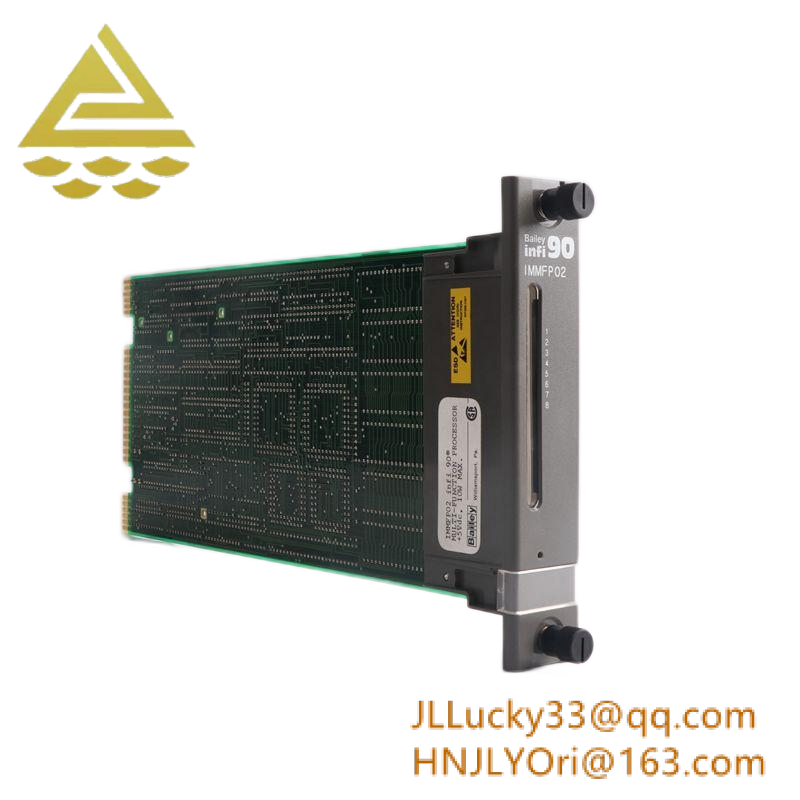

Product Overview

The 140CPU11303 is a that forms an integral part of the Schneider Electric Modicon Quantum automation platform. This platform is widely recognized in the industrial automation domain for its reliability and versatility.

Functionally, the 140CPU11303 is responsible for executing control logic, processing data, and managing communication within an industrial control system. With its advanced architecture, it can handle a wide range of control applications, from discrete and analog control to complex process control scenarios. In an automation setup, it serves as the brain, coordinating the activities of various input/output (I/O) modules and other components. What makes the 140CPU11303 truly valuable is its ability to offer high – speed processing, ensuring real – time response in industrial processes. It also provides excellent compatibility with a vast array of industrial devices, making it suitable for both new installations and retrofitting existing systems.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | 140CPU11303 |

| Manufacturer | Schneider |

| Product Type | CPU Module |

| Processor | Intel 80186 |

| Clock Speed | 20 MHz |

| Memory | 368 kb Internal RAM |

| Communication Ports | 1 Modbus Plus, 1 Modbus RS232 |

| I/O Points (Distributed) | 30 I / 32 O |

| I/O Points (Max Local) | 64 I / 64 O |

| I/O Points (Remote) | 64 I / 64 O |

| Networking (Distributed Networks) | Up to 3 |

| Networking (Remote Networks) | Up to 2 |

| Battery Type | Lithium, 7 µA – 210 µA |

| Battery Capacity | 1.2 Ah |

| Battery Life | 10 years |

| Operating Temperature | 0 – 60°C (32 – 140°F) |

| Storage Temperature | – 40 – 85°C (- 40 – 185°F) |

| Humidity | 95% without condensation |

| Operating Altitude | ≤ 5000 m (≤ 16404.2 ft) |

Key Features and Benefits

The 140CPU11303 comes with several remarkable features that set it apart in the industrial automation landscape. Its high – performance Intel 80186 processor enables rapid execution of control programs. With a clock speed of 20 MHz, it can handle complex algorithms and large amounts of data in real – time, ensuring smooth operation of industrial processes.

In terms of memory, the 368 kb of internal RAM provides ample space for storing both the control logic and the data being processed. This is crucial for applications that require significant computational power and data storage capabilities.

