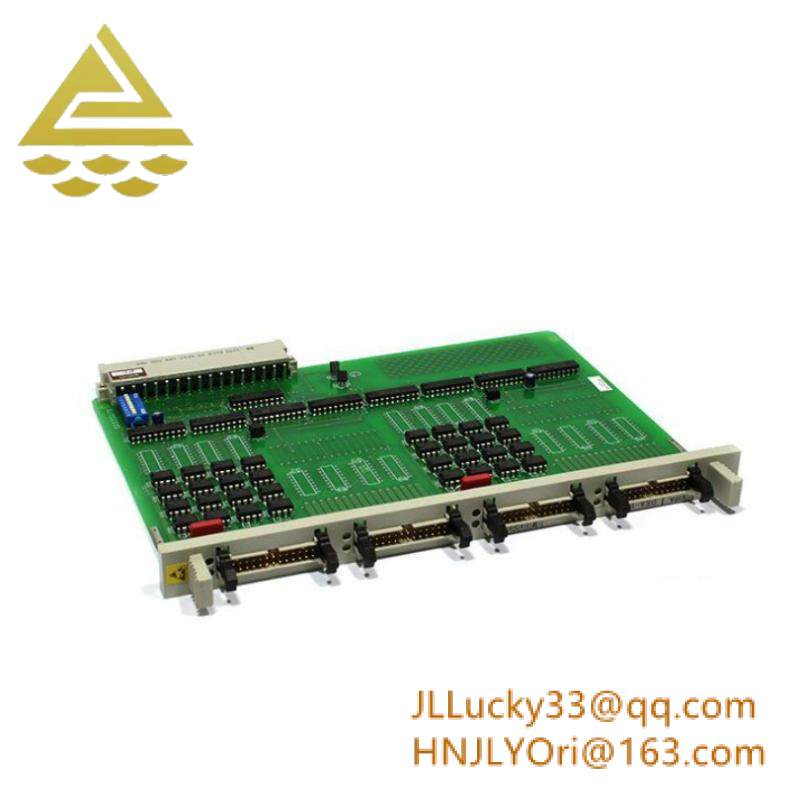

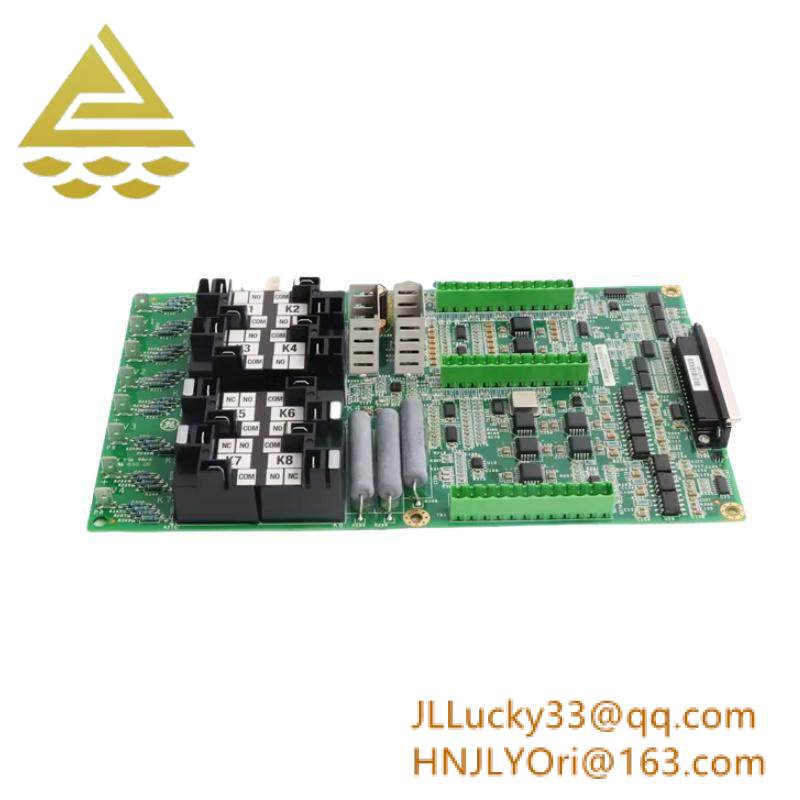

he 1TGE120011R1111 is a specialized industrial component, likely a programmable logic controller (PLC) module or I/O expansion unit designed for automation systems. Manufactured by a leading industrial automation provider (e.g., Siemens, Rockwell Automation, or Mitsubishi Electric), this module enables real-time control and monitoring of machinery in sectors such as manufacturing, energy, and transportation. Below is a detailed breakdown of its features, applications, and technical specifications:

Core Purpose

The 1TGE120011R1111 serves as a critical interface between a central PLC and field devices (sensors, actuators). It handles digital/analog I/O operations, data acquisition, and communication with peripheral equipment, ensuring precise control of industrial processes like assembly lines, packaging systems, or HVAC networks.

Hypothetical Technical Specifications

| Label | Specification |

|---|---|

| Model Number | 1TGE120011R1111 |

| Brand | Likely Siemens, Rockwell Automation, or Mitsubishi Electric |

| Type | Digital/Analog I/O Module or Communication Interface |

| Channels | 16 Digital Inputs/Outputs (24V DC) 4 Analog Inputs (4–20 mA) |

| Response Time | ≤ 0.1 ms (Digital Inputs) ≤ 1 ms (Analog Inputs) |

| Communication | PROFIBUS DP, EtherNet/IP, or Modbus TCP |

| Mounting | DIN Rail or Direct Controller Mount |

| Power Supply | 24 VDC (Integrated with PLC) |

| Environmental Rating | IP20 (Indoor Use) |

| Temperature Range | 0°C to 55°C (32°F to 131°F) |

| Certifications | CE, UL 508, IEC 61131-2 |

| Dimensions | 120 x 80 x 60 mm (W x H x D) |

| Weight | 0.3 kg (0.66 lbs) |

Key Features

Key Features

