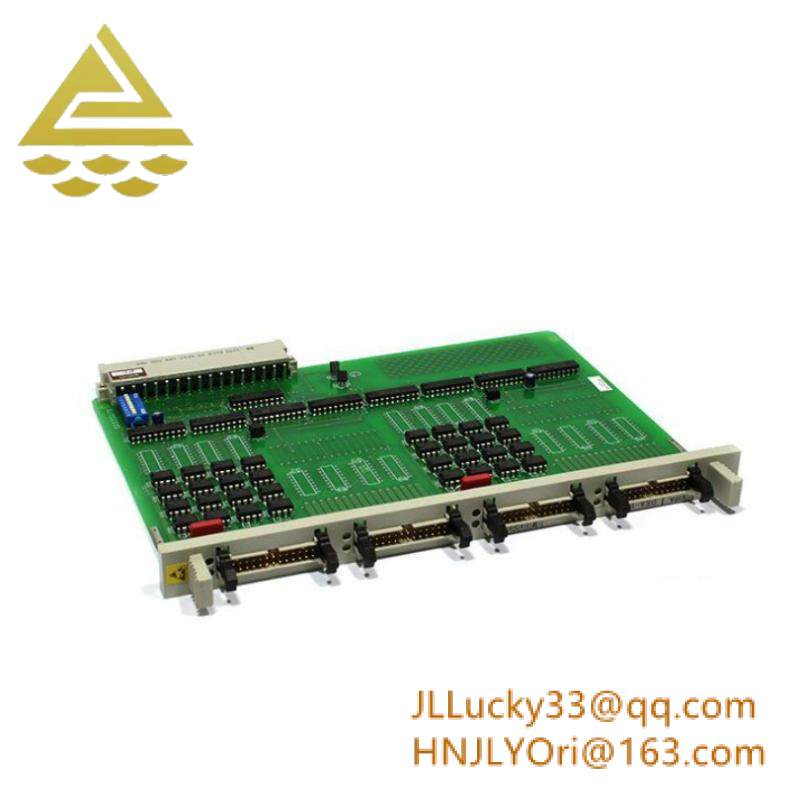

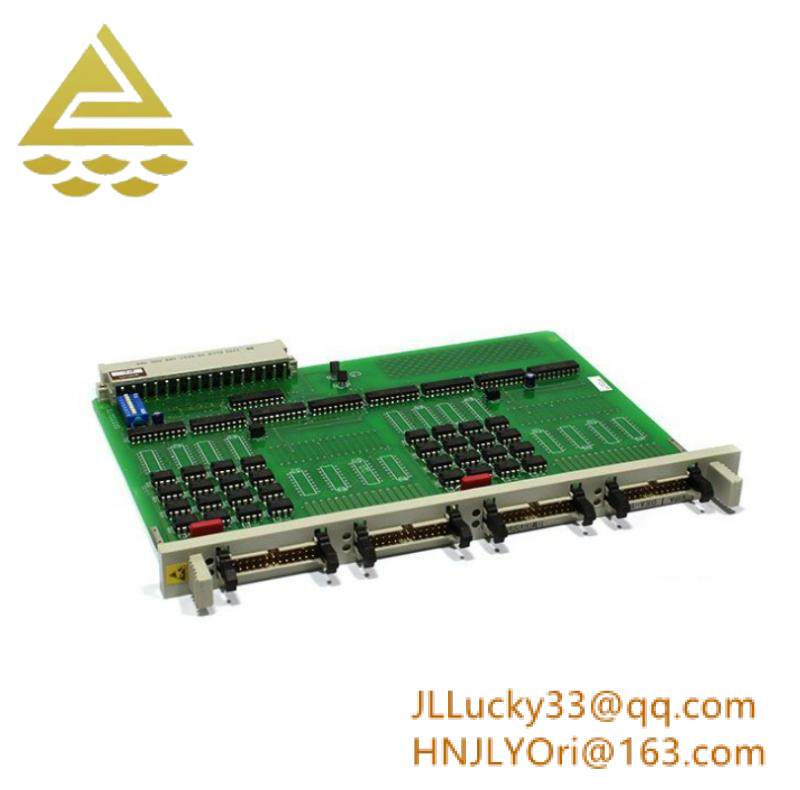

From a technical standpoint, the 2TLA020052R1000 stands out for its rugged design and adaptive functionality. It supports a wide range of motor ratings, making it suitable for both small-scale machinery and large industrial drives. The unit’s intuitive configuration interface and modular architecture allow engineers to tailor its settings to specific application needs, whether prioritizing energy savings, fault resilience, or remote monitoring capabilities. By combining robust hardware with intelligent software, ABB has created a solution that bridges the gap between basic motor control and advanced industrial automation, empowering businesses to future-proof their operations.

