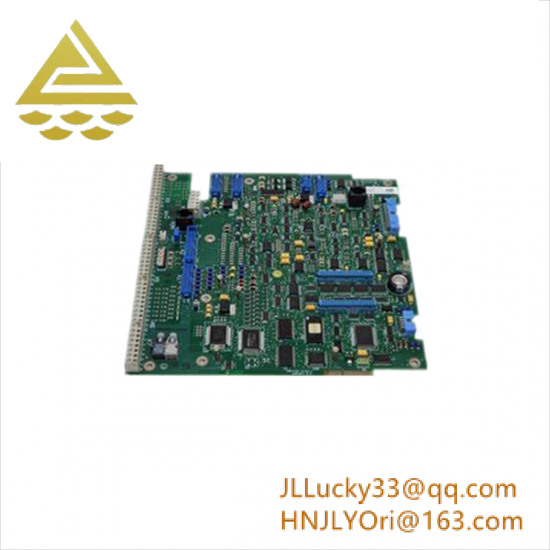

Product Overview

The 140CPU65160 is a high-performance central processing unit (CPU) from Schneider Electric’s Quantum series, designed for complex industrial automation systems. As the core control component, this CPU delivers robust processing power and reliability for managing critical operations in manufacturing, energy, and process industries. Part of the Quantum platform, the 140CPU65160 integrates seamlessly with modular I/O systems, enabling real-time data processing, logic control, and communication across distributed networks. Its value lies in its ability to handle high-speed applications, support redundant configurations, and ensure system stability even in harsh industrial environments. The 140CPU65160 typically serves as the brain of automation setups, coordinating machine functions, optimizing workflow efficiency, and facilitating predictive maintenance through advanced diagnostic capabilities. This model stands out for its balance of processing speed, memory capacity, and compatibility with industry-standard protocols, making it a cornerstone for scalable and reliable control systems.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | 140CPU65160 |

| Manufacturer | Schneider Electric |

| Product Type | Industrial PLC CPU (Central Processing Unit) |

| Processor Type | 32-bit RISC processor |

| Memory | 8 MB user program memory, 8 MB data memory |

| Communication Protocols | Modbus, Ethernet/IP, Quantum Data Highway (QDH), Profibus |

| Power Supply | 24V DC (±10%) |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to 85°C (-40°F to 185°F) |

| Dimensions | 114 mm (H) x 25 mm (W) x 175 mm (D) |

| Mounting Method | Rack-mounted (DIN rail) |

| Protection Class | IP20 (indoor use) |

| I/O Support | Up to 16,384 I/O points (via expansion modules) |

Key Features and Benefits

The 140CPU65160 140CPU65160 offers the industrial sector several critical advantages that enhance operational efficiency. Its high-speed processing capability ensures rapid execution of complex logic programs, reducing cycle times and improving machine responsiveness. The CPU’s built-in redundancy support—such as hot standby and automatic failover—minimizes downtime in mission-critical applications, making it ideal for systems where reliability is non-negotiable. Additionally, the model features advanced self-diagnostic functions that monitor hardware health, detect faults, and provide real-time error reporting, enabling proactive maintenance and reducing troubleshooting time.

In terms of flexibility, the 140CPU65160140CPU65160 supports multiple programming languages (including ladder logic, structured text, and function block diagrams), catering to diverse engineering preferences. Its compatibility with Schneider Electric’s Unity Pro software simplifies system configuration, programming, and commissioning. The CPU also prioritizes cybersecurity with embedded access control and data encryption, safeguarding against unauthorized system intrusion. Furthermore, its modular design allows seamless integration with existing Quantum components, facilitating system upgrades without major overhauls. These features combined make the 140CPU65160 a future-proof solution for industries demanding high-performance, secure, and adaptable automation control.

Application Scenarios

The 140CPU65160thrives in a wide range of industrial environments where precise, reliable control is essential. In manufacturing, it powers assembly lines for automotive plants, managing robotic arms, conveyor systems, and quality inspection stations to ensure consistent production output. In oil and gas refineries, the CPU oversees complex processes like distillation and pipeline monitoring, operating in harsh conditions while maintaining real-time data exchange with supervisory control and data acquisition (SCADA) systems.

For power generation facilities, the 140CPU65160 regulates turbine operations, grid synchronization, and energy distribution, ensuring stable power supply. It also excels in water treatment plants, controlling pumps, valves, and filtration systems to optimize water quality and flow rates. In smart infrastructure, such as metro rail networks, the CPU manages train signaling, platform screen doors, and environmental control systems for safe and efficient transit. Its ability to handle high I/O counts and support redundant networks makes it suitable for any application requiring continuous operation, from food and beverage processing to pharmaceutical manufacturing. By integrating the 140CPU65160, industries can achieve higher productivity, reduced operational costs, and enhanced system visibility.

Related Models

- 140CPU65260 – Higher-performance variant with increased memory and processing speed for complex applications.

- 140CPU43412 – Entry-level Quantum CPU for smaller-scale systems with basic control needs.

- 140CPU67160 – Redundant CPU model designed for fault-tolerant systems requiring zero downtime.

- 140CPU65150 – Previous generation model with similar functionality but lower memory capacity.

- 140XBP01600 – Quantum backplane compatible with 140CPU65160 for modular system expansion.

- 140NOE77101 – Ethernet communication module to enhance network connectivity for the 140CPU65160.

- 140CPS11420 – Power supply unit designed to complement the 140CPU65160 in Quantum control systems.

Installation and Maintenance

Installation Preparation: Before installing the 140CPU65160, ensure the mounting area is free of dust, moisture, and vibrations, as these can impact performance. The CPU mounts vertically on a DIN rail within a control cabinet, requiring at least 25 mm of clearance on all sides for proper ventilation. Grounding the cabinet to industry standards (e.g., IEC 60364) is crucial to prevent electrical interference. Verify the power supply matches the CPU’s 24V DC requirements and that all wiring complies with local electrical codes. Connecting the CPU to a Quantum backplane should follow manufacturer guidelines to ensure secure module alignment and communication.

Maintenance Recommendations: Regular maintenance of the 140CPU65160 involves periodic visual inspections for loose connections or physical damage. Use diagnostic tools within Unity Pro software to monitor CPU health, including memory usage, processor load, and error logs. Perform firmware updates as recommended by Schneider Electric to address security patches and feature enhancements. In dusty environments, clean the CPU’s ventilation slots quarterly to prevent overheating. While the CPU is designed for long-term reliability, consider having a spare 140CPU65160 on hand for critical systems to minimize replacement delays in the event of a failure. Always power down the system and follow ESD (electrostatic discharge) precautions when handling the CPU.

Product Warranty

Schneider Electric stands behind the 140CPU65160 with a comprehensive warranty that reflects its commitment to quality and durability. The product is guaranteed against defects in materials and workmanship for a period of [insert standard warranty duration, e.g., “two years”] from the date of purchase. During this period, Schneider Electric will repair or replace any faulty components at no cost, provided the product is used in accordance with operational guidelines. Customers benefit from global technical support, including access to online resources, product documentation, and expert assistance to address installation, configuration, or maintenance queries. The warranty underscores the 140CPU65160’s reliability in demanding industrial settings and reinforces Schneider Electric’s dedication to customer satisfaction, ensuring peace of mind for users investing in this automation solution.

Leave a comment

Your email address will not be published. Required fields are marked *