The module’s communication capabilities are also a major strength. The inclusion of one Modbus Plus and one Modbus RS232 port allows for seamless integration with other devices in the industrial network. This makes it easy to connect to sensors, actuators, HMIs, and other control systems, facilitating efficient data transfer and system – wide communication.

The 140CPU11303 is highly reliable, with a long – lasting lithium battery that has a capacity of 1.2 Ah and a lifespan of 10 years. This battery backup ensures that important data is not lost during power outages, maintaining the integrity of the control system. Additionally, its robust construction and wide operating temperature range make it suitable for use in harsh industrial environments.

Application Scenarios

The 140CPU11303 finds extensive use across various industries. In the manufacturing sector, it is commonly employed in discrete manufacturing lines. For example, in an automotive assembly plant, the 140CPU11303 can be used to control the movement of robotic arms that perform tasks such as welding, painting, and part assembly. It precisely coordinates the actions of different components in the production line, ensuring high – quality and efficient manufacturing.

In the oil and gas industry, it plays a vital role in refineries. It can be used to monitor and control the complex processes involved in refining crude oil, such as distillation, cracking, and chemical reactions. The 140CPU11303 can process data from numerous sensors placed throughout the refinery, adjusting process parameters in real – time to optimize production and ensure safety.

Power plants also rely on the 140CPU11303 for their control systems. It can manage the generation, distribution, and monitoring of electrical power. For instance, it controls the operation of turbines, generators, and other power – related equipment, ensuring stable power output and efficient plant operation. In smart infrastructure projects, like intelligent building management systems, the 140CPU11303 can be used to control lighting, heating, ventilation, and air – conditioning systems, providing energy – efficient and comfortable environments.

Related Models

- 140CPU11303S – An upgraded version with expanded IEC programming capacity. This model is ideal for applications that require more advanced programming features and greater flexibility in implementing complex control strategies.

- 140CPU43412 – A more powerful variant with higher processing speed and larger memory capacity. It is suitable for large – scale industrial projects where more computational resources are needed to handle extensive control tasks.

- 140CPU65160 – Offers enhanced networking capabilities compared to the 140CPU11303. This makes it a better choice for applications that involve complex network architectures and require high – speed data transfer between multiple devices.

- 140CPU53414 – Features improved diagnostic capabilities, allowing for quicker identification and resolution of system faults. This is beneficial for industries where system uptime is critical, such as pharmaceutical manufacturing.

- 140CPU11300 – An earlier generation model with basic functionality. It may be used in less complex industrial setups or as a cost – effective solution for projects with limited requirements.

Installation and Maintenance

Installation preparation for the 140CPU11303 requires ensuring an appropriate physical space. It should be installed in a location that allows for proper ventilation to prevent overheating, as it operates within a specific temperature range. The mounting method typically involves using standard DIN – rail mounting, which is a common and convenient way to secure the module in an industrial control panel. Grounding is also crucial to protect the module from electrical surges and ensure safe operation. The installation environment should be free from excessive dust, moisture, and electromagnetic interference.

For maintenance, regular checks should be carried out. This includes monitoring the module’s operating temperature, as overheating can lead to performance degradation. Checking the communication ports for any signs of damage or poor connection is also important. Diagnostic software can be used to periodically assess the module’s health, looking for any error codes or abnormal behavior. As for replacement intervals, while the 140CPU11303 is designed for long – term use, the lithium battery should be replaced every 10 years as per its lifespan. In case of any hardware failures, it is advisable to consult Schneider Electric’s official documentation or contact their support team for proper replacement procedures.

Product Warranty

Schneider Electric stands behind the quality of the 140CPU11303 with a comprehensive warranty. The module is covered against defects in materials and workmanship for a specified period. This warranty not only gives customers confidence in the product’s quality but also reflects Schneider Electric’s commitment to customer satisfaction. In the unlikely event of a problem, their global support network is readily available. Customers can reach out to their local support centers or use online resources for assistance. Whether it’s troubleshooting, getting replacement parts, or seeking technical advice, Schneider Electric’s support team is dedicated to resolving issues promptly. This ensures that the 140CPU11303 continues to perform optimally throughout its lifespan, minimizing downtime and maximizing the efficiency of industrial operations.

Leave a comment

Your email address will not be published. Required fields are marked *