Technical Highlights Table

| Label | Specification |

|---|---|

| Model Number | 2TLA020052R1000 |

| Brand | ABB |

| Type | Modular Motor Control & Protection Unit |

| Input Voltage | 24 V DC (±20%) |

| Rated Current | Up to 100 A (adjustable via software) |

| Operating Temperature | -20°C to +60°C (with derating at high loads) |

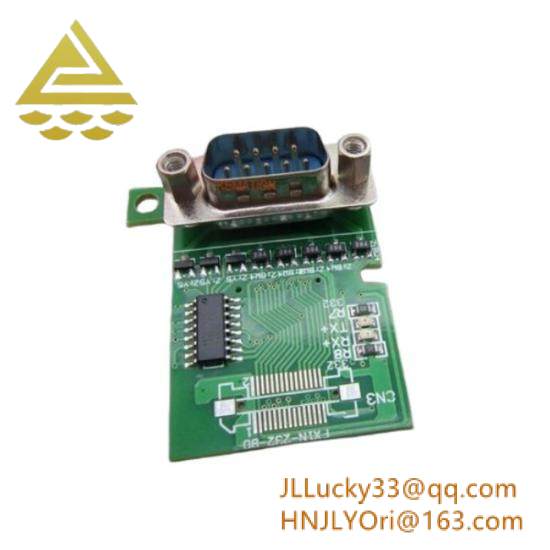

| Communication Methods | Ethernet (Modbus TCP), RS-485, Profibus DP |

| Mounting | DIN rail (35 mm) or panel mounting |

| Weight | 0.6 kg |

| Certifications | CE, UL, IEC 61439-2 (low-voltage switchgear) |

| Dimensions | 45 mm (W) × 120 mm (H) × 105 mm (D) |

| IP Rating | IP20 (indoor use, protected against dust) |

| Protection Functions | Overload, short-circuit, phase unbalance, earth fault |

| Protocols Supported | IEC 61131-3 programming for custom logic |

Functional Strengths & Design Advantages

The 2TLA020052R1000 is engineered to deliver unmatched reliability and flexibility in motor control applications. Its advanced protection algorithms continuously monitor motor current, voltage, and temperature, triggering instant shutdowns or alarms in the event of faults like phase loss or thermal overload—critical for preventing costly equipment damage. The unit’s adaptive start/stop control also minimizes inrush currents, reducing mechanical stress on motors and 延长 their service life. Engineers appreciate its plug-and-play compatibility with ABB’s motor starters and contactors, enabling rapid system commissioning without complex wiring or programming.

Durability is a core design principle of the 2TLA020052R1000. Its compact enclosure is built to withstand electromagnetic interference (EMI) from nearby machinery, a common issue in industrial environments, while the wide operating temperature range ensures stable performance in both freezing warehouses and high-heat production zones. The unit’s modular design further enhances its versatility: optional communication modules can be added to support protocols like Profinet or EtherNet/IP, adapting the system to evolving network requirements without replacing the entire unit.

Efficiency is another key strength. The 2TLA020052R1000 supports energy monitoring features, allowing operators to track motor power consumption and identify inefficiencies in real time. This data is invaluable for implementing energy-saving strategies, such as adjusting motor speed based on load requirements or scheduling maintenance during low-usage periods. Combined with its low power consumption and long operational lifespan, the unit delivers tangible cost savings over traditional motor control solutions.

Industrial Use Cases & Value Scenarios

The 2TLA020052R1000 excels in environments where precise motor control and robust protection are non-negotiable. In manufacturing plants, it serves as the backbone for conveyor systems, ensuring smooth material flow by regulating motor speed and detecting belt jams or overloads. For example, in an automotive assembly line, the unit monitors each conveyor motor’s performance, preventing downtime caused by unexpected faults and ensuring just-in-time production remains on schedule.

In the energy sector, the 2TLA020052R1000 plays a critical role in managing pumps and compressors in substations and renewable energy installations. It ensures these high-power devices start and stop safely, while its remote monitoring capabilities allow technicians to adjust parameters from off-site—a vital feature for maintaining grid stability in wind farms or solar plants. Similarly, in water treatment facilities, the unit controls pumps that manage water distribution and wastewater processing, ensuring compliance with environmental regulations by preventing motor failures that could disrupt treatment processes.

Leave a comment

Your email address will not be published. Required fields are marked *