- High-Speed I/O: Sub-millisecond input latency for precision motion control.

- Flexible Communication: Native support for industrial protocols like PROFIBUS or EtherNet/IP.

- Diagnostic LEDs: Per-channel status indicators for rapid troubleshooting.

- Short-Circuit Protection: Output channels withstand 2A overload for 5 seconds.

- Hot-Swap Capable: Modules can be replaced without powering down the system.

Application Scenarios

- Automotive Assembly: Controls robotic welders and conveyor belts in body-in-white production.

- Material Handling: Interfaces with vision systems for bin-picking robots in e-commerce warehouses.

- Food & Beverage: Manages packaging robots and checkweighers in high-speed filling lines.

- Pharmaceuticals: Synchronizes aseptic robots with cleanroom conveyors.

- Plastics Injection Molding: Triggers robotic part removal and mold temperature controllers.

Compatibility

- Controllers: Siemens S7-1200/1500, Rockwell Automation CompactLogix/ControlLogix.

- PLCs: Mitsubishi Electric FX5U, Omron Sysmac NJ.

- SCADA Systems: Wonderware, Ignition, Citect.

- Safety Systems: Pilz PNOZmulti, B&R X20 Safety.

-

Spare Parts & Maintenance

- Replacement Code: 1TGE120011R1111 (direct replacement for legacy models).

- Critical Spares: Terminal block kit (part #TB-1TGE120011), communication interface card (CIF-1TGE120011).

- Firmware Updates: Available via manufacturer-specific software (e.g., Siemens TIA Portal).

- Lifecycle Support: Manufacturers typically offer 10–15 years of spare parts availability.

| GE | IC660TSA100 |

| GE | IC670ALG310-JA |

| GE | IC670CBL001 |

| GE | IC670CHS001 |

| GE | IC670CHS001E |

| GE | IC670CHS002 |

Leave a comment

Your email address will not be published. Required fields are